A kind of water-soluble polyether amide carboxylate with defoaming and lubricating functions and its synthesis method

A technology of polyetheramide carboxylate and synthesis method, applied in lubricating compositions, additives, petroleum industry and other directions, can solve the problem that the lubricating properties of pure polyether fully synthetic cutting fluid cannot meet the machining requirements, affect the normal progress of machining, The problem of foam overflowing the storage tank, etc., to achieve the effect of improving amidation efficiency, good lubricity and small foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

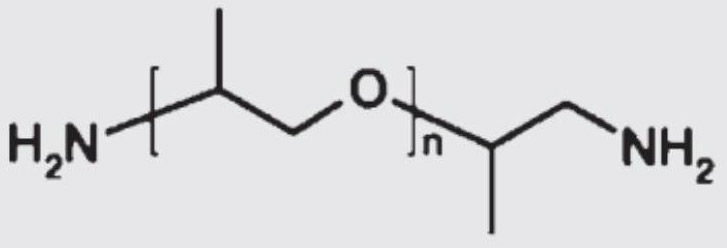

Method used

Image

Examples

Embodiment 1

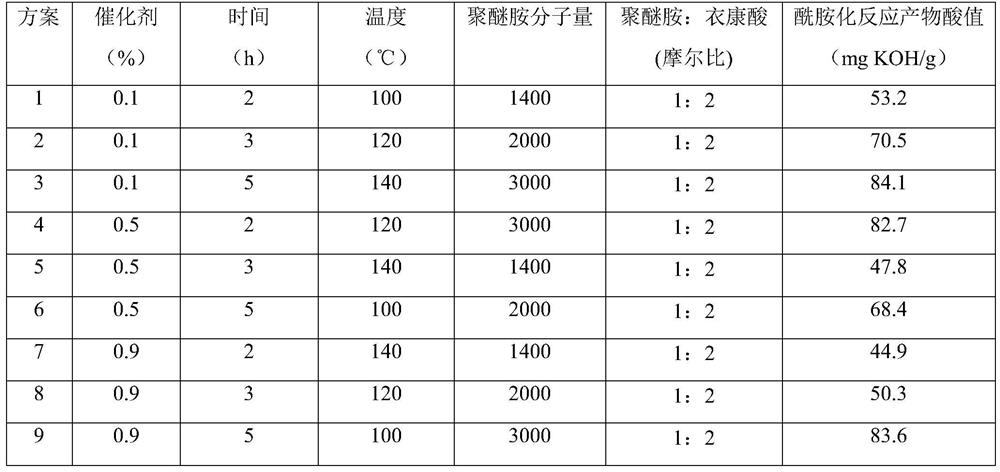

[0048] Weigh 140g of polyetheramine with a molecular weight of 1400 and add it to a flat-bottomed flask, add 26g of itaconic acid while stirring, add 1.494g of p-toluenesulfonic acid catalyst after stirring evenly, heat while stirring, and the nitrogen flow rate is 5-10Nm 3 / h, control the temperature at 140°C, and react for 2 hours to obtain the amidation product, and the acid value of the amidation product is 44.9 mg KOH / g;

[0049] When the amidation product is cooled to 60-80°C, add 33.9g of diisopropanolamine to the amidation product, and react under normal pressure at 60-80°C for 40 minutes to obtain the final product.

Embodiment 2

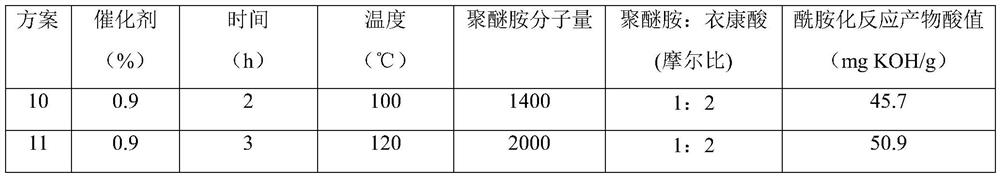

[0051] Weigh 140g of polyetheramine with a molecular weight of 1400 and add it into a flat-bottomed flask, add 26g of itaconic acid while stirring, add 1.494g of paraformaldehyde catalyst after stirring evenly, heat while stirring, and the nitrogen flow rate is 5-10Nm 3 / h, control the temperature at 100°C, and react for 2 hours to obtain the amidation product, and the acid value of the amidation product is 45.7mg KOH / g;

[0052] When the temperature of the amidated product drops to 60-80°C, add 17.8g of AMP95 to the amidated product, and react under normal pressure at 60-80°C for 40 minutes to obtain the final product.

Embodiment 3

[0054] Weigh 200g of polyetheramine with a molecular weight of 2000 and add it into a flat-bottomed flask, add 26g of itaconic acid while stirring, add 2.034g of paraformaldehyde catalyst after stirring evenly, heat while stirring, and the nitrogen flow rate is 5-10Nm 3 / h, control the temperature at 120°C, and react for 3 hours to obtain the amidation product, and the acid value of the amidation product is 50.9 mg KOH / g;

[0055] When the temperature of the amidated product drops to 60-80°C, add 17.8g of AMP95 to the amidated product, and react under normal pressure at 60-80°C for 40 minutes to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com