Method for manufacturing a silicon wafer

a manufacturing method and silicon wafer technology, applied in the field of silicon wafers, can solve the problems of increasing the leakage current in the manufactured device, increasing the complexity or advance of the technique for removing or capturing metal elements, and breaking wires, and achieves the effect of increasing the carbon density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[A] First Embodiment of the Invention

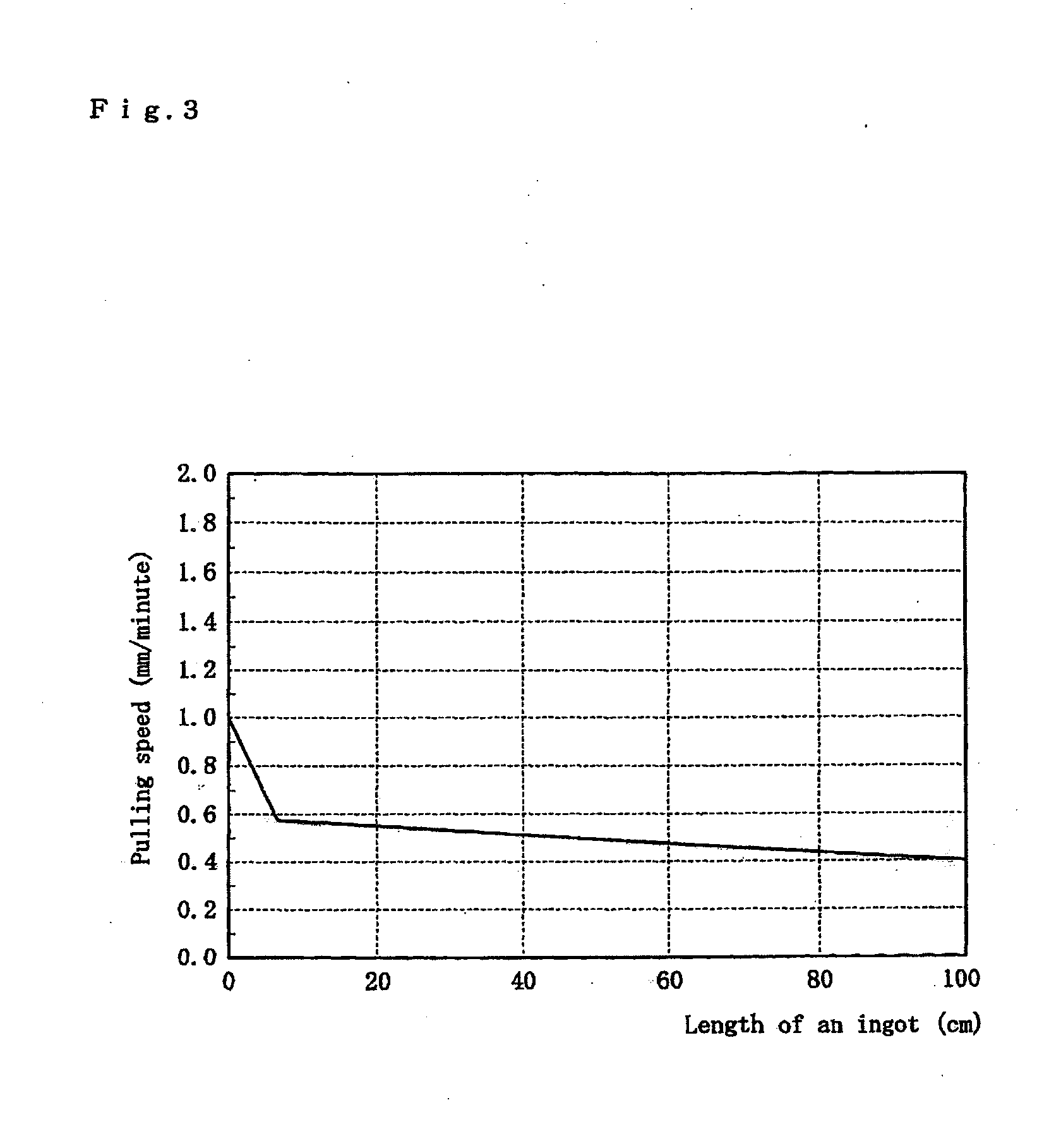

[0047]A silicon wafer according to first to third embodiments of the present invention is made by pulling an ingot at a specified pulling speed profile based upon Voronkov theory from a molten silicon liquid inside a hot zone furnace by the CZ method and then slicing this ingot.

