A method for accelerating the cultivation of aerobic granular sludge based on the method of increasing the concentration of nacl

An aerobic granular sludge, increasing concentration technology, applied in the direction of using microorganisms, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of temperature control, high cost, difficult large-scale engineering application, etc. , to achieve the effects of easy aggregation, increased hydrophobicity, and reduced repulsion barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

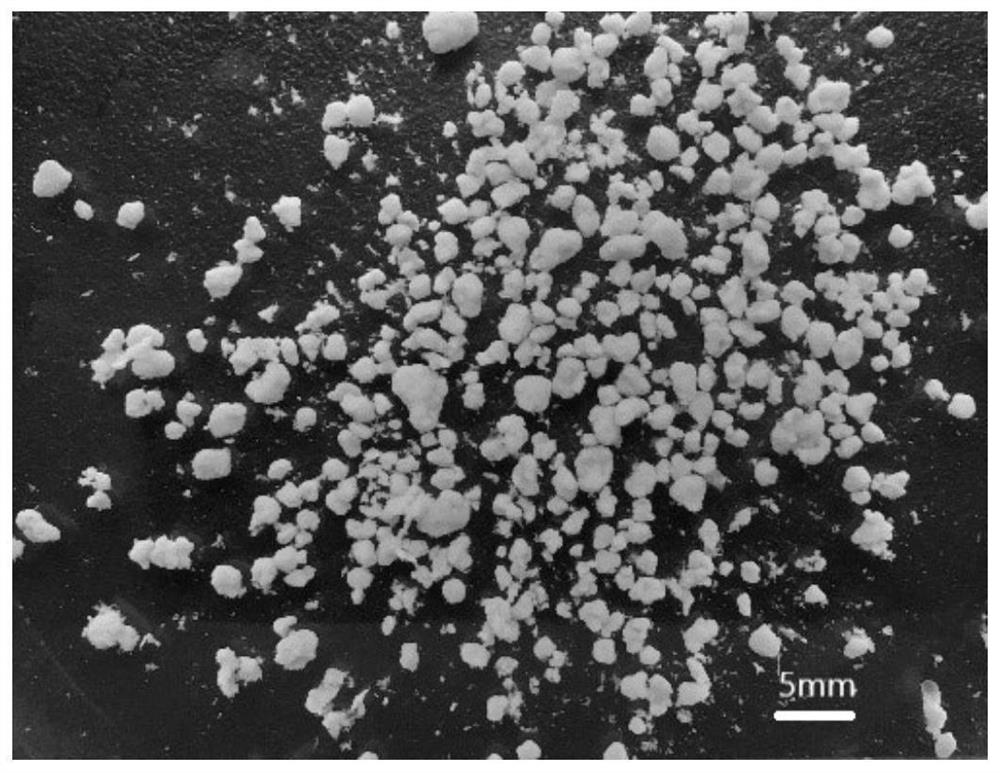

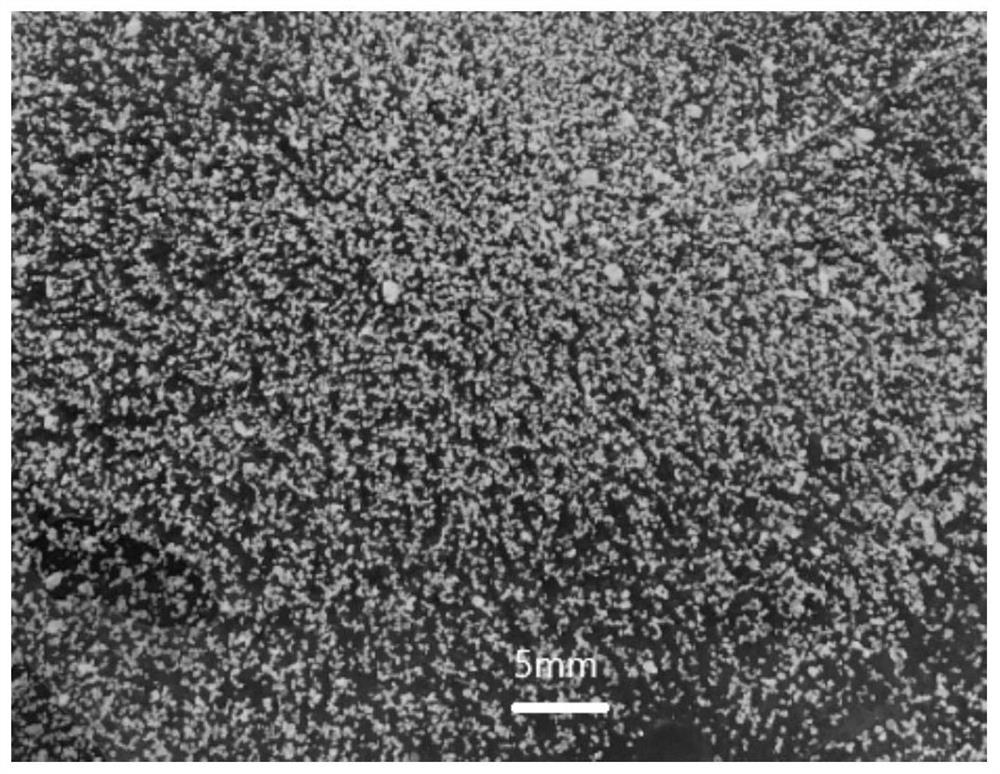

Image

Examples

Embodiment 1

[0033] A method for accelerating the cultivation of aerobic granular sludge based on the NaCl concentration increasing mode, the steps are as follows:

[0034] (1) Preparation of simulated domestic sewage: Prepare simulated domestic sewage so that the concentration of ammonia nitrogen in the sewage is 50 mg / L; COD Cr The concentration is 500mg / L, MgSO 4 ·7H2 O concentration is 25mg / L; FeSO 4 ·7H 2 0 concentration is 25mg / L; CaCl 2 The concentration is 60mg / L; KH 2 PO 4 The concentration is 10mg / L; FeCl 3 ·6H 2 O concentration is 1.5mg / L; EDTA concentration is 20mg / L; KCl concentration is 40mg / L, H 3 BO 3 The concentration is 0.15mg / L; ZnCl 2 Concentration is 0.12mg / L; KI concentration is 0.03mg / L; CuSO 4 ·5H 2 O concentration is 0.03mg / L; NaMoO 4 2H 2 O concentration is 0.15mg / L; CoCl 2 ·6H 2 O concentration is 0.058mg / L; MnCl 2 4H 2 O concentration is 0.12mg / L; Na 2 MoO 4 4H 2 O concentration is 0.15mg / L, with NaHCO 3 Adjust the pH at 7.5 to 8.5,

[0035...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com