Quilt capable of improving softness as well as production process thereof

A production process and softness technology, applied in the field of quilt and its production process, can solve the problems of reducing the resilience and bulkiness of the quilt, affecting the warmth and service life, and being uncomfortable when covering the body, so as to achieve softness and softness. Excellent and elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

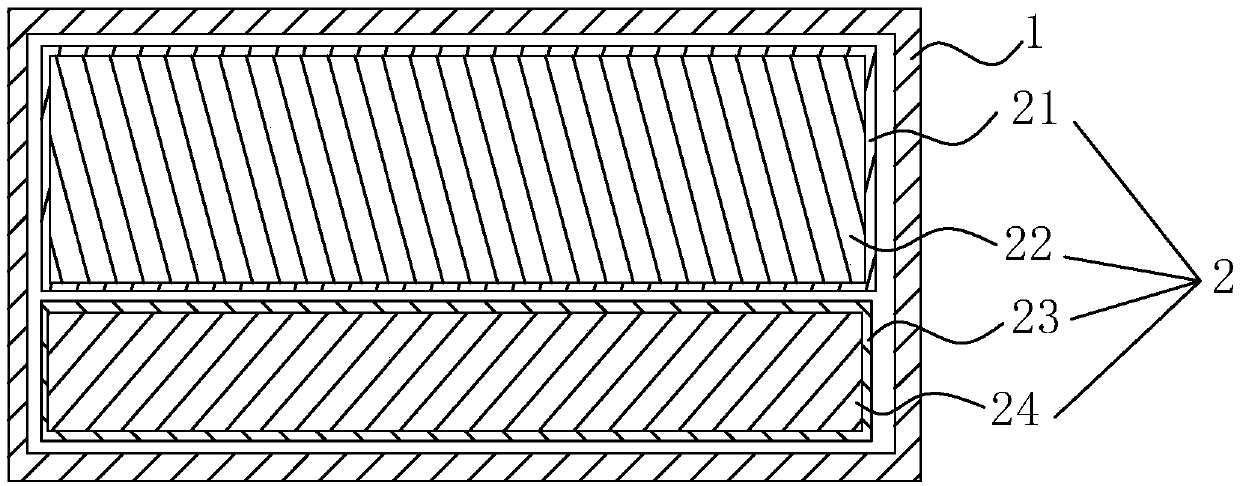

Image

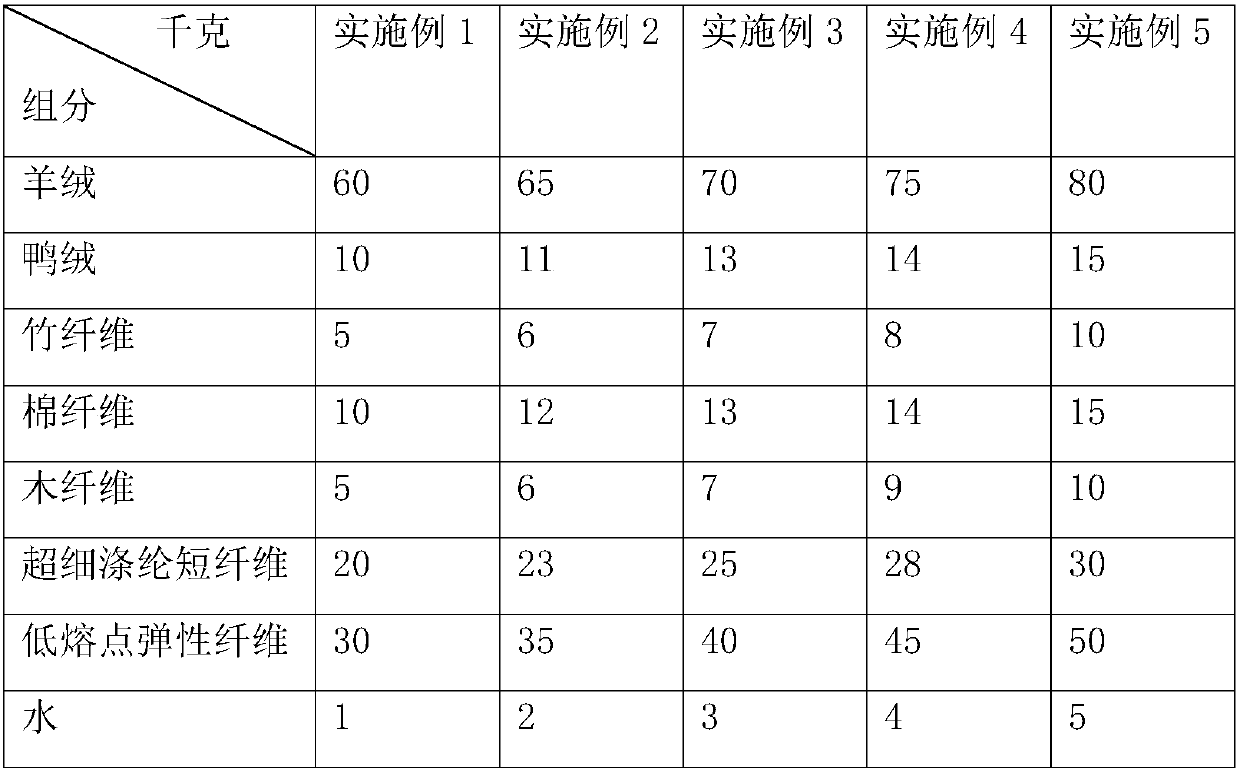

Examples

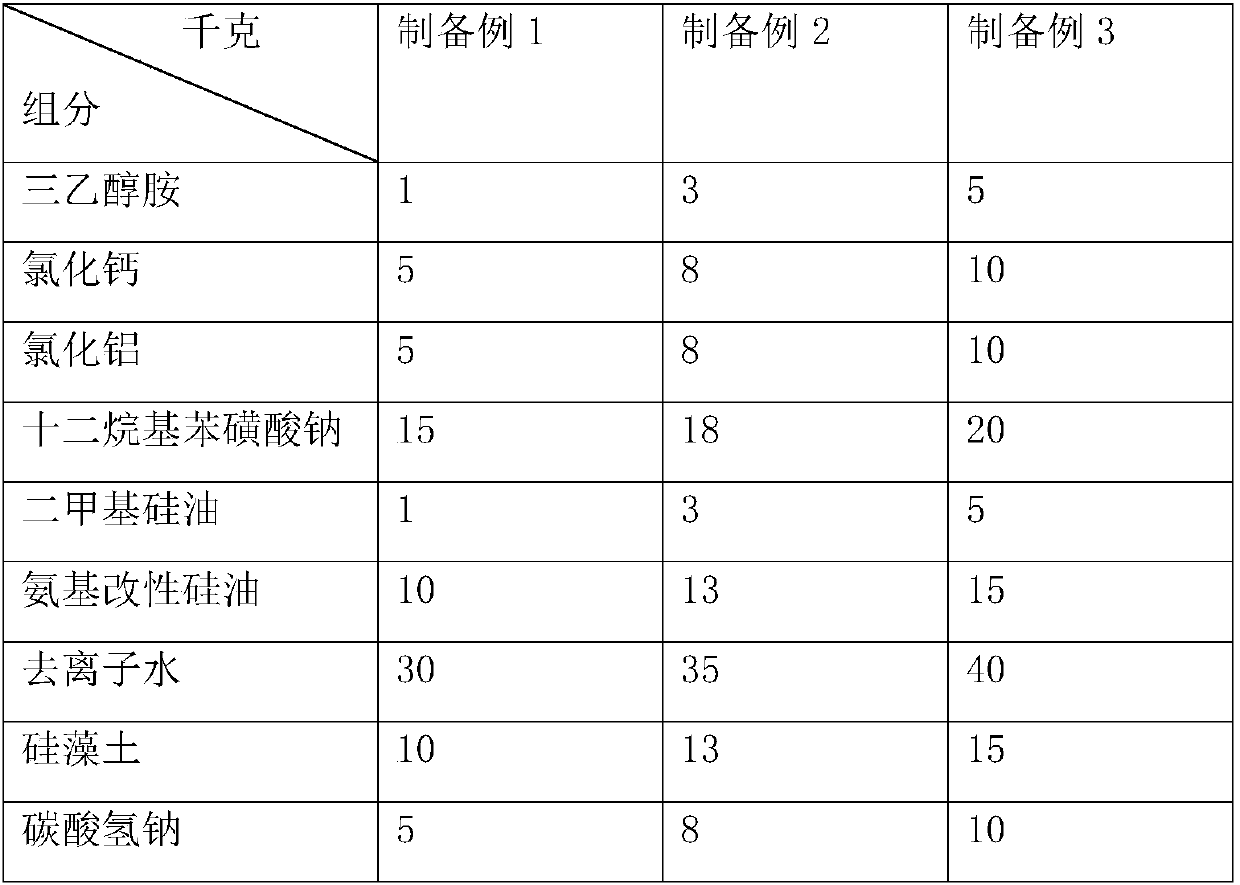

preparation example 1-3

[0045] In Preparation Example 1-3, triethanolamine, calcium sulfide, aluminum chloride, sodium bicarbonate, and sodium dodecylbenzenesulfonate are all analytically pure, and the simethicone oil is selected from PMX- 200 type dimethyl silicone oil, amino-modified silicone oil is selected from Goon1202 type amino-modified silicone oil sold