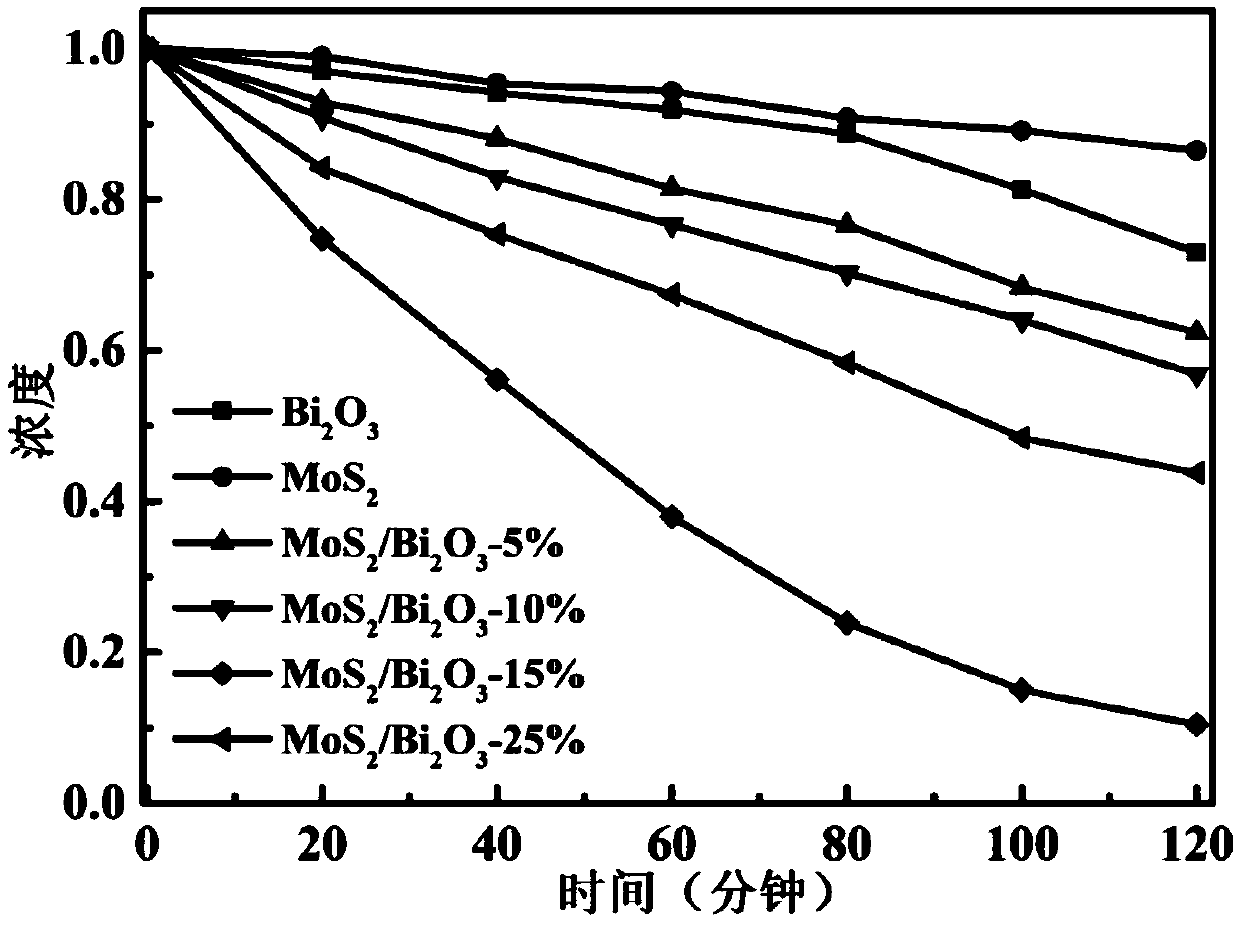

Preparation method of MoS2/Bi2O3 p-n heterojunction photocatalyst and application thereof

A bi2o3p-n, photocatalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instrument and method, etc., to achieve the effect of improving efficiency, improving photocatalytic activity, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

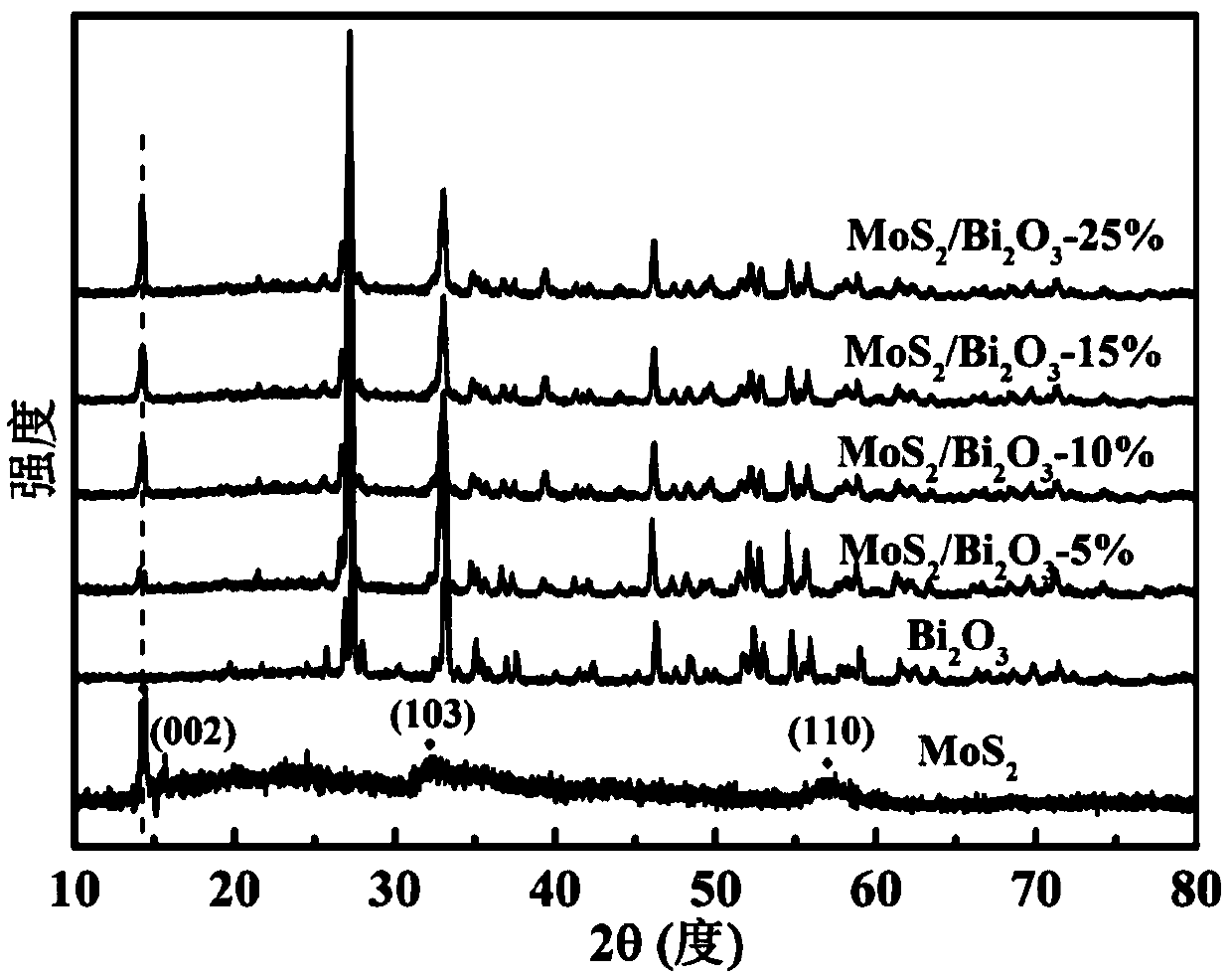

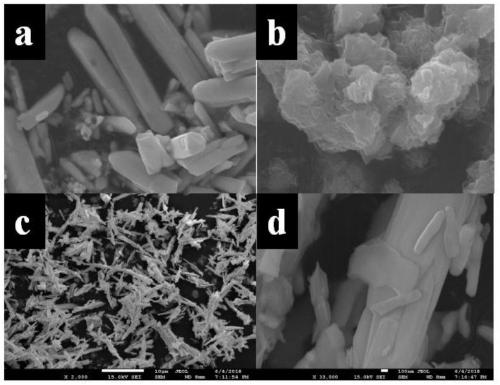

[0036] (1)MoS 2 Preparation: 1.00g sodium molybdate dihydrate (Na 2 MoS 2 2H 2 O) and 1.30g thiourea (CS(NH 2 ) 2 ) was dissolved in 60mL of deionized water and stirred until clarified, the resulting mixed liquid was transferred to a 100mL stainless steel autoclave, sealed and reacted at 180°C for 24h, then cooled to room temperature; the obtained product was collected by centrifugation and washed with absolute ethanol and Wash with deionized water three times, and then dry at 60°C for 12 hours to obtain MoS 2 ;

[0037] (2) Bi 2 o 3 Preparation: 5g of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 100mL of deionized water, stirred for 30min, adjusted to pH 8 with 10Mol / L NaOH solution, ultrasonicated for 30min, then stirred for 18h to obtain a precipitate, which was collected by centrifugation and washed with absolute ethanol and deionized water respectively. After washing 3 times, dry at 60 °C for 12 h, and finally the bright yellow precipitate was calcined in air at 400 °C...

Embodiment 2

[0040] (1)MoS 2 Preparation: 1.10g sodium molybdate dihydrate (Na 2 MoS 2 2H 2 O) and 1.40g thiourea (CS(NH 2 ) 2 ) was dissolved in 60mL of deionized water and stirred until clarified, the resulting mixed liquid was transferred to a 100mL stainless steel autoclave, sealed and reacted at 180°C for 24h, then cooled to room temperature; the obtained product was collected by centrifugation and washed with absolute ethanol and Wash with deionized water 3 times, and then dry at 60°C for 12 hours;

[0041] (2) Bi 2 o 3 Preparation: 5g of Bi(NO 3 ) 3 ·5H 2 Dissolve O in 100mL deionized water, stir for 30min, adjust the pH value to 9 with 10Mol / L NaOH solution, then sonicate for 30min, then stir for 20h to obtain a precipitate, which is collected by centrifugation and washed with absolute ethanol and deionized water After 3 times, it was dried at 60°C for 12h, and finally the bright yellow precipitate was calcined in air at 400°C for 2h to obtain Bi 2 o 3 ;

[0042] (3)Mo...

Embodiment 3

[0044] (1)MoS 2 Preparation: 1.20g sodium molybdate dihydrate (Na 2 MoS 2 2H 2 O) and 1.60g thiourea (CS(NH 2 ) 2 ) was dissolved in 60mL of deionized water and stirred until clarified, the resulting mixed liquid was transferred to a 100mL stainless steel autoclave, sealed and reacted at 180°C for 24h, then cooled to room temperature; the obtained product was collected by centrifugation and washed with absolute ethanol and Wash with deionized water 3 times, and then dry at 60°C for 12 hours;

[0045] (2) Bi 2 o 3 Preparation: 5g of Bi(NO 3 ) 3 ·5H 2 Dissolve O in 100mL of deionized water, stir for 30min, adjust the pH value to 10-11 with 10Mol / L NaOH solution, ultrasonicate for 30min, then stir for 24h to obtain a precipitate, collect the precipitate by centrifugation and wash with absolute ethanol and deionized water After each wash 3 times, dry at 60°C for 12h, and finally air calcinate the bright yellow precipitate at 400°C for 2h to obtain Bi 2 o 3 ;

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com