A kind of fireproof polymer composite material and preparation method thereof

A composite material and polymer technology, which is applied in the field of fire-resistant polymer composite materials and their preparation, can solve problems such as being unable to withstand continuous high-temperature flame burning, achieve strong physical and mechanical properties, improve flame-retardant and fire-resistant effects, and have good flame-retardant properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

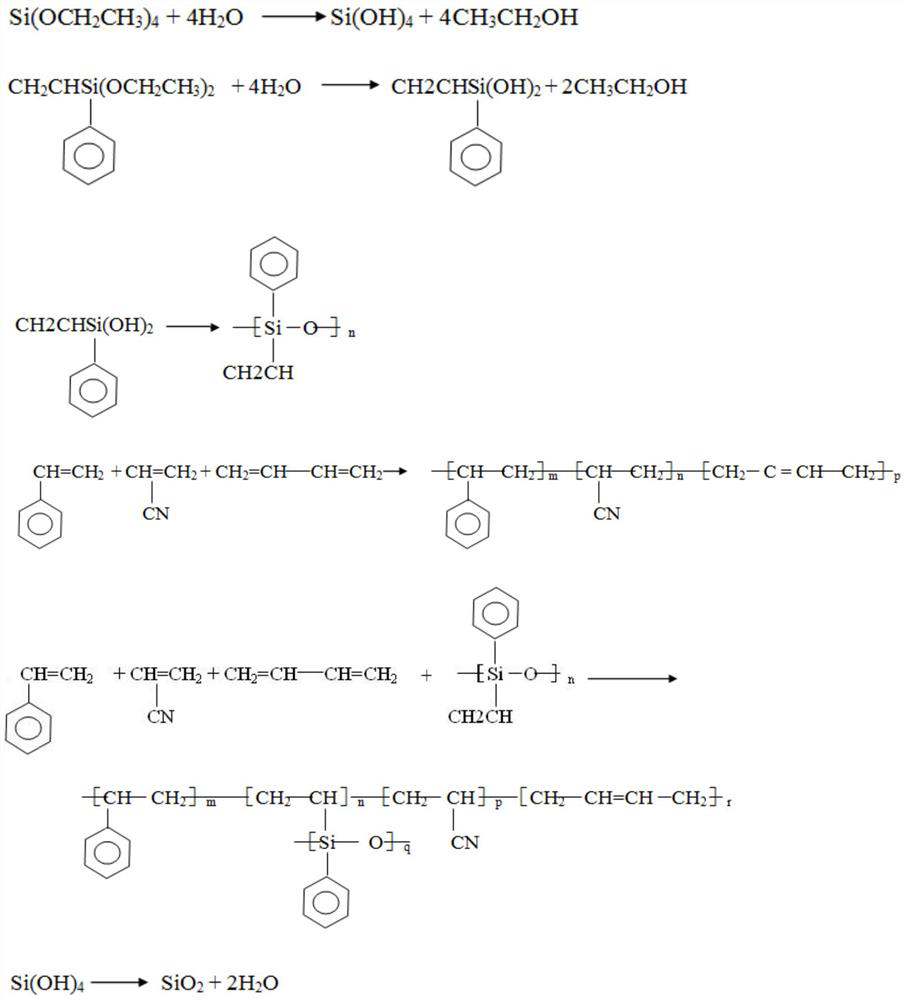

[0021] A method for preparing a fireproof polymer composite material, comprising the following steps in sequence:

[0022] Step 1. Mix the silane hydrolyzate, styrene, acrylonitrile, and polymerization initiator uniformly according to the required ratio, then add 1,3-butadiene, and polymerize at 85–95°C until the system viscosity reaches 200– Dry after 300cp to obtain organosilicon / polymer hybrid material;

[0023] Step 2: Mix the organosilicon / polymer hybrid material and additives obtained in Step 1 evenly according to the required ratio, and then put them into an extruder to extrude and granulate.

[0024] In step one, the preparation method of the silane hydrolyzate is:

[0025] Stir the silane and water according to the required ratio first, then add the catalyst and stir until the system is clear and transparent.

[0026] In step 2, the extrusion process of the extruder is: 180±5°C in the first zone, 200±5°C in the second zone, 220±5°C in the third zone, 230±5°C in the ...

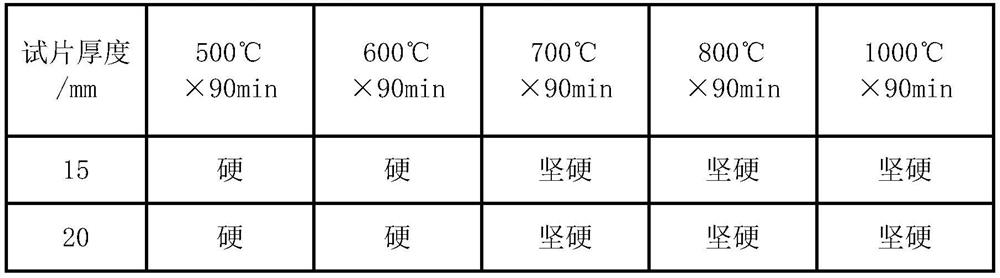

Embodiment 1

[0033] A kind of fireproof polymer composite material, its raw material composition is: organosilicon / polymer hybrid material 80, antioxidant 1010 0.3, antioxidant 168 0.3, wherein, the raw material composition of described organosilicon / polymer hybrid material It is: silane hydrolyzate 10, styrene 5, acrylonitrile 5, 1,3-butadiene 5, polymerization initiator 0.2, the raw material composition of the silane hydrolyzate is: vinylphenyldiethoxysilane 0.6, Tetraethoxysilane 6, catalyst 1, water 2, the polymerization initiator is dibenzoyl peroxide, and the catalyst is dilute hydrochloric acid with a concentration of 0.15mol / L.

[0034] The preparation method of the above-mentioned fireproof polymer composite material is carried out in accordance with the following steps:

[0035] Step 1. First add vinylphenyldiethoxysilane, tetraethoxysilane and water in the airtight container according to the required proportion, then seal and stir for 30 minutes, then add dilute hydrochloric aci...

Embodiment 2

[0039] The difference with Example 1 is:

[0040] The raw material composition of the fireproof polymer composite material is: organosilicon / polymer hybrid material 90, antioxidant 10100.4, antioxidant 168 0.4, wherein the raw material composition of the organosilicon / polymer hybrid material is: Silane hydrolyzate 12, styrene 7.5, acrylonitrile 7.5, 1,3-butadiene 7.5, polymerization initiator 0.4, the raw material composition of the silane hydrolyzate is: vinylphenyldiethoxysilane 0.7, tetraethyl Oxysilane 7, Catalyst 2, Water 3.

[0041]In the second step, the polymerization reaction temperature is 85° C., and the viscosity of the polymerization system is 300 cp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com