Composite automotive clean gasoline and preparation method thereof

A compound vehicle and compound technology, applied in the field of gasoline, can solve the problems of poor miscibility between compound alcohols and hydrocarbon gasoline, easy stratification, atmospheric resistance, etc., and achieve low production costs, reduce air resistance, and reduce production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A compound clean gasoline for vehicles, its raw material is made up of the following components by weight fraction, 60 parts of gasoline, 20 parts of ethanol, 3 parts of methyl alcohol, 14 parts of surfactant, 3 parts of composite additive; The component of described composite additive And the weight fraction is 60 parts of solubilizer, 5 parts of corrosion inhibitor, 5 parts of antioxidant, 20 parts of synergist, 1 part of antiwear agent, and 9 parts of catalyst.

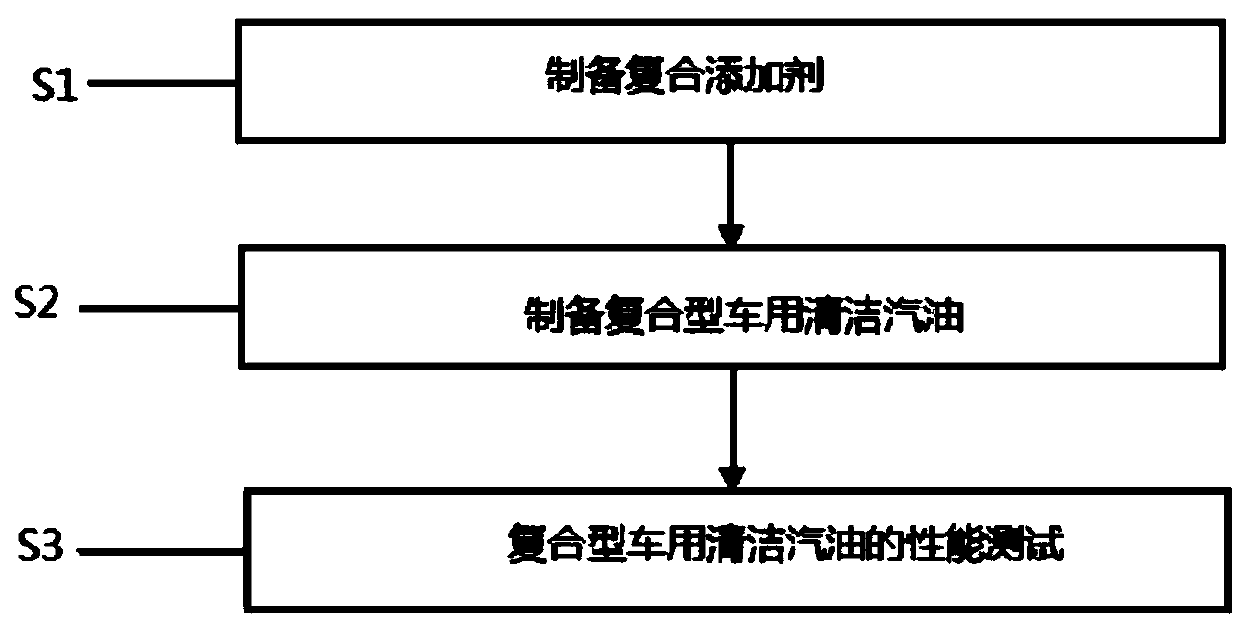

[0044] Such as figure 1 Shown, a kind of preparation method of composite type vehicle clean gasoline, its method is specifically as follows:

[0045] S1: Preparation of composite additives

[0046] The corrosion inhibitor N, N'-disalicylidene-propylenediamine, the antioxidant 2,6-di-tert-butyl-p-methylphenol, the synergist tetrahydrofuran, the anti-wear agent organophosphide, and the catalyst were sequentially added to the A reaction vessel containing solubilizing agent pentanol, wherein the volume ratio o...

Embodiment 2

[0057] A compound clean gasoline for vehicles, its raw material is made up of the following components by weight fraction, 68 parts of gasoline, 17 parts of ethanol, 4 parts of methyl alcohol, 8.5 parts of surfactants, 2.5 parts of composite additives; the component of described composite additives And the weight fraction is 70 parts of solubilizer, 3 parts of corrosion inhibitor, 2.2 parts of antioxidant, 17 parts of synergist, 0.8 part of antiwear agent, and 7 parts of catalyst.

[0058] Such as figure 1 Shown, a kind of preparation method of composite type vehicle clean gasoline, its method is specifically as follows:

[0059] S1: Preparation of composite additives

[0060] The corrosion inhibitor N, N'-disalicylidene-propylenediamine, the antioxidant 2,6-di-tert-butyl-p-methylphenol, the synergist tetrahydrofuran, the anti-wear agent organophosphide, and the catalyst were sequentially added to the A reaction vessel containing solubilizing agent pentanol, wherein the volu...

Embodiment 3

[0072] A compound clean gasoline for vehicles, its raw material is made up of the following components by weight fraction, 75 parts of gasoline, 15 parts of ethanol, 5 parts of methyl alcohol, 3 parts of surfactant, 2 parts of composite additive; The component of described composite additive And the weight fraction is 80 parts of solubilizer, 1 part of corrosion inhibitor, 1.3 parts of antioxidant, 10 parts of synergist, 0.7 part of antiwear agent, and 7 parts of catalyst.

[0073] Such as figure 1 Shown, a kind of preparation method of composite type vehicle clean gasoline, its method is specifically as follows:

[0074] S1: Preparation of composite additives

[0075] The corrosion inhibitor N, N'-disalicylidene-propylenediamine, the antioxidant 2,6-di-tert-butyl-p-methylphenol, the synergist tetrahydrofuran, the anti-wear agent organophosphide, and the catalyst were sequentially added to the A reaction vessel containing solubilizer amyl alcohol, wherein the volume ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com