Method for improving unfavorable board manufacturing at fusing place

A bad and board-making technology, which is applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problems of easy delamination, board explosion or surface copper skin blistering, etc., to improve the poor board making of the fusion position , avoid foaming, enhance the binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

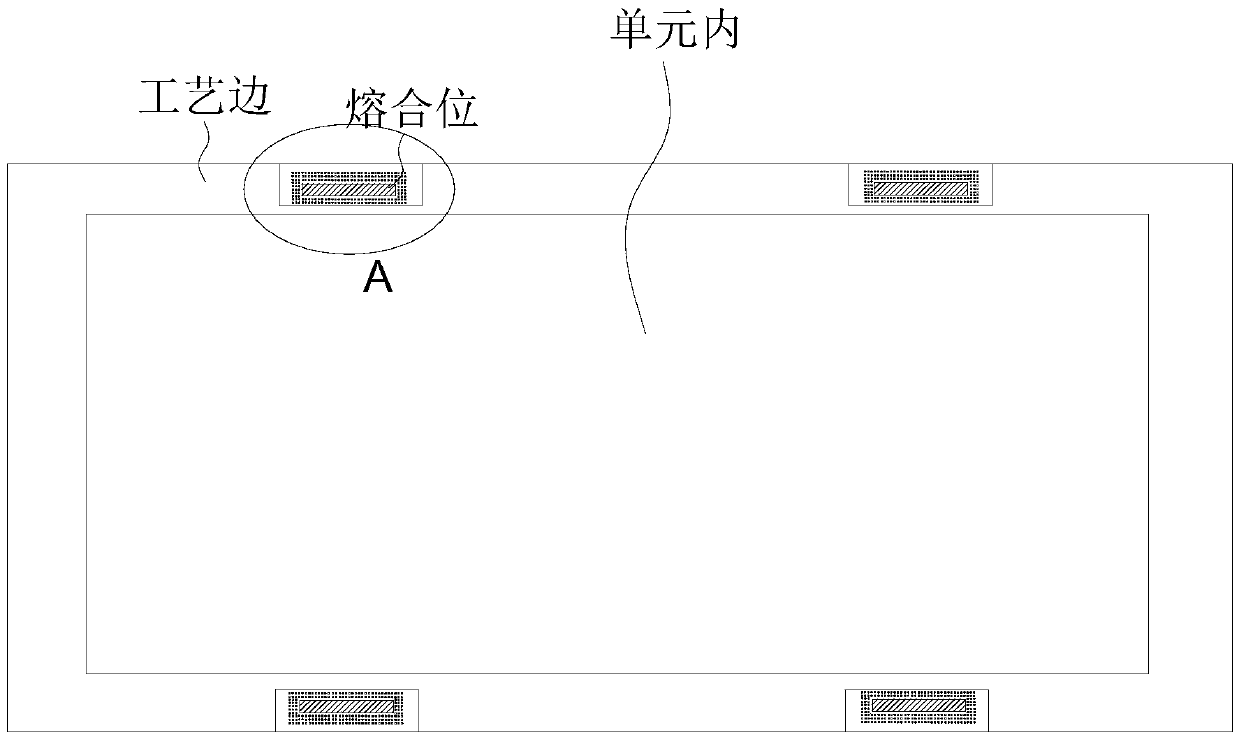

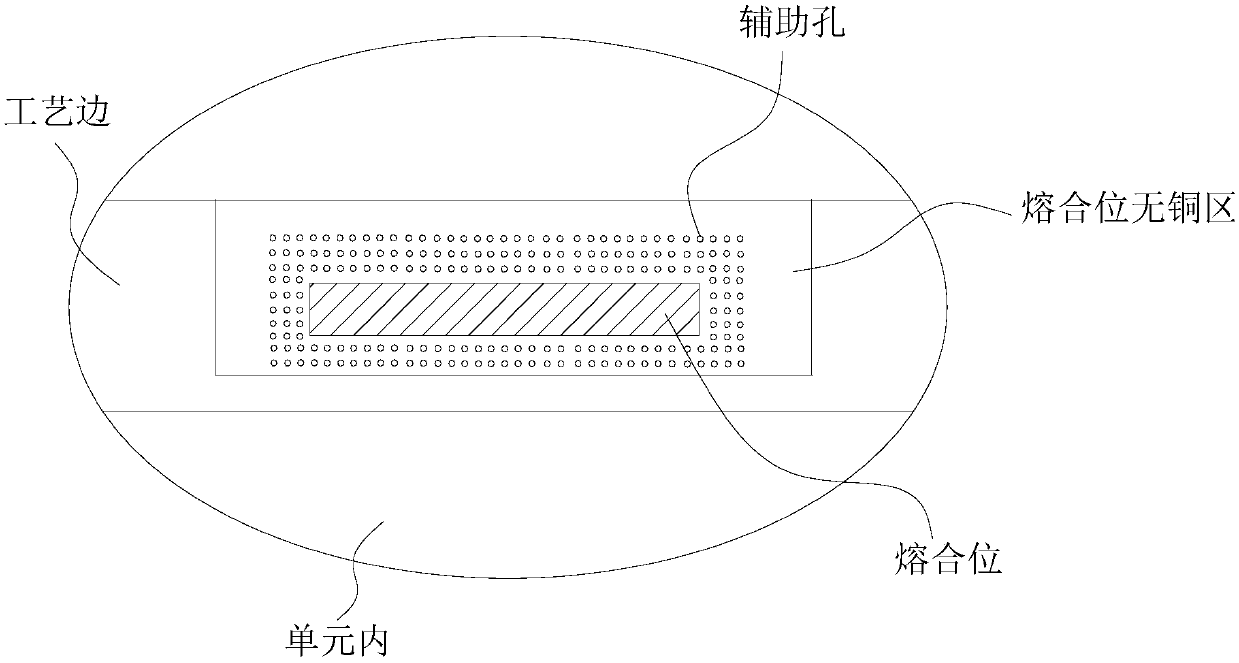

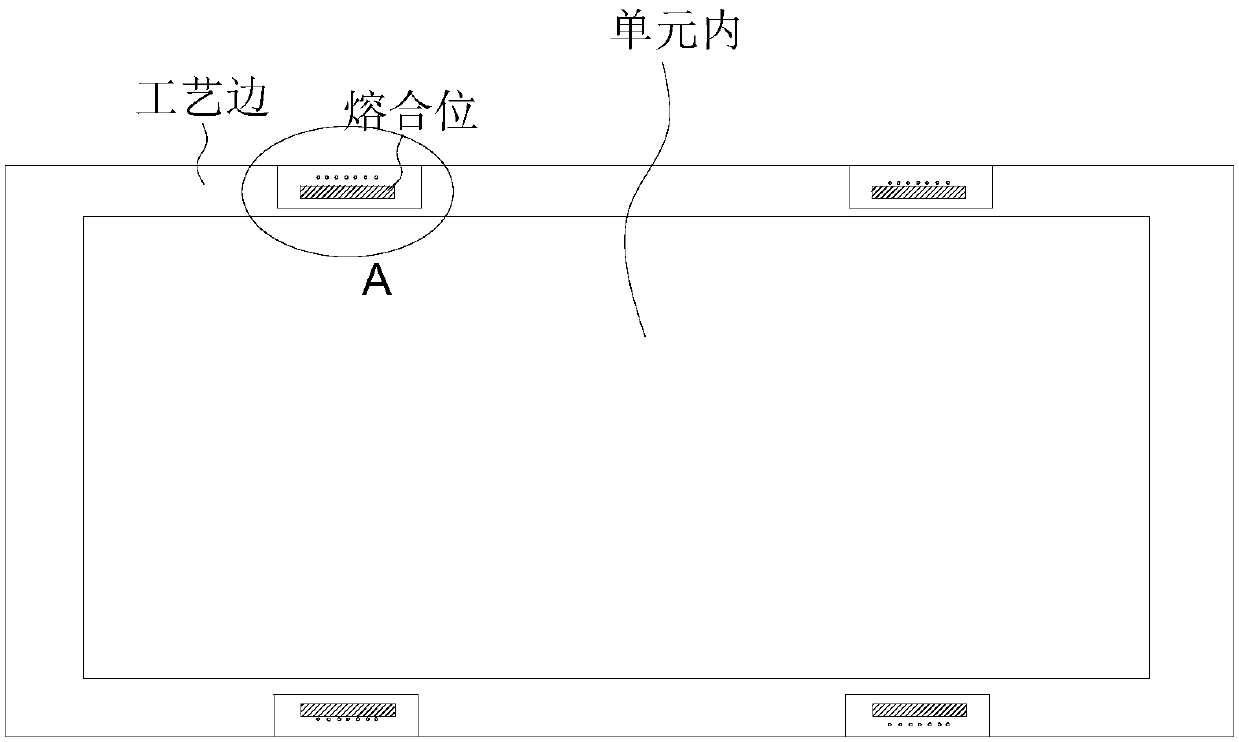

[0027] This embodiment provides a method for making a rigid-flex board, and in particular provides a method for pre-fixing fusion with fusion technology in the pressing process to improve poor board production due to delamination and explosion at the fusion site.

[0028] (1) Cutting: According to the size of the panel required by the design, the core board of the soft board and the core board of the hard board are cut out. The outer periphery of the soft board core board and the hard board core board is the process edge, and the width of the process edge is 25mm.

[0029] (2) Inner layer circuit production (negative film process): Inner layer graphic transfer, use a vertical coating machine to coat photosensitive film, the thickness of the photosensitive film is controlled to 8 μm, use a fully automatic exposure machine, and use a 5-6 grid exposure ruler (21 grid exposure ruler) to complete the exposure of the inner layer circuit; inner layer etching, etch the inner layer cir...

Embodiment 2

[0056] This embodiment provides a method for manufacturing a PCB, and in particular provides a method for pre-fixing fusion with fusion technology in the lamination process to improve poor board production caused by delamination and explosion at the fusion position.

[0057] (1) Cutting: cut out the inner core board according to the panel size required by the design.

[0058] (2) Make the inner layer circuit: adopt the negative process to make the inner layer circuit on the inner layer core board to obtain the inner layer circuit board. After the inner layer circuit is etched on the inner core board, POE punching and inner layer AOI are performed sequentially according to the conventional procedures.

[0059] (3) Lamination: pre-stack the inner core board, prepreg PP, and outer copper foil, and perform fusion pre-fixation by fusion, and pre-fix each layer to form a pre-stacked structure. Then select appropriate lamination conditions according to the Tg of the sheet to press t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com