Intelligent application program and optimization method for Fenton oxidation technology

An optimization method and application program technology, applied in chemical instruments and methods, design optimization/simulation, oxidized water/sewage treatment, etc., can solve the problems of heavy screening workload and low efficiency, achieve low cost of chemicals, improve treatment Efficiency and the effect of saving test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

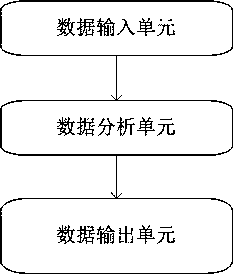

Method used

Image

Examples

Embodiment 1

[0043] In a chemical wastewater treatment project, the initial COD content is 2000-3000mg / L, and the expected removal rate of COD is 80-85%, so the optimal dosing amount obtained through the intelligent application of Fenton oxidation technology is FeSO 4 .7H 2 O 10-12g / L, in actual engineering application, the COD of Fenton effluent is 400-600 mg / L, and the wastewater treatment cost is 9-11 yuan / t wastewater. The project can quickly estimate the treatment effect and cost through the Fenton dosing calculation program, and respond quickly to market demand within one day, greatly saving test time and unnecessary repetitive work, and improving customer satisfaction.

Embodiment 2

[0045] In a concentrated brine pretreatment project, the initial COD content is 500-600mg / L, and the expected removal rate of COD is 85-90%, so the optimal dosing amount of FeSO can be obtained through the intelligent application of Fenton oxidation technology 4 .7H 2 O is 2.0-2.6g / L. In practical engineering applications, the COD of Fenton effluent is lower than 50mg / L, and the cost of wastewater treatment is 10-11 yuan / t of wastewater. In this project, based on the proficient use of Fenton technology, within two weeks after the start of the experiment, the COD of the concentrated brine was reduced to below 50mg / L, the mud content in the effluent was very small, and the cost of the agent was only 7-9 yuan / t waste water, the color of the effluent is very low, which quickly and effectively solves the problem that organic matter in concentrated brine is difficult to degrade. Therefore, the Fenton rapid sedimentation technology shortens the Fenton reaction time in the laborator...

Embodiment 3

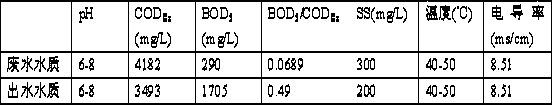

[0047] This method is used to screen and optimize the dosage of electricity-Fenton in the treatment of caprolactam production wastewater. The water quality of known caprolactam production wastewater is shown in Table 1, and the BOD of wastewater 5 / COD cr The ratio is 0.07, and the biodegradability is very poor. Adopt the present invention according to waste water COD cr content, deduced H 2 o 2 The best dosage is 1500-2000mg / L, H 2 o 2 :Fe 2+ The molar ratio is 10, 28%H 2 o 2 The dilution factor is 1, pure H 2 o 2 The ratio (K1) of COD / COD concentration is 0.5. Suitable for single-stage processing methods.

[0048] Table 1. Wastewater and product water quality of oximation unit

[0049]

[0050] It can be seen from Table 2 that after electro-Fenton treatment, the BOD of caprolactam wastewater 5 / COD cr From 0.07 to 0.49, the biodegradability of wastewater was significantly improved, COD cr The removal rate was 34%. Electro-Fenton effluent is suitable for b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com