Construction method of glass reinforced plastic septic tank

A technology of glass tempering and fiberglass, which is applied in biological sludge treatment, etc., can solve problems such as insufficient contact with feces, easy leakage, and polluted water quality, and achieve enhanced overall structural strength and bearing capacity, enhanced sealing effect, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

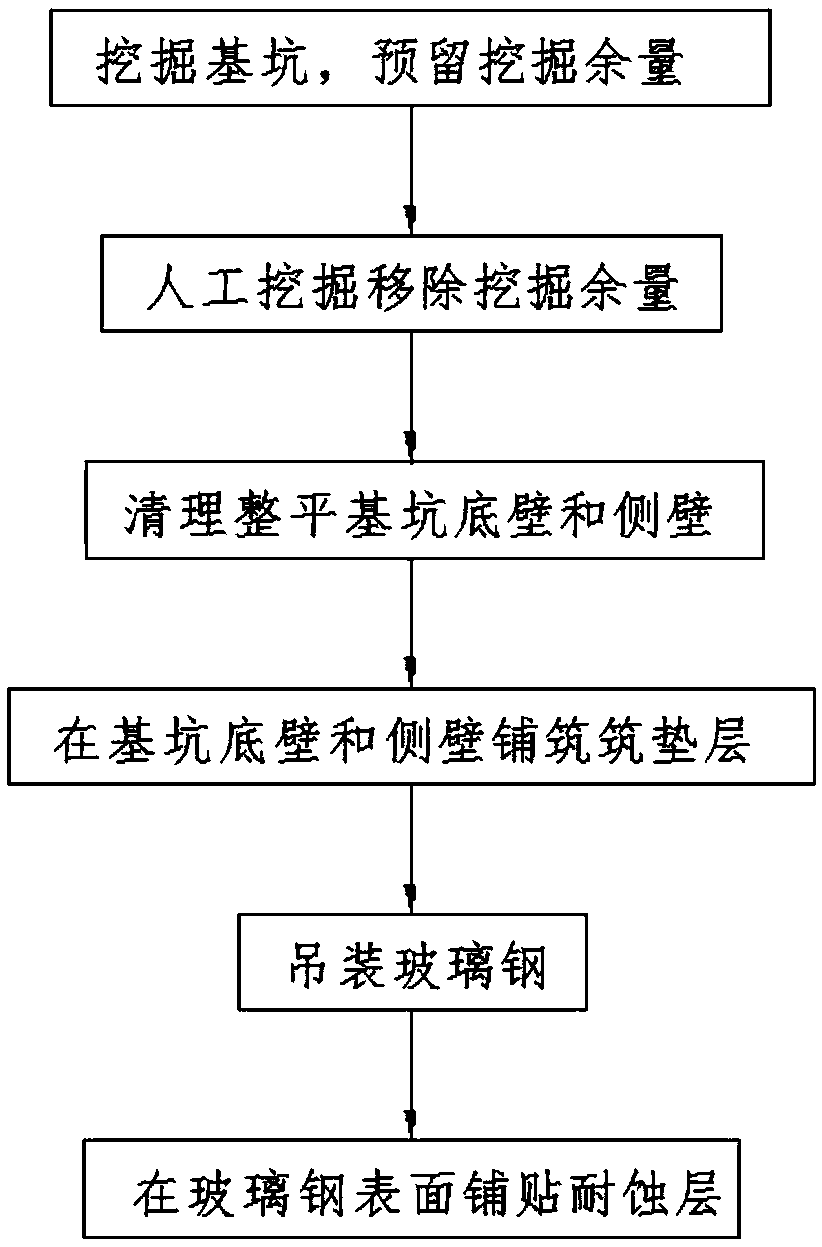

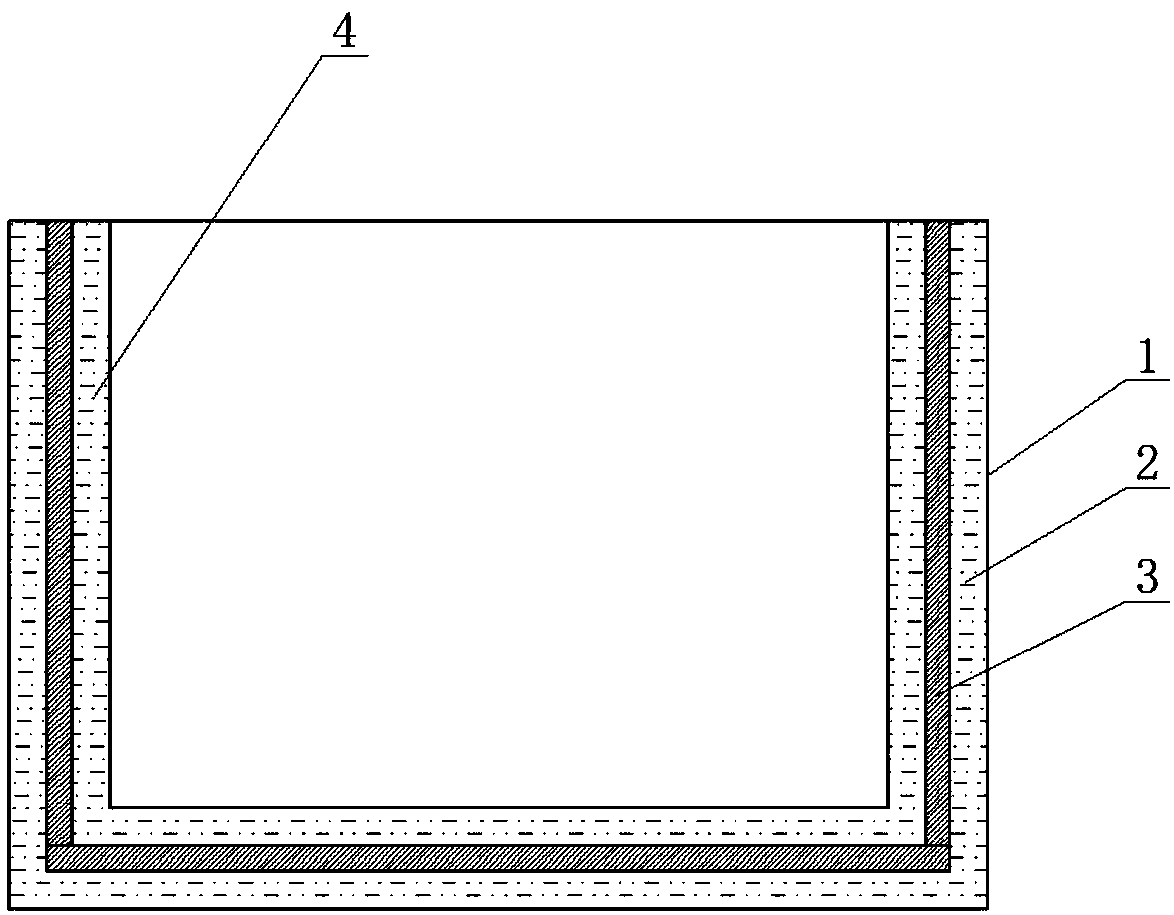

[0025] The invention provides a method for building a glass reinforced plastic septic tank, such as figure 1 , figure 2 shown, including the following steps:

[0026] Step 1: Excavate the foundation pit 1 on the ground, and reserve an excavation margin of appropriate depth at the bottom of the foundation pit 1; further, preferably, the depth of the foundation pit 1 is 0.8m-2m. The excavation allowance depth is 20cm.

[0027] Step 2: Use the method of manual mining to excavate and remove the excavation margin in step 1;

[0028] Step 3: Remove all stones within the foundation pit 1, level and tamp the bottom wall and side walls of the foundation pit 1; pay special attention to clearing sharp stones and some boulders with sharp edges and corners, so as to avoid damage to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap