Cylindrical lithium ion power battery shell and manufacturing method thereof

A technology of power battery and manufacturing method, applied in the manufacture of battery case and cylindrical lithium-ion power battery case, can solve the problems of battery explosion, low mechanical strength, poor thermal conductivity, etc. The effect of anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

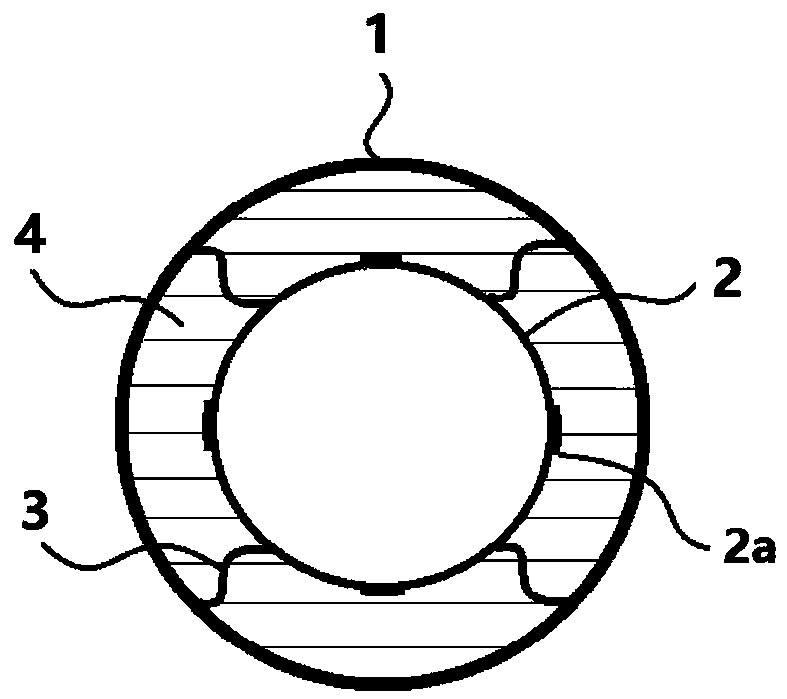

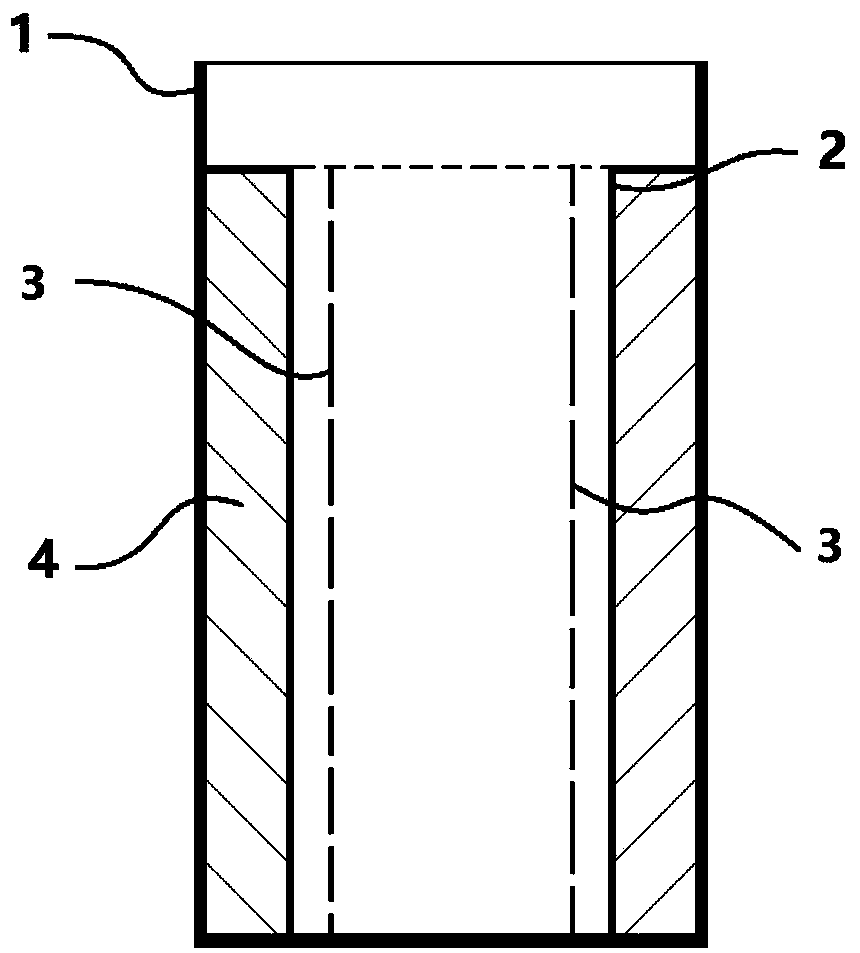

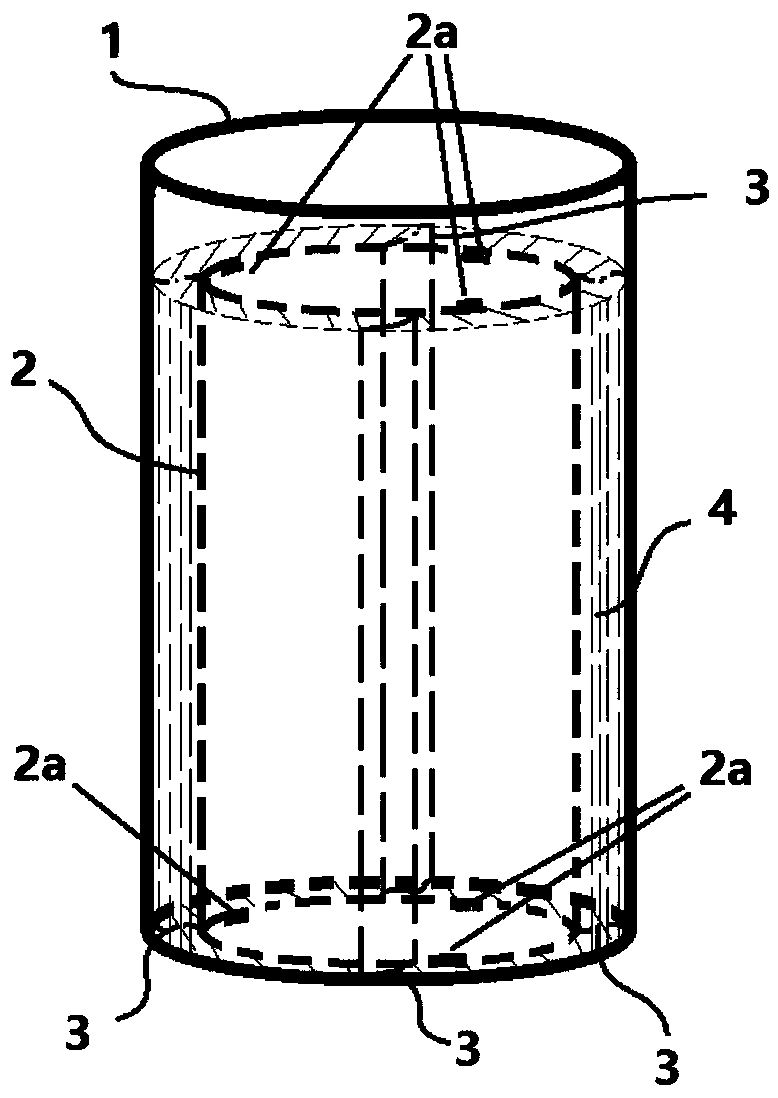

[0043] A kind of safety battery shell of cylindrical lithium-ion power battery provided by the present invention, refer to Figure 1 to Figure 5 , including the outer shell 1, the inner shell 2, the connecting part 3 of the inner and outer shells, and the foam filling layer 4 between the inner and outer shells; the bottom of the cylindrical outer shell 1 and the outer shell The bottom edge of 2 is connected by welding, the outer cylindrical outer wall of outer shell 1 is connected by welding, and the S-shaped connecting part 3 is connected with the outer cylindrical wall of inner shell 2 by welding, and the lower edge of inner shell 2 is connected with outer shell 1 The inner side of the bottom is welded and connected, and there is a light, elastic foam filling layer 4 between the inner and outer shells.

[0044] More specifically, the outer shell 1 is pressed into a cylindrical body by a metal plate with a thickness of 1-5mm, specifically including the shell wall and the shel...

Embodiment 2

[0049] A manufacturing method of a cylindrical lithium-ion power battery case provided in Example 1 includes the following steps:

