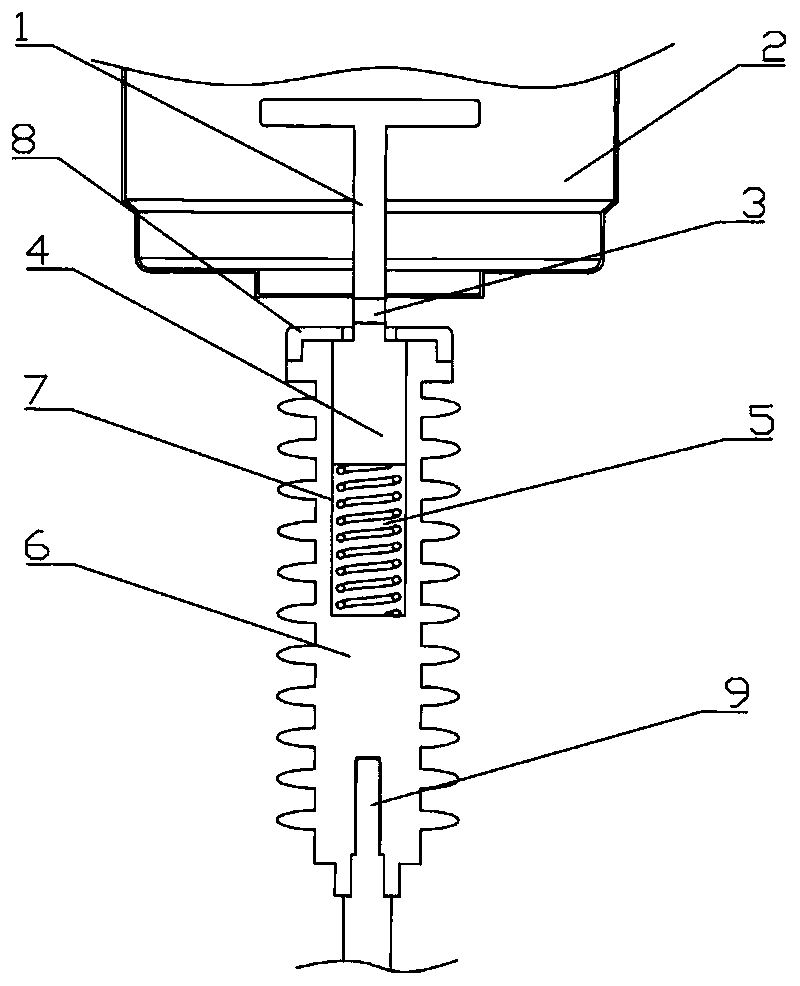

An insulating pull rod for a circuit breaker

A technology for insulating pull rods and circuit breakers, which is applied in the direction of high-voltage air circuit breakers, circuits, protective switch operation/release mechanisms, etc. It can solve the problems of affecting insulation characteristics, increasing the size of parts, increasing the size of machinery, etc., to improve anti-aging Performance, excellent mechanical strength, and the effect of enhancing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: skeleton preparation one:

[0030] Prepare the backbone as follows:

[0031] Equivalent amount of Et 3 NHCl and anhydrous CuCl 2 Mix and stir at room temperature, and heat at 80°C until the solids are completely dissolved to obtain an organic amine-type copper-based ion solution;

[0032] Put 2000g of powdered polyamide into the kneader, heat at 60°C for 20min, then add 80ml of organic amine-type copper-based ion solution, mix well and heat to 150°C for kneading, after kneading for 20min, add saturated chloride 80ml of iron solution, 100g of decabromodiphenyl ether, heat to 190°C and carry out secondary mixing, the time of secondary mixing is 15min, after completion, add 20g of boric acid, stir evenly, vacuum defoaming for 80min, after defoaming is completed, use The extruder extrudes polyamide fibers. The temperature settings of the extruder from front to back are 215°C, 225°C, 235°C, 245°C, and 255°C. The head temperature is set at 258°C to extrude 0....

Embodiment 2

[0034] Embodiment 2: skeleton preparation two:

[0035] Prepare the backbone as follows:

[0036] Equivalent amount of Et 3 NHCl and anhydrous CuCl 2 Mix and stir at room temperature, and heat at 80°C until the solids are completely dissolved to obtain an organic amine-type copper-based ion solution;

[0037] Put 1500g of powdered polyamide into the kneader, heat at 70°C for 15min, then add 50ml of organic amine-type copper-based ion solution, mix well and heat to 155°C for kneading, after kneading for 15min, add saturated chloride 60ml of iron solution, 60g of decabromodiphenyl ether, heated to 192°C and then mixed for the second time, the time for the second mixing is 13min, after completion, add 20g of boric acid, stir evenly, vacuum degassing for 70min, after degassing is completed, use The extruder extrudes polyamide fiber. The temperature settings of the extruder from front to back are 217°C, 227°C, 237°C, 247°C, and 256°C. The head temperature is set at 259°C to extrud...

Embodiment 3

[0039] Embodiment 3: skeleton preparation three:

[0040] Prepare the backbone as follows:

[0041] Equivalent amount of Et 3 NHCl and anhydrous CuCl 2 Mix and stir at room temperature, and heat at 80°C until the solids are completely dissolved to obtain an organic amine-type copper-based ion solution;

[0042] Put 1000g of powdered polyamide into the kneader, heat at 80°C for 20min, then add 30ml of organic amine-type copper-based ion solution, mix well and heat to 160°C for kneading, after kneading for 10min, add saturated chloride 40ml of iron solution, 50g of decabromodiphenyl ether, heat to 195°C and carry out secondary mixing, the time of secondary mixing is 10min, after completion, add 15g of boric acid, stir evenly, vacuum degassing for 80min, after degassing is completed, use The extruder extrudes polyamide fiber. The temperature settings of the extruder from front to back are 220°C, 230°C, 240°C, 250°C, and 256°C. The head temperature is set at 260°C to extrude 2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com