Rust remover suitable for metal material surface and rust removal technology thereof

A technology of metal material and rust remover, applied in the field of machinery, can solve the problems of large consumption of acid solution, decline of metal mechanical properties, influence of steel strength, etc., and achieve the effects of simple process parameters, less environmental pollution, and strong rust removal ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

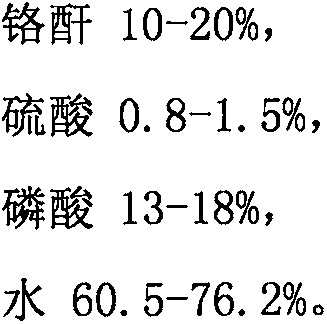

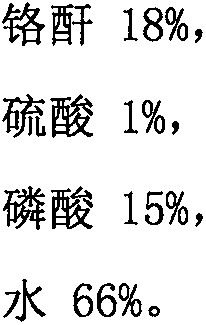

[0027] A kind of derusting agent suitable for metal material surface is made up of the raw material of following mass percentage:

[0028] Chromic anhydride 18%,

[0029] Sulfuric acid 1%,

[0030] Phosphoric acid 15%,

[0031] Water 66%.

[0032] A kind of derusting process suitable for steel precision parts, comprises the steps:

[0033] (1) Degrease the parts with acetone;

[0034] (2) Soak the parts after degreasing in step (1) in the derusting solution, and heat to 80°C for 10 minutes;

[0035] (3) Rinse the parts with tap water for 3 minutes;

[0036] (4) The parts are immersed in 0.6% sodium carbonate aqueous solution for 7 minutes;

[0037] (5) Immerse the parts in the passivation solution and heat to 80°C for 10 minutes;

[0038] (6) Rinse with tap water, wipe dry, and seal with oil.

[0039] In this embodiment, the components of the passivation solution in the step (5) are 50% of 10% sodium nitrite aqueous solution and 50% of 0.5% sodium carbonate aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com