[0050] Step A): pressing a stainless steel plate with a thickness of 1 mm to form a cylindrical outer shell; Step B): cutting the stainless steel with a thickness of 0.1 mm to the required size, pressing two Z-shaped folded parts with a width of 1 mm, Re-rolling / welding to make a cylindrical inner shell; step C): press a stainless steel plate with a thickness of 0.1mm and a hole with a diameter of 2.5mm to form an S-shaped connection; step D): put 2 One end of the S-shaped connection part is bonded to the outside of the inner shell with conductive glue; Step E): Weld the bottom edge of the memory case (2) to the bottom of the outer shell (1), and the other end of the S-shaped connection part Bond or weld the inner side of the outer shell with conductive adhesive; Step F): Inject the foam filling layer between the inner and outer shells to about 1-...

Embodiment 3

[0061] Another manufacturing method of a cylindrical lithium-ion power battery case provided in Example 2 includes the following steps:

[0062] Step A): pressing a stainless steel plate with a thickness of 5mm to form a cylindrical outer shell; Step B): cutting the stainless steel with a thickness of 0.5mm into the required size, pressing four Z-shaped folding parts with a width of 5mm, Then crimp / weld to make a cylindrical inner shell; step C): press a stainless steel plate with a thickness of 0.5mm and a hole diameter of 10mm to form an S-shaped connection; step D): put 4 S One end of the S-shaped connection part is glued or welded to the outside of the inner shell; Step E): Weld the bottom edge of the memory shell to the bottom of the outer shell, and the other end of the S-shaped connection part is glued with conductive glue Or welded on the inner side of the outer shell; Step F): Inject the foam filling layer between the inner and outer shells to about 1-3mm higher than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com