Advanced dephosphorization treatment system and process for sewage

A sewage treatment system and sewage treatment method technology, applied in water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of clogging and loss of treatment capacity, long construction period, low treatment load, etc. problem, to achieve the effect of short debugging period, low operating cost and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

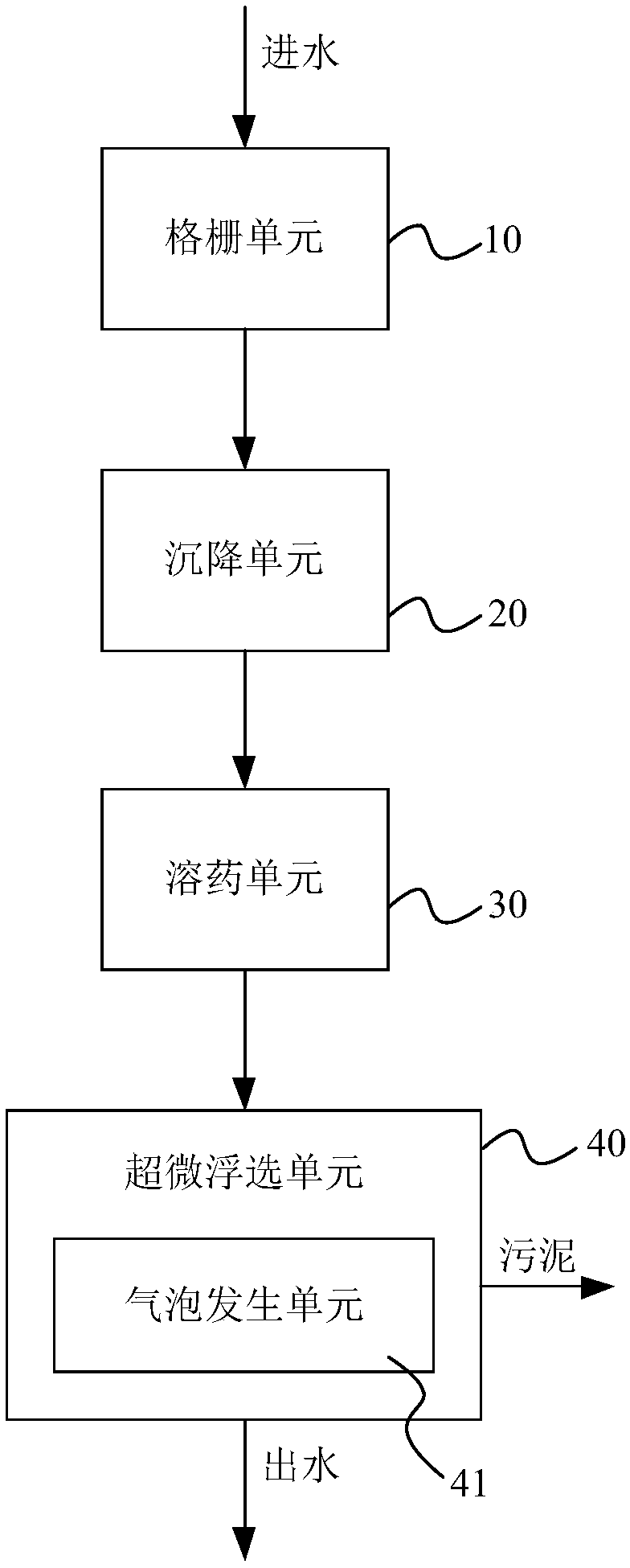

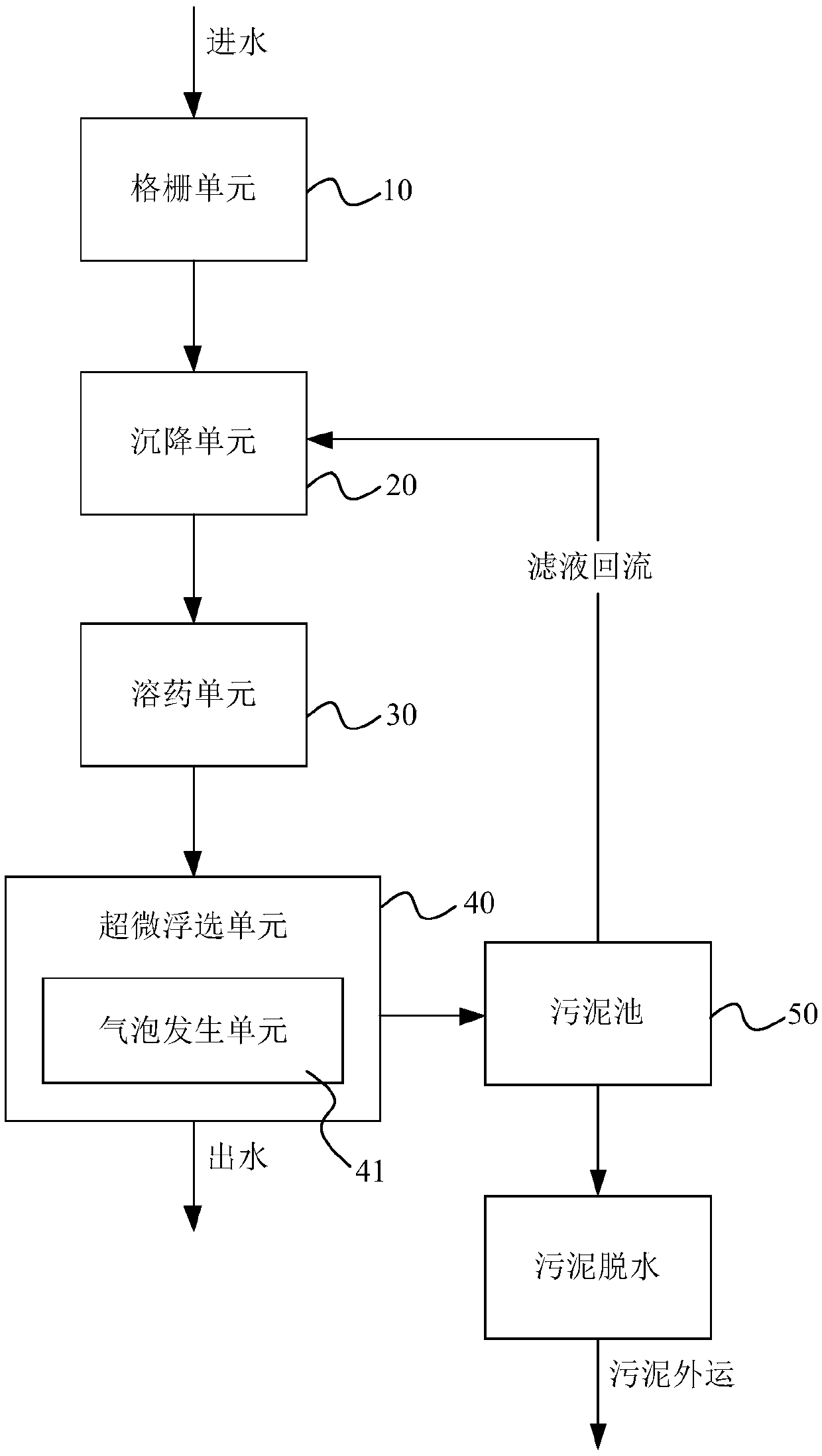

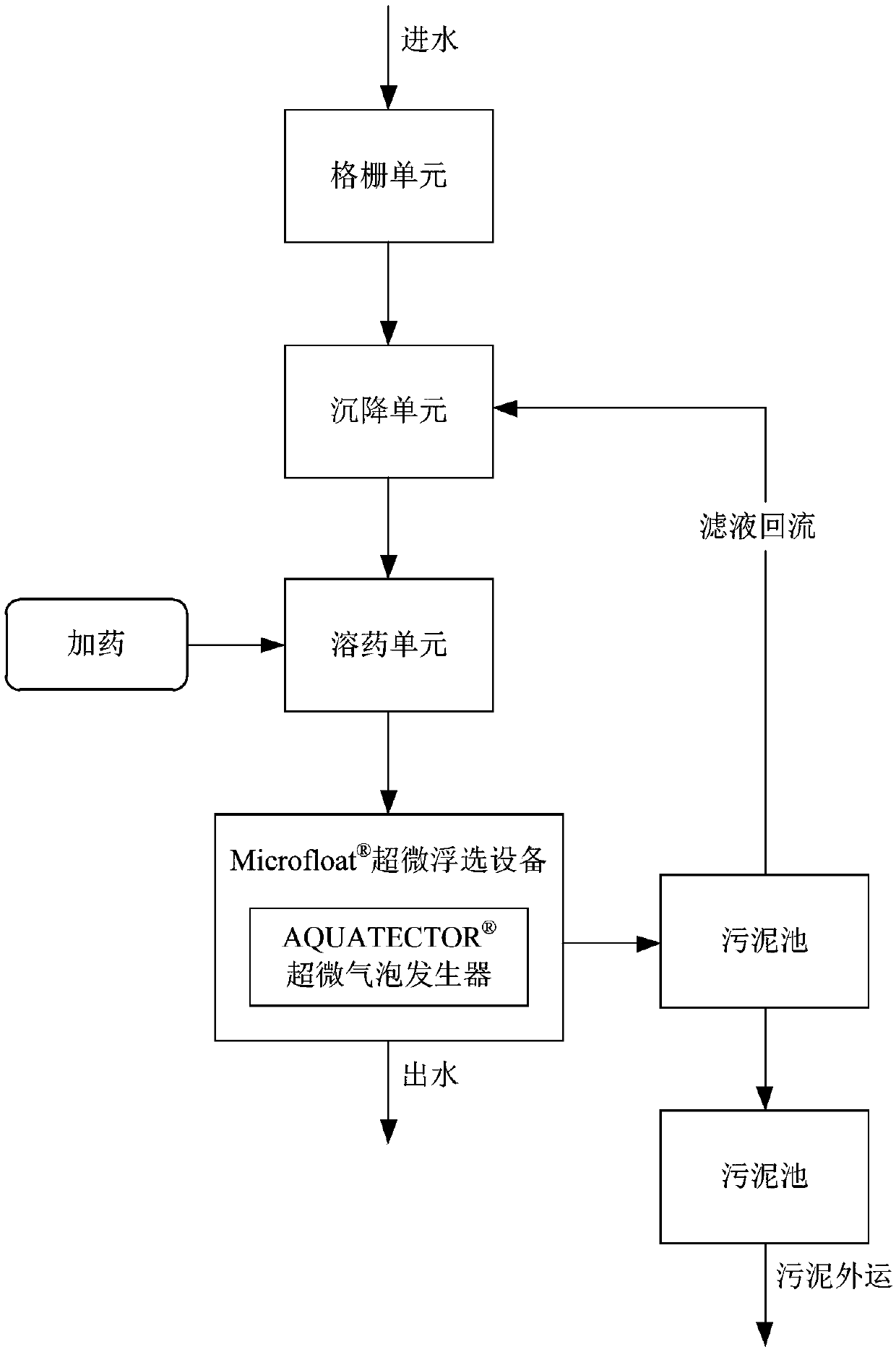

[0053] Sewage treatment system process such as image 3 shown. The sewage treatment system includes: grille unit, sedimentation unit, drug dissolving unit and Ultrafine flotation equipment. The ultrafine flotation equipment is equipped with Micro bubble generator. Each unit in the system passes through Remote operation and maintenance system for integrated automation control.

[0054] The pipeline layout in the sewage treatment system is as follows: Figure 4 shown. Figure 4 Among them, the direction of the arrow on the pipeline is the flow direction of the medium, 1 is the sludge feed pipe (DN65), 2 is the water pipe (DN20), 3 is the dosing pipe (DN25), 4 is the filtrate discharge pipe (DN80), and 5 is the Clean water pipe (DN20) after treatment, 6 is electric wire. 11 for Ultrafine flotation equipment, 12 is the sludge tank, 13 is the screw pump, 14 is the self-priming pump, 15 is the power distribution room, 16 is the dosing room, 17 is the metering pump, 18 ...

Embodiment 2

[0092] The sewage treatment system of Example 1 is applied to an emergency treatment project of urban domestic sewage in a certain place.

[0093] Basic information of the project

[0094]

[0095]

[0096] Equipment occupies

[0097] Ultrafine flotation equipment covers an area of about 70m 2 , the project covers an area of 150m 2 (occupancy is very small, the equipment is easy to operate)

[0098] System matching

[0099] Remote operation and maintenance system (implementing remote monitoring and control, data mutual transmission), the site does not need to stick to it all the time, reducing the workload and further reducing equipment man-made failures.

[0100] water quality information

[0101]

[0102] Note: The values outside the brackets are the control indicators when the water temperature is >12°C, and the values in the brackets are the control indicators when the water temperature is ≤12°C. In the above table, COD is chemical oxygen demand,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap