Method for preparing polyether polyol by ultrasound-assisted liquefaction of waste water bamboo fibers

A polyether polyol and ultrasonic-assisted technology, which is applied in the field of preparing polyether polyol by liquefaction of wild bamboo waste, can solve the problems of less research and achieve the effects of lower reaction temperature, low raw material cost, and shortened liquefaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

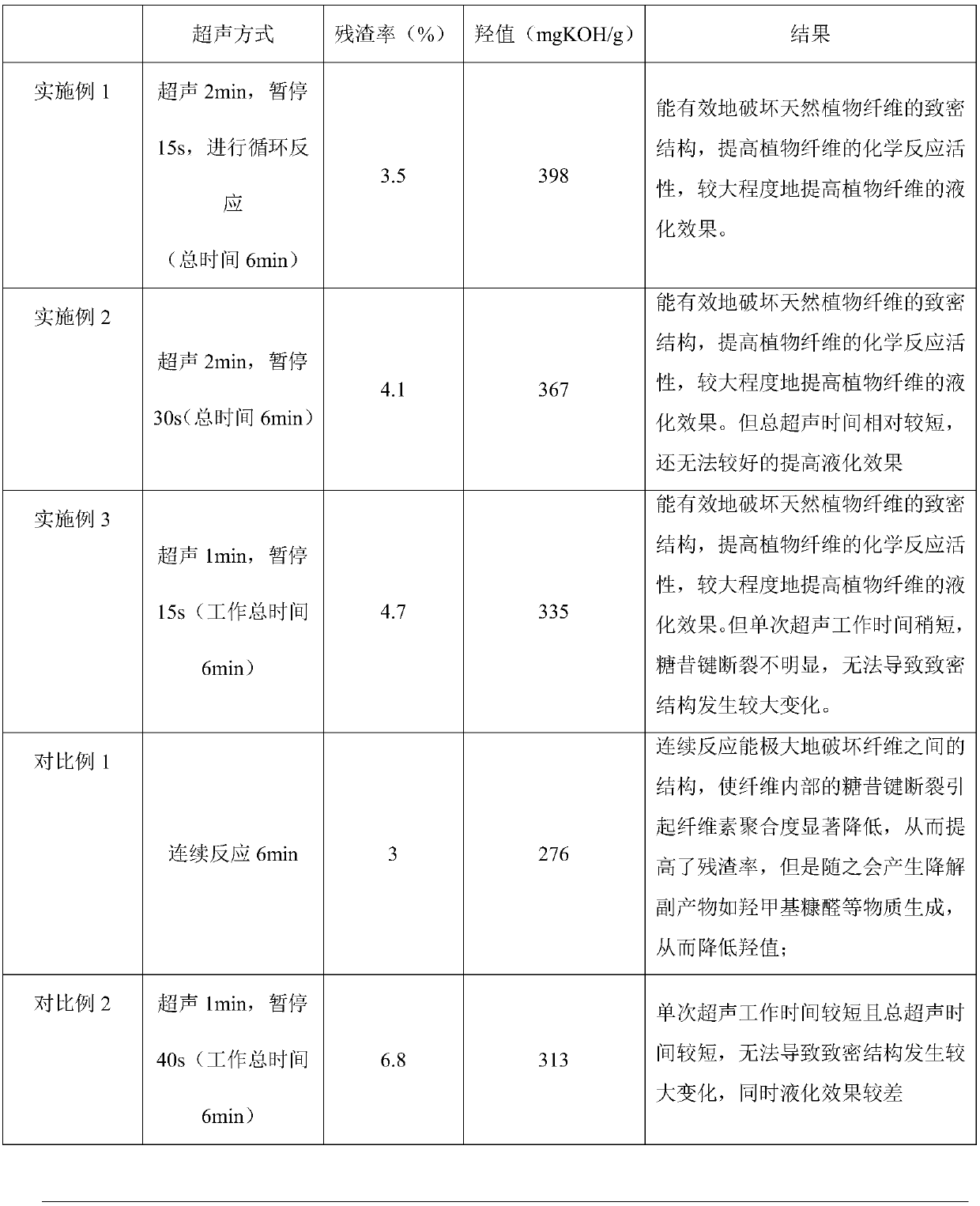

Embodiment 1

[0024] First dry the discarded sheath leaves of Zizania at 50°C overnight, use a pulverizer to pulverize to 40 mesh and sieve to obtain Zizania leaf powder, weigh 1-3g of the powder, put it into polyethylene glycol 400 / glycerol (PEG400: glycerol =4:1) in the mixed liquefaction solvent, the liquid-solid ratio is 8:1, add catalyst (concentrated sulfuric acid), the consumption accounts for 1% of the mixed liquefaction solvent volume, utilize the ultrasonic device that total power is 600W, ultrasonic reaction, reaction time 6min. The ultrasonic conditions are set as shown in Table 1. After the ultrasonic is finished, the temperature is controlled at 100-120°C, and the reaction is stirred at 100r / min for 30min, and the residue rate and hydroxyl value are measured.

Embodiment 2

[0026] First dry the discarded sheath leaves of Zizania zizania at 60°C overnight, pulverize them with a pulverizer, and sieve them through a 80-mesh sieve to obtain Zizania zizania leaf powder. Weigh 1-3g of the powder and put it into polyethylene glycol-400 / glycerol (PEG400: Glycerol=6:1) in the mixed liquefaction solvent, the liquid-solid ratio is 12:1, add catalyst (concentrated sulfuric acid), the dosage accounts for 1% of the volume of the mixed liquefaction solvent, utilize the ultrasonic device with total power of 600W, ultrasonic reaction, reaction The time was 6 minutes, and the ultrasonic conditions were set as shown in Table 1. After the ultrasonic was completed, the temperature was controlled at 100-120°C, and the reaction was stirred at 100 r / min for 30 minutes, and the residue rate and hydroxyl value were measured.

Embodiment 3

[0027] Example 3 Ultrasonic conditions are set as in Table 1, and all the other steps and conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com