A kind of excavation construction method of large cross-section soft rock tunnel

A construction method and large-section technology, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of untimely support of section surrounding rock, poor rock stability, and difficult rock excavation, etc., achieving remarkable economic benefits, The effect of reducing equipment wear and compact process connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be further described below in conjunction with the embodiments in the drawings.

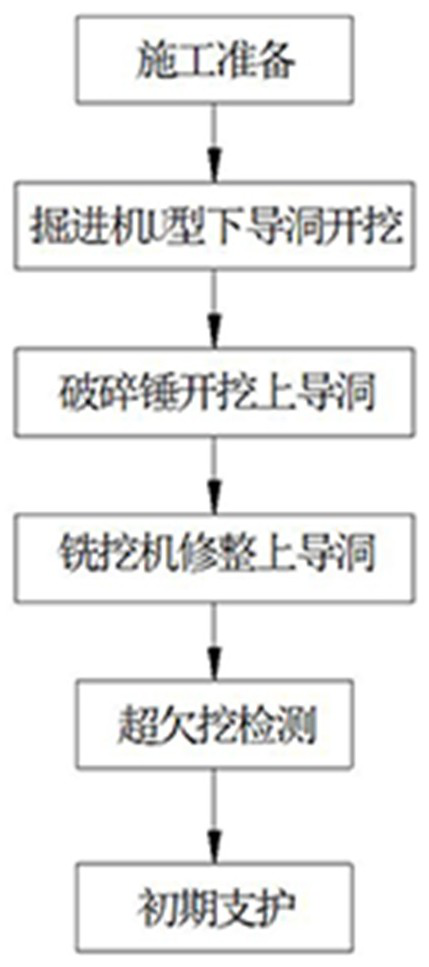

[0026]Such asfigure 1 withfigure 2As shown, the tunnel excavation construction method includes the following steps:

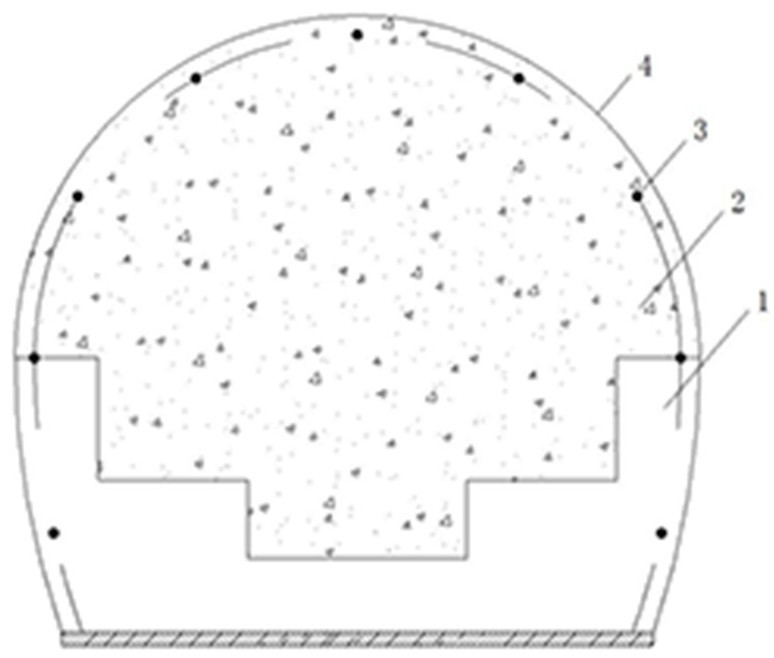

[0027]Step 1: The tunnel is a soft rock tunnel with surrounding rocks of category IV and V. At the beginning of excavation, a circular laser pointer is installed on the wall of the tunnel that has been initially lined 20 meters away from the excavation face, and projected on the tunnel section Laser reference point 3 provides a reference point for excavation of the working face. The laser pointer is arranged around the wall of the hole which is initially lined behind the tunnel face, and projects a plurality of laser reference points 3 along the direction of the contour line 4 of the section.

[0028]Step 2: Use a cantilever roadheader to excavate the U-shaped lower pilot tunnel 1 in the rock layer under the tunnel section. For example, a horseshoe-shaped tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com