by Dongguan Jiahong Organic Silicon Technology Co., Ltd., diatomaceous earth is selected from the model 400 sold by Lingshou County Shunkai Mineral Products Processing Factory diatomite.

[0046] Preparation Example 1: According to the ratio in Table 1, 1 kg of triethanolamine, 5 kg of calcium chloride and 5 kg of aluminum chloride were ultrasonically dispersed for 10 minutes, the ultrasonic power was 1200 W, the temperature was raised to 70 ° C, and 15 kg of dodecylbenzene was added thereto Sodium sulfonate, 1kg simethicone oil, 10kg amino-modified silicone oil and 30kg deionized water, stirred at 500r / min for 20min, cooled to 40°C, added 10k...

preparation example 2

[0049] Preparation Example 2: According to the ratio in Table 1, 3 kg of triethanolamine, 8 kg of calcium chloride and 8 kg of aluminum chloride were ultrasonically dispersed for 15 minutes, the ultrasonic power was 1350 W, the temperature was raised to 75 ° C, and 18 kg of dodecylbenzene was added thereto Sodium sulfonate, 3kg dimethyl silicone oil, 13kg amino-modified silicone oil and 33kg deionized water, stirred at 750r / min for 25min, cooled to 45°C, added 13kg of diatomaceous earth and 8kg of sodium bicarbonate, at 750r / min Stir for 1.5h, and cool down to 25°C while stirring.

preparation example 3

[0050] Preparation Example 3: According to the ratio in Table 1, 5 kg of triethanolamine, 10 kg of calcium chloride and 10 kg of aluminum chloride were ultrasonically dispersed for 20 minutes, the ultrasonic power was 1500 W, the temperature was raised to 80 ° C, and 20 kg of dodecylbenzene was added thereto Sodium sulfonate, 5kg simethicone oil, 15kg amino-modified silicone oil and 40kg deionized water, stirred at 1000r / min for 30min, cooled to 50°C, added 15kg diatomaceous earth and 10kg sodium bicarbonate, at 1000r / min Stir for 2h, and cool down to 30°C while stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com