A recovery method for valuable components in vanadium slag

A recovery method, vanadium slag technology, applied in the field of metallurgy, to achieve the effect of low production cost, reduced production cost and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

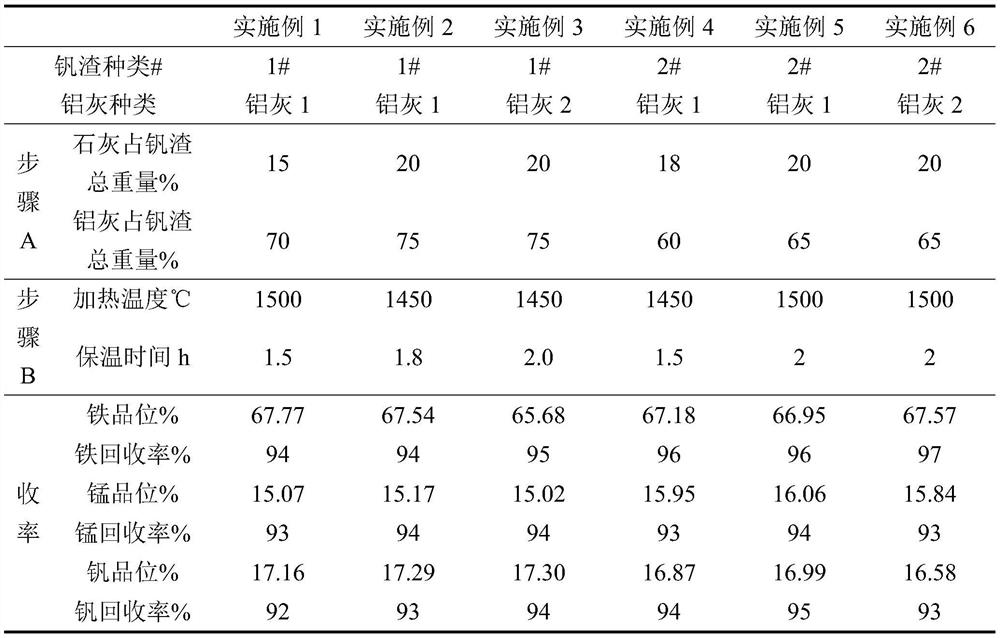

Embodiment 1

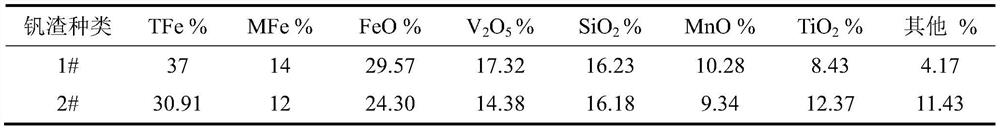

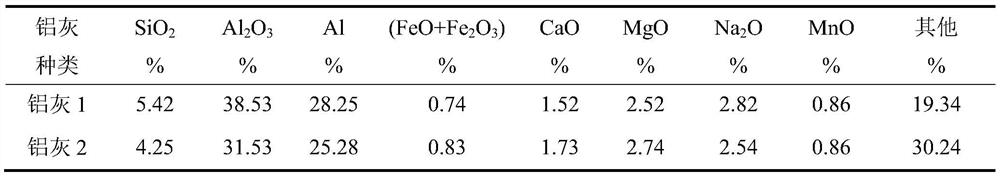

[0042] Using 1# molten converter vanadium slag, its composition is TFe 37.00%, MFe 14.00%, FeO 29.57%, V 2 o 5 17.32%, SiO 2 16.23%, MnO 10.28%, TiO 2 8.43%, other 4.17%; aluminum ash 1 component is SiO 2 5.42%, Al 2 o 3 38.53%, Al 28.25%, (FeO+Fe 2 o 3 ) 0.74%, CaO 1.52%, MgO 2.52%, Na 2 O2.82%, MnO 0.86%, others 19.34%.

[0043] The method for comprehensive recycling of vanadium slag and aluminum ash valuable components comprises the following steps:

[0044] A. Raw material preparation and charging: Prepare molten vanadium slag, lime and aluminum ash, first put lime and aluminum ash into the electric furnace, then pour molten vanadium slag, the amount of lime and aluminum ash added is 15% of the total weight of vanadium slag And 70%, particle size ≤ 100 mesh.

[0045] B. Heating reduction: After charging, heat the electric furnace to 1500°C and keep it warm for 1.5 hours to reduce the valuable components iron, manganese and vanadium in aluminum ash and vanadium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com