Device for smelting magnesium, calcium, strontium and barium

A one-piece, inner tank technology, applied in the field of smelting magnesium, strontium, barium, and calcium, can solve the problems of easy formation of sticky material, low thermal conductivity, high labor intensity, etc., to reduce the reduction cycle, high heat transfer efficiency, The effect of increasing the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

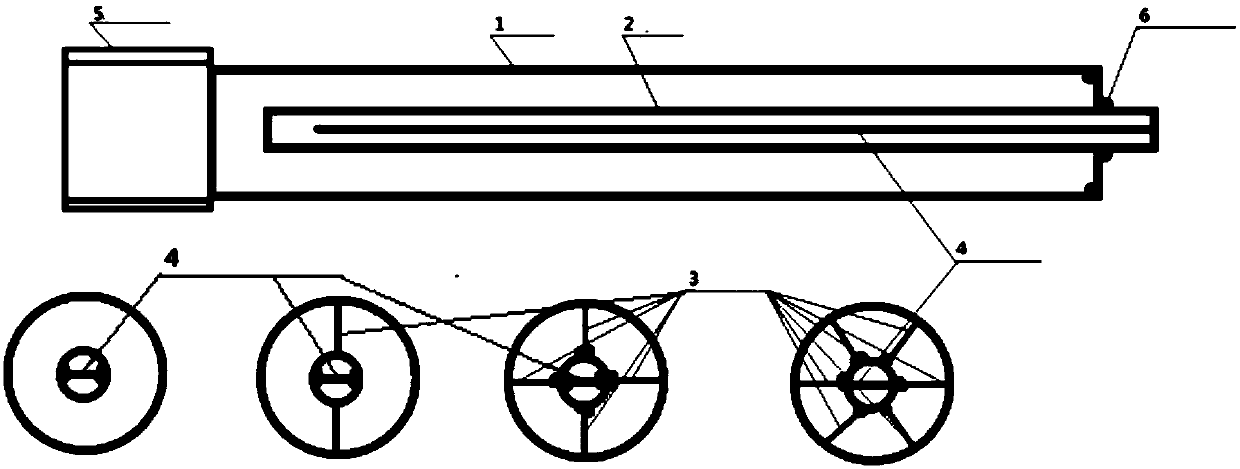

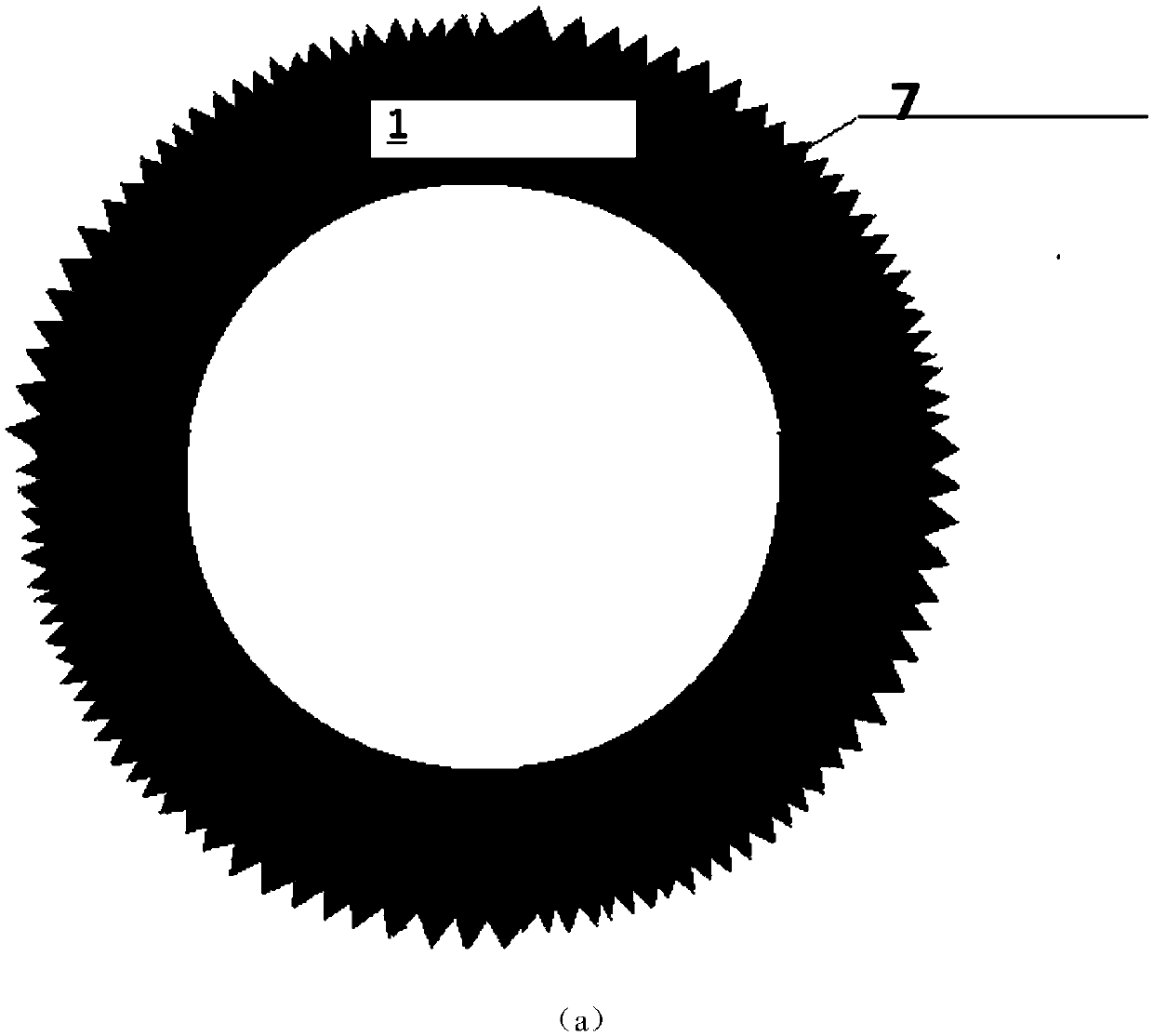

