A pulsed plasma thruster working fluid supply assembly

A pulsed plasma and thruster technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of unfavorable micro-integration, poor stability, etc., to improve mechanical reliability, reduce damping, and high mechanical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

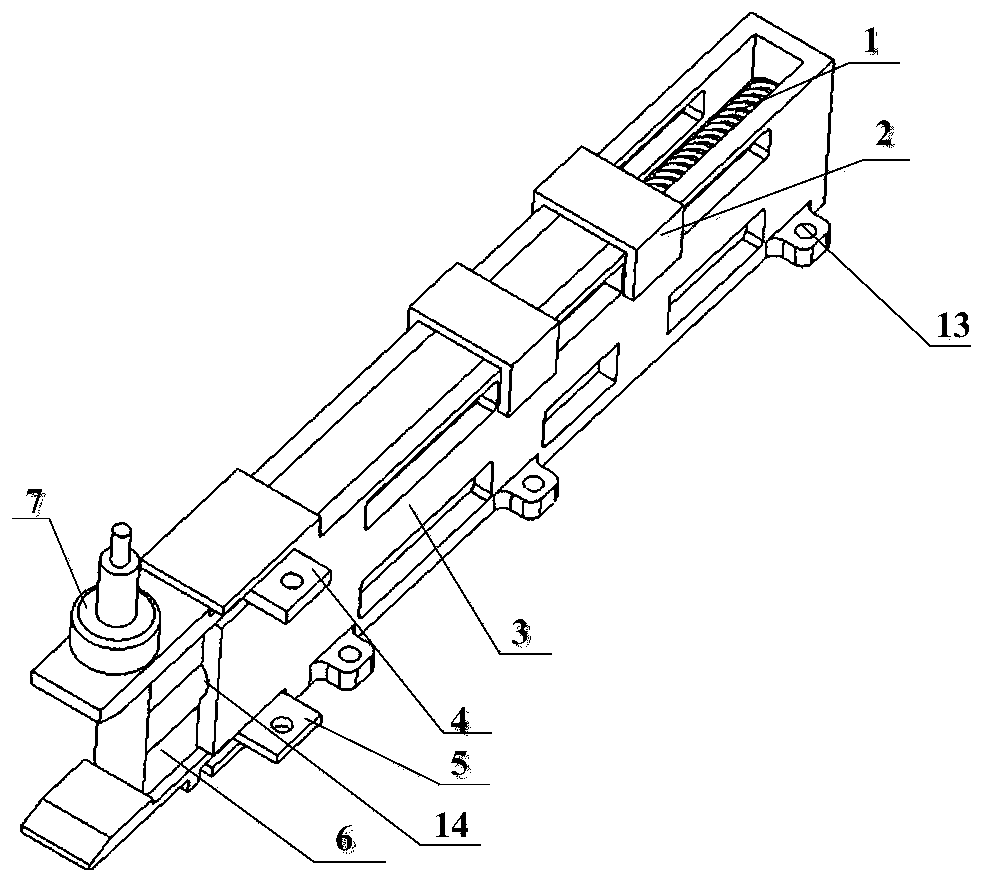

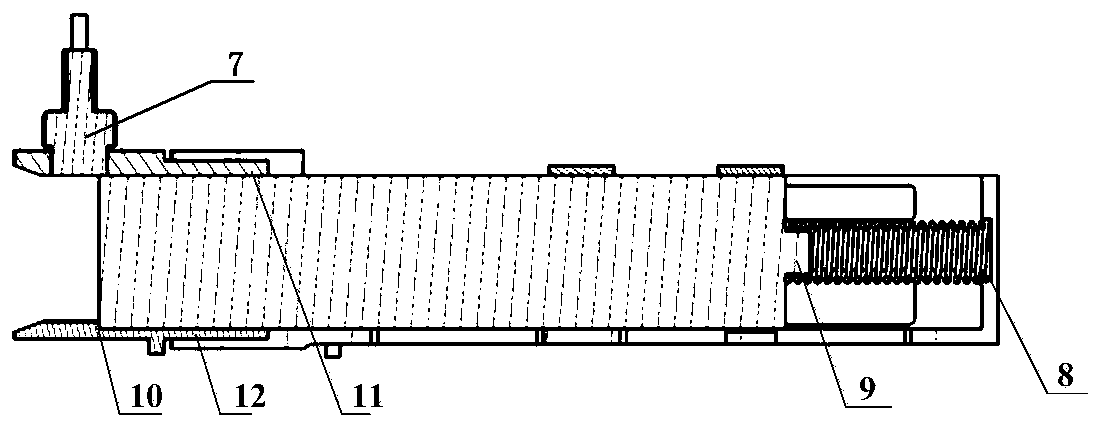

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0027] A pulse plasma thruster working medium supply assembly of the present invention includes a coil spring 1, a working medium carrying box 3, a spark plug 7, a cathode plate 11, and an anode plate 12; the working medium carrying box 3 has a The cavity corresponding to the shape and structure of the working medium 6 is used to place the working medium 6; one end surface of the working medium 6 along the length direction is provided with a constraining boss 9, and two end surfaces along the width direction are respectively provided with a protrusion One end of the coil spring 1 is connected to the restraining boss 9, and the other end is in contact with the inner wall of one end of the working medium carrying box 3; the other end of the working medium carrying box 3 is open, and the upper end of the opening is provided with a cathode plate 11, the spark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com