Biological removal method of acute biological toxicity in ozonation process

A biological toxicity and process technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution of activated carbon and high disposal cost, and achieve simple operation and low cost , remove the effect of acute biological toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

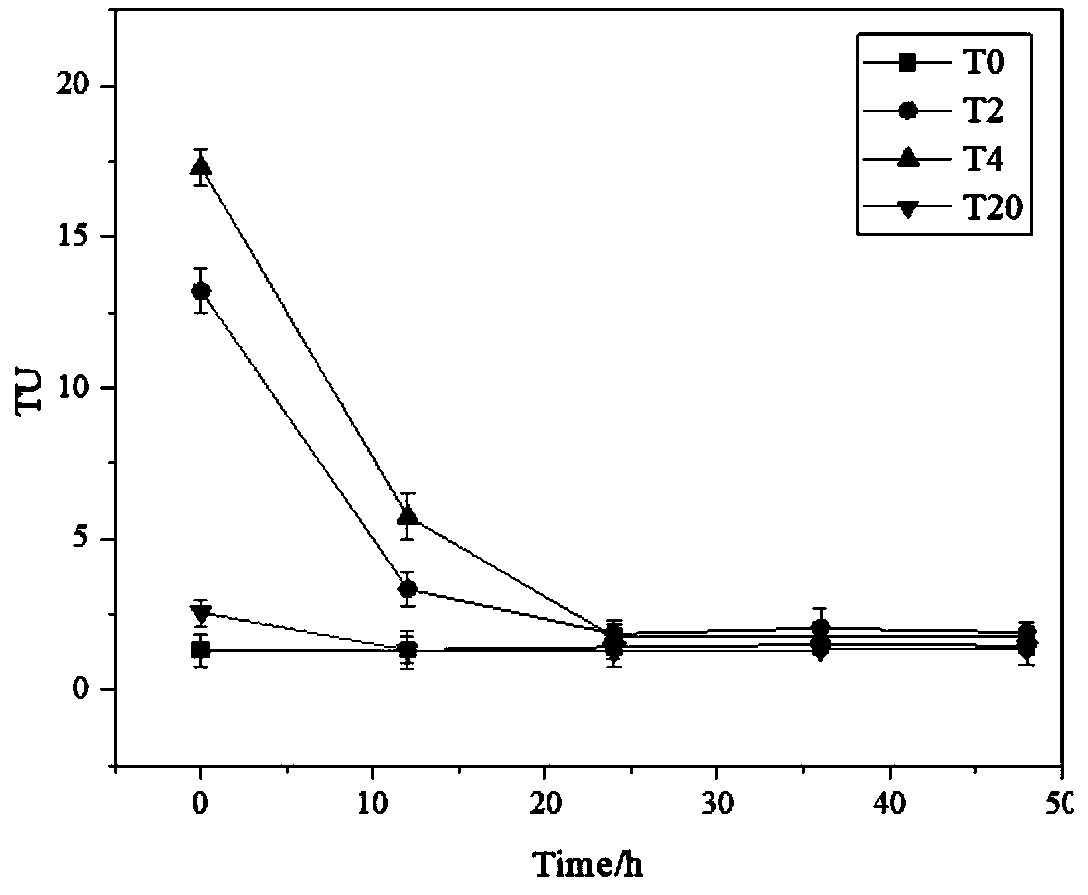

[0023] (1) Use ozone with a concentration of 35mg / L and a flow rate of 0.5L / min to treat 40mg / L of 3-chlorophenol for 20min under the condition of pH=7, and take water samples with different ozone oxidation times for acute biological toxicity removal. (T0, T2, T4 and T20 represent the water samples when ozone was oxidized for 0, 2, 4 and 20 minutes).

