Self-elevating conveying and distributing system and construction method of cast roller compacted concrete dam

A technology of roller compacted concrete and distribution system, applied in construction, water conservancy engineering, marine engineering and other directions, can solve the problems of concrete strength increase, influence the increase of concrete strength, mutual interference, etc., to improve the efficiency of closing warehouse and reduce material transfer The effect of uniform thickness of links and fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

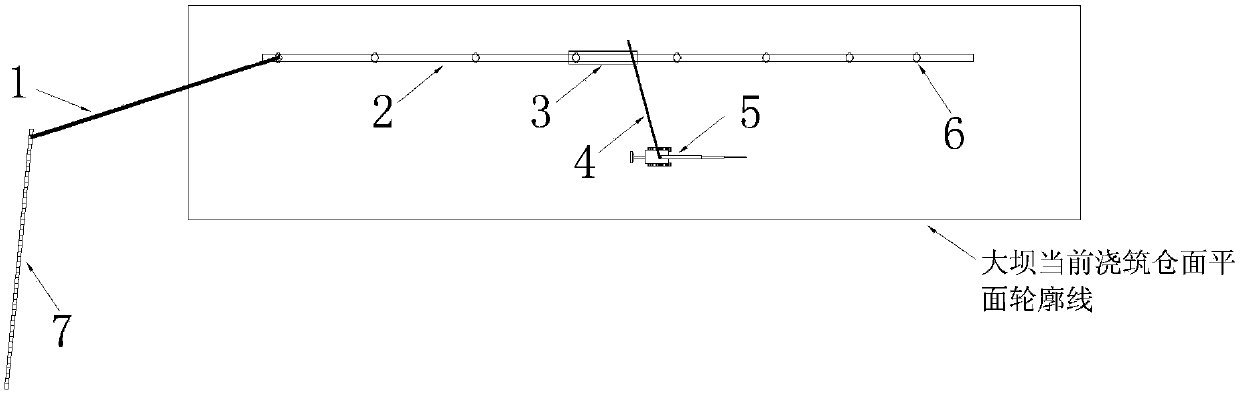

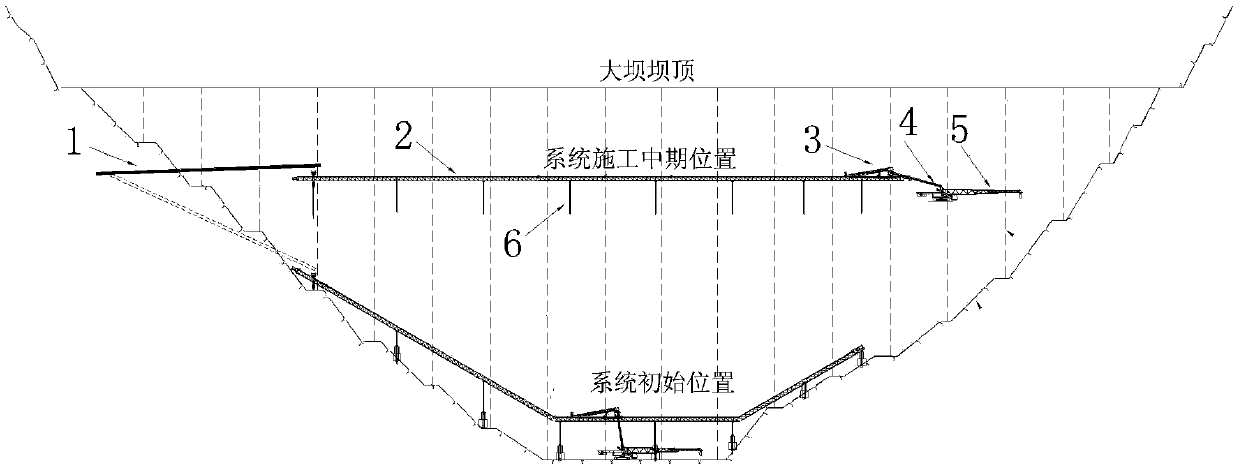

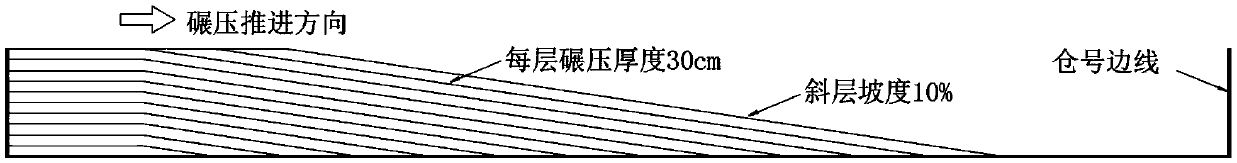

[0043] Such as figure 1 and figure 2 As shown, the self-elevating material conveying and distributing system for pouring a roller compacted concrete dam, the system includes a feeding device 7 outside the dam, a transition belt 1 inside and outside the dam, a conveying belt 2 inside the dam, a walking unloader 3, and a connecting Belt 4, crawler type distribution machine 5 and feeding belt lifting device 6:

[0044]The feeding device 7 outside the dam is connected to the transition belt 1 inside and outside the dam, and can transport the RCC material mixed by the mixing station to the transition belt 1 inside and outside the dam between the inside and outside of the dam;

[0045] The transition belt 1 inside and outside the dam is connected to the conveying belt 2 in the dam, and can transport the roller compacted concrete material to the conveying belt 2 in the dam;

[0046] The conveying belt 2 in the dam can realize synchronous rise with the dam surface through the suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com