Draining pump with impeller of small hub ratio

A wheel-to-hub ratio and drainage pump technology, which is applied to parts, pumps, and pump devices of elastic fluid pumping devices, can solve problems such as poor flow capacity of impellers, corrosion of water-passing wall surfaces, rough surfaces, etc., and achieve increased Large flow channel cross-sectional area, improved flow capacity, and excellent hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

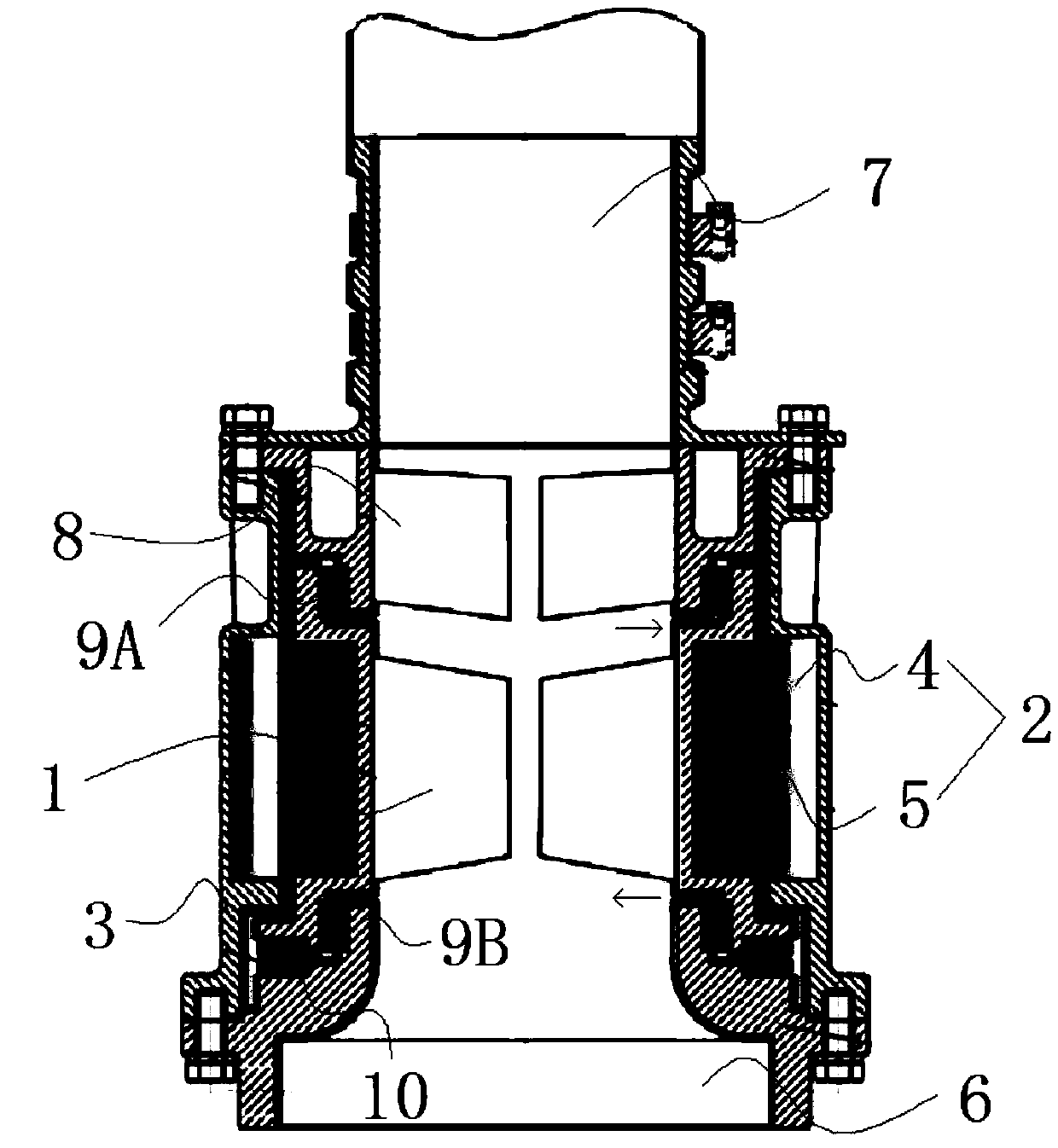

[0073] like figure 1 As shown, a drainage pump with a small wheel-to-hub ratio impeller includes an impeller 1 and a driving part 2 that drives the rotation of the impeller 1. The impeller 1 is a small wheel-to-hub ratio impeller. The drainage pump also includes a housing 3. The drive The part 2 includes a stator assembly 4 fixed on the housing 3, the driving part 2 also includes a rotor assembly 5 cooperating with the stator assembly 4, the rim of the impeller with a small hub ratio is fixedly connected to the inner wall of the rotor assembly 4, And following the rotation of the rotor assembly 4, the small hub is hollow than the middle part of the impeller.

Embodiment 2

[0075] like figure 1 As shown, on the basis of Embodiment 1, the two sides of the housing 3 are respectively provided with a water inlet 6 and a water outlet 7, and the two ends of the rotor assembly 5 are respectively connected with the water inlet 6 and the water outlet 7. The nozzle 7 is provided with a guide vane 8 matching with the impeller 1, and the water passing walls of the casing 3, the rotor assembly 5, and the stator assembly 4 are all provided with anti-corrosion linings using fluorine-lined technology.

Embodiment 3

[0077] like figure 1 As shown, on the basis of Example 2, the rotor assembly 5 is seated in the stator assembly 4 through the wear ring 10, and the upper and lower sides of the rotor assembly 5 are respectively provided with the rotor assembly 5 and the water outlet 7 The outlet-side sliding bearing 9A that cooperates with the rotation and the inlet-side sliding bearing 9B that is convenient for the rotor assembly 5 and the water inlet 6 to rotate in cooperation, the rotor assembly 5, the water outlet 7, the stator assembly 4 and the water inlet 6 are used for The cooling channels for cooling and lubrication are provided with anti-corrosion linings using fluorine-lined technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com