[0048]A method for manufacturing a single crystal silicon ingot containing less amount of metal element and having no defect according to the first embodiment of the present invention is described.

(1) Method for Manufacturing a Single Crystal Silicon Containing Less Amount of Metal Element

[0049]A method for manufacturing a single crystal silicon ingot according to the first embodiment of the present invention, said ingot containing less amount of metal particularly iron, comprises a process of cleaning block-shaped or grain-shaped polycrystalline silicon to be raw material, a single crystal silicon pulling process of melting the cleaned material silicon and growing a singl...

second embodiment

[B] Second Embodiment of the Invention

[0068]A silicon wafer of a second embodiment of the present invention is made by pulling an ingot under a specified condition from a molten silicon liquid inside a hot zone furnace by means of the CZ method in the same way as the first embodiment and then slicing this ingot.

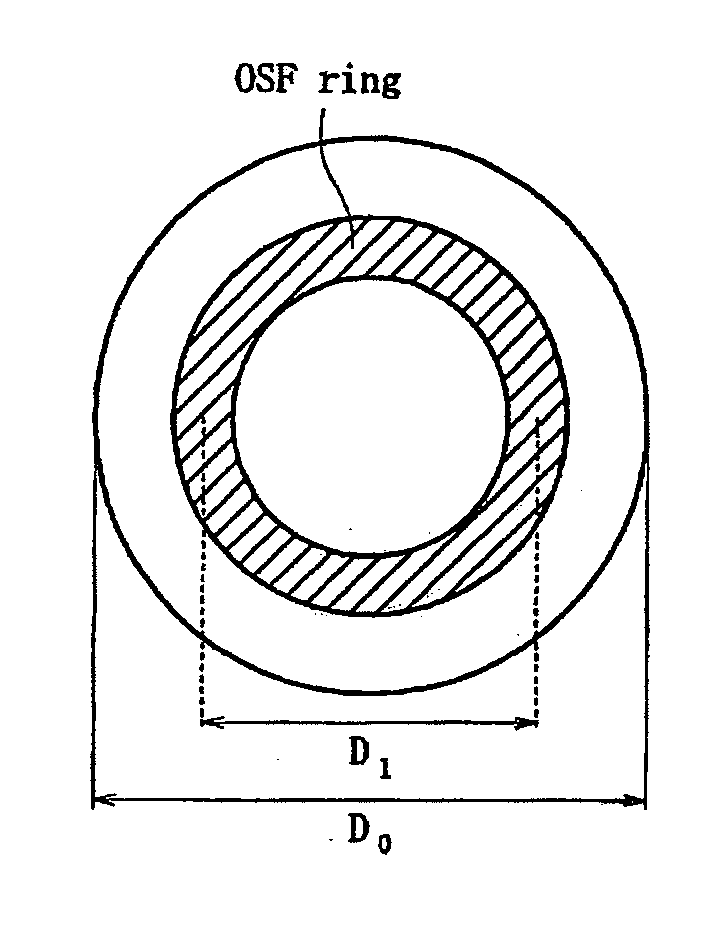

[0069]As described above, this CZ silicon wafer sometimes has OSF in the shape of a ring when it receives a thermal oxidation process. This OSF ring expands toward the outer circumference as the V / G value increases, and reduces its ring diameter and becomes disk-shaped in the center of the wafer and then disappears as the V / G value decreases.

[0070]This fact is described with reference to FIG. 9A. FIG. 9A shows a vertical section of an ingot obtained by gradually reducing the pulling speed and continuously decreasing the value of V / G. This ingot has been pulled as being doped with boron at a density of 1×1015 atoms / cm3 so that its conduction type is a p type and its resistivit...

third embodiment

[C] Third Embodiment of the Invention

[0083]A silicon wafer of a third embodiment of the present invention is made by pulling an ingot under a specified condition from a molten silicon liquid inside a hot zone furnace by means of the CZ method in the same way as the first embodiment and then slicing this ingot.

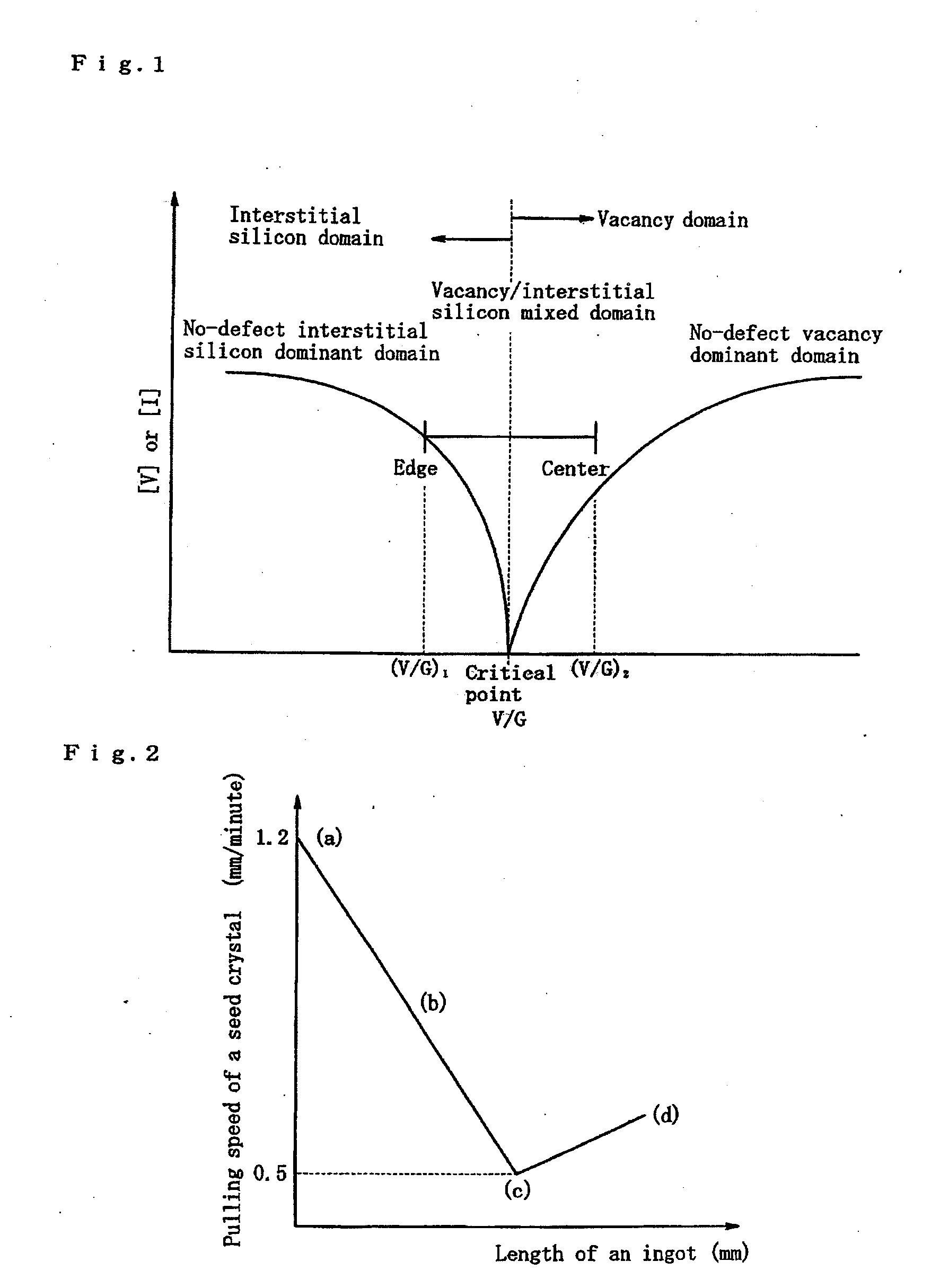

[0084]FIG. 13 is a characteristic diagram corresponding to FIG. 1 of the first embodiment. Here, it is described that there is a domain ((V / G)2 to (V / G)3) for forming an OSF nucleus in a domain [V] adjacent to a domain [P] and that a perfect domain [P] is further classified into a domain [P1] and a domain [PV]. This domain ((V / G)2 to (V / G)3) is a small domain of a domain in which vacancy point defects dominantly exist, said small domain being adjacent to a perfect domain, and is a domain in which no COP nor L / D is generated in the wafer. Domain [P1] is a domain where the ratio of V / G ranges from said (V / G)1 to the critical point, and domain [PV] is a domain where the ratio of V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com