Processing method of deep blind hole

A processing method, deep blind hole technology, applied in the direction of the boring bar, etc., can solve the problems that the bottom of the hole cannot achieve the anti-vibration effect, delay the production process, and cannot process, etc., achieve a good anti-vibration knife effect, reduce the phenomenon of knife vibration, and save machining cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

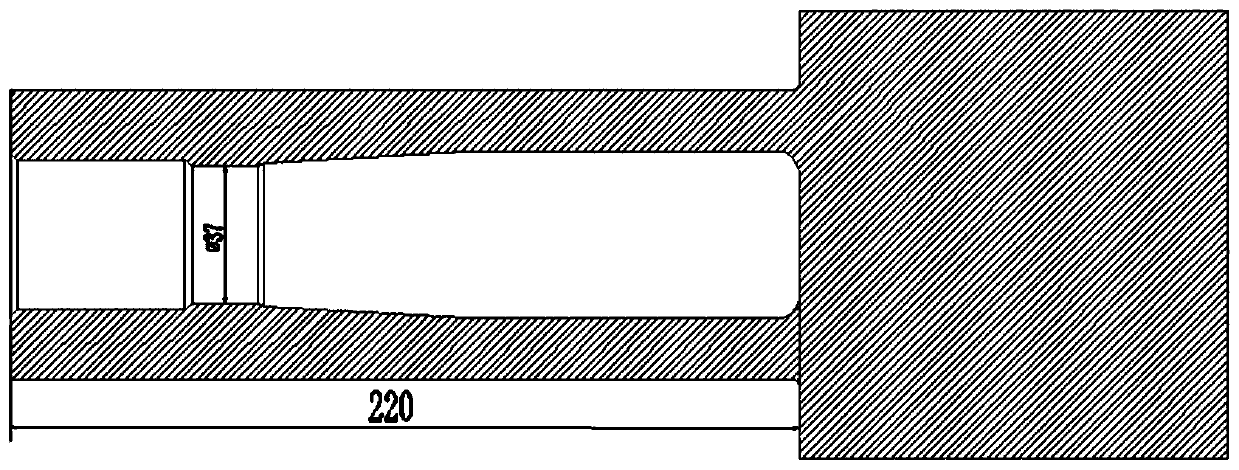

[0025] This embodiment discloses a method for processing a titanium alloy deep blind hole with a depth of 220mm and a diameter of φ37, which includes the following steps:

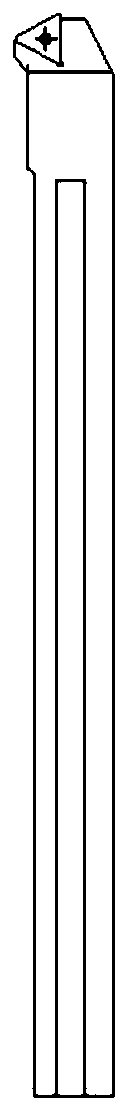

[0026] S1. Tool selection: Choose an over-center toolholder and a shock-proof toolholder as processing tools, wherein the outside diameter of the toolholder of the over-center toolholder is greater than half of the hole diameter of the hole to be processed, and the tool tip is located on the tool The shaft is within the outer circle and is close to the center of the shank, so it can be processed through the center; the shock-proof shank is an ordinary shock-proof shank whose outer diameter is larger than half of the hole to be processed.

[0027] S2. Punching: Determine the position of the hole to be punched on the workpiece, use the U drill to punch the hole at the predetermined position, and then use the rough boring tool for rough boring, reserve 3mm machining allowance at the bottom of the hole, and reserve 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com