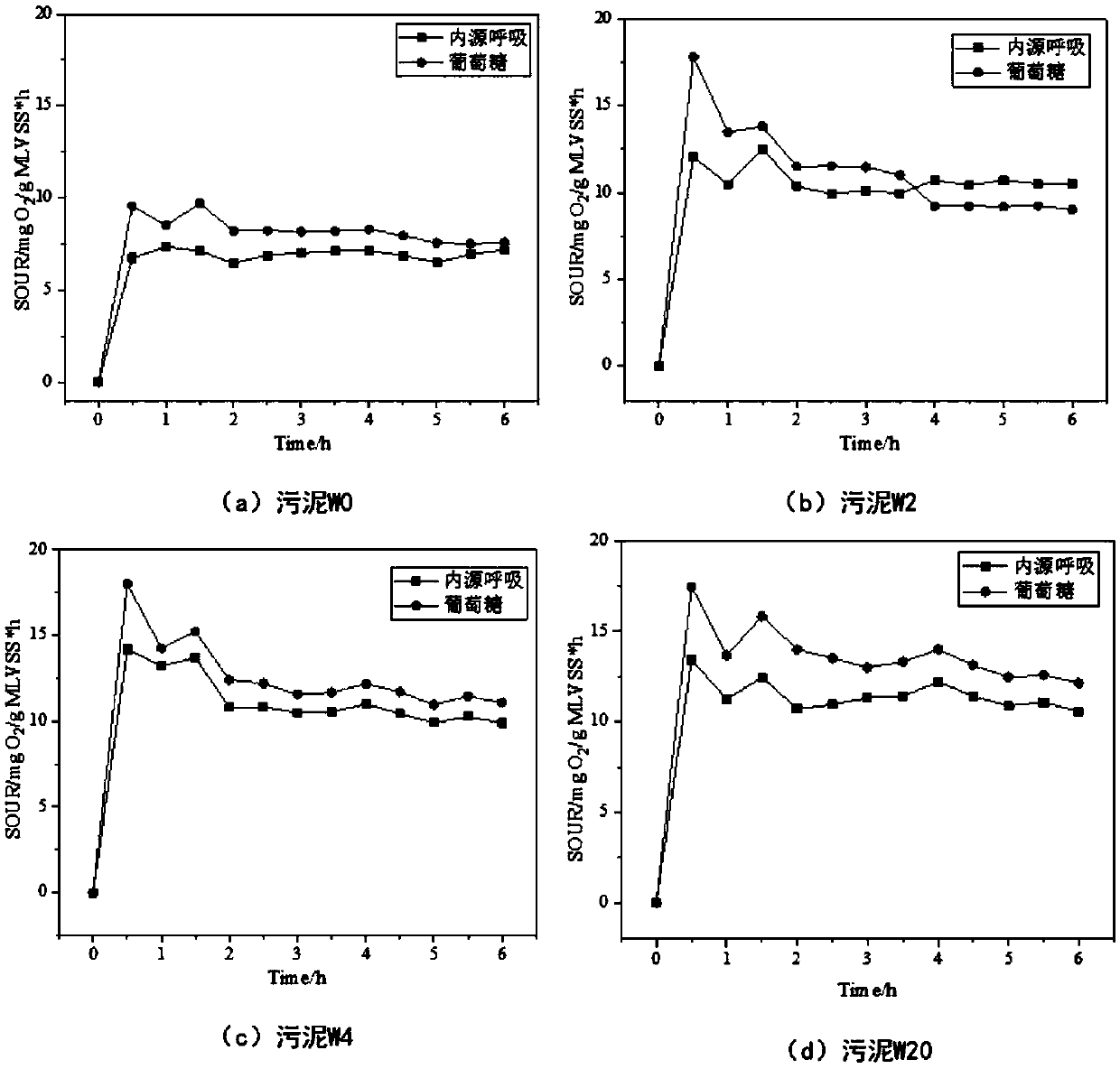

[0024] (2) Take the mixed liquid from the aeration tank of the sewage treatment plant and aerate it continuously and fully for 48 hours, so that the microorganisms in the activated sludge can completely consume the nutrients in the sludge and enter the endogenous respiration period.

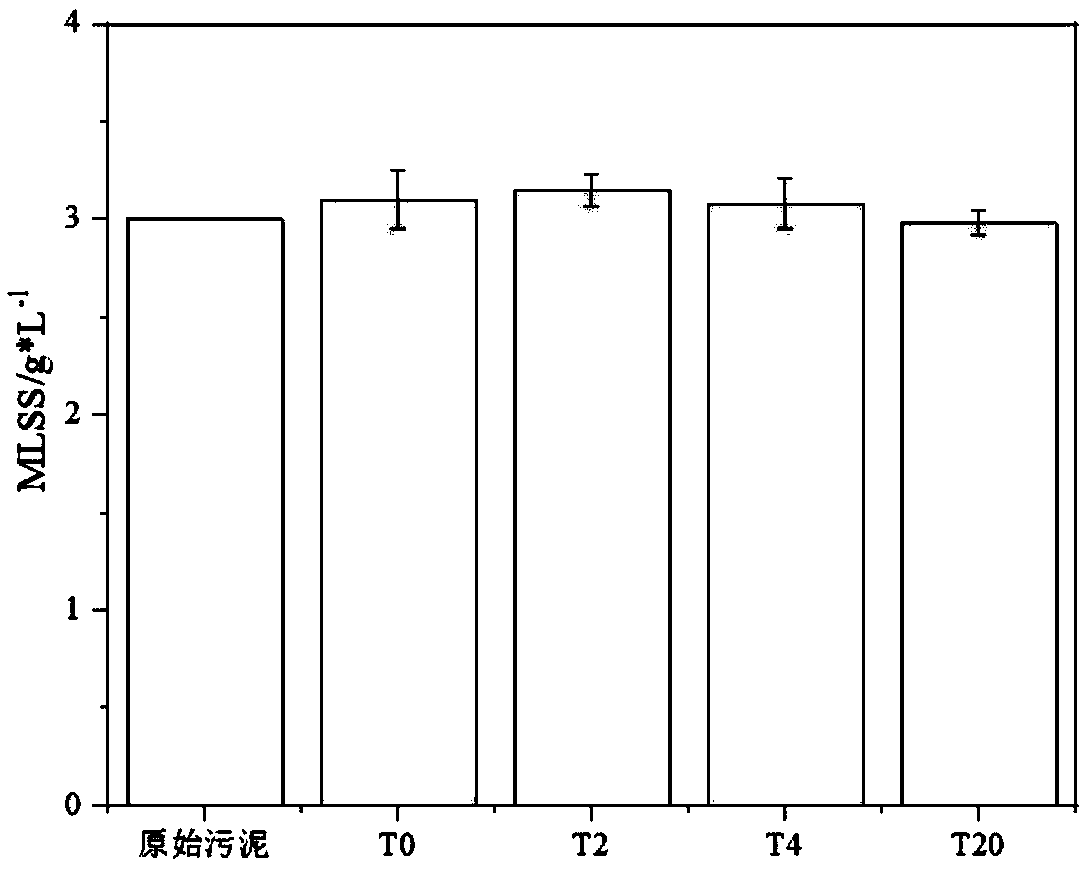

[0025] (3) Add 200mL of 3-chlorophenol ozonated solution into a 250mL conical flask, according to the sludge MLSS, get 0.6g of corresponding volume of sludge, use a centrifuge to concentrate, pour off the supernatant, add to the conical flask, The concentration of MLSS in the bottle is 3000mg / L. Mix the water samples treated with different ozone o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com