Efficient split type diesel engine clustered cooling system and application method thereof

A cooling system and oil cooling system technology, applied in liquid cooling, engine cooling, coolant flow control, etc., can solve problems such as not meeting the needs of large-scale industrial production, unable to use large diesel engine clusters, etc., and achieve excellent cooling effect. , Conducive to neat layout, moderate temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

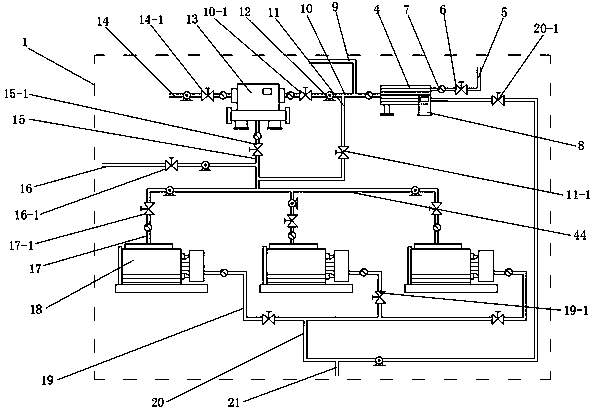

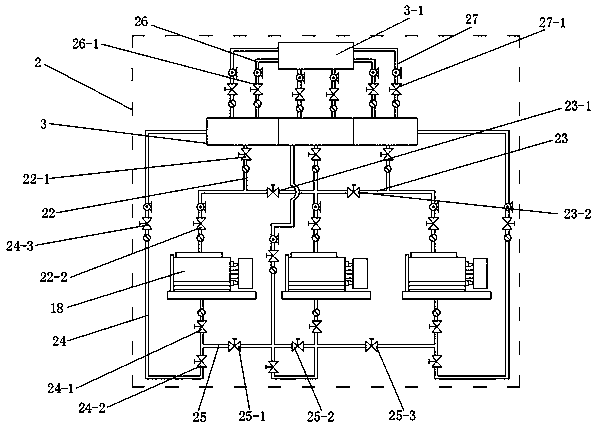

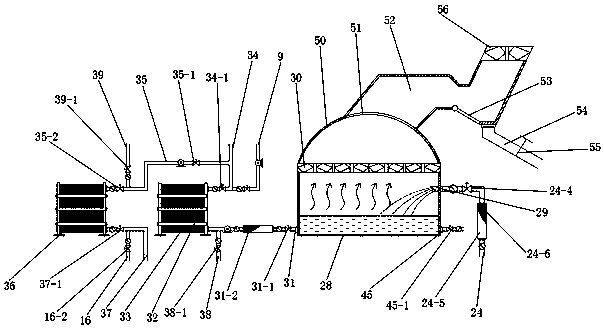

Embodiment 1

[0034] As shown in the accompanying drawings of the description, an efficient split-type diesel engine cluster cooling system includes a water cooling system 1, an oil cooling system 2, a single air-cooled supercharged diesel engine 18 and a control system; the water cooling system 1 mainly includes a water treatment unit 4 and chilled water unit 13; the inlet of the water treatment unit 4 is connected to a raw water pipeline 5, and the outlet is connected to a pure water outlet pipeline 10; the pure water outlet pipeline 10 is divided into a pure water branch pipe I9 and a pure water branch pipe II11; The pure water outlet pipeline 10 is connected to the ice water unit 13; the outlet of the ice water unit 13 is connected with the ice water outlet pipeline 15, and the water return port is connected with the ice water return pipeline 14; the ice water outlet pipeline 15 separates the ice Water branch pipe 16; the end of the pure water branch pipe II11 connected to the ice water ...

Embodiment 2

[0043] The structure and principle of this embodiment 2 are basically the same as that of embodiment 1, the difference is that the entrance of the heat dissipation box 28 is located on the upper part of the box wall, and is provided with a fuel injection port 29 with a "V" opening; the fuel injection port 29 is connected to Oil return pipe 24. High-temperature machine oil flows into the cooling box 28 from the single-air-cooled supercharged diesel engine 18, and is sprayed out through the fuel injection port 29, and the fuel injection port 29 of the "V" word opening plays the effect of expanding spraying.

Embodiment 3

[0045] The structure and principle of this embodiment 3 are basically the same as that of the embodiment 1, except that the two sides of the bottom of the cooling box 28 are respectively connected with a bottom oil outlet pipe 31 and an oil passage pipe 45 at the bottom of the case; the oil passage pipe 45 is provided with a proportional valve XXIX45 -1. When cleaning or maintenance is required, the oil pipe 45 is used to discharge the engine oil in the cooling box 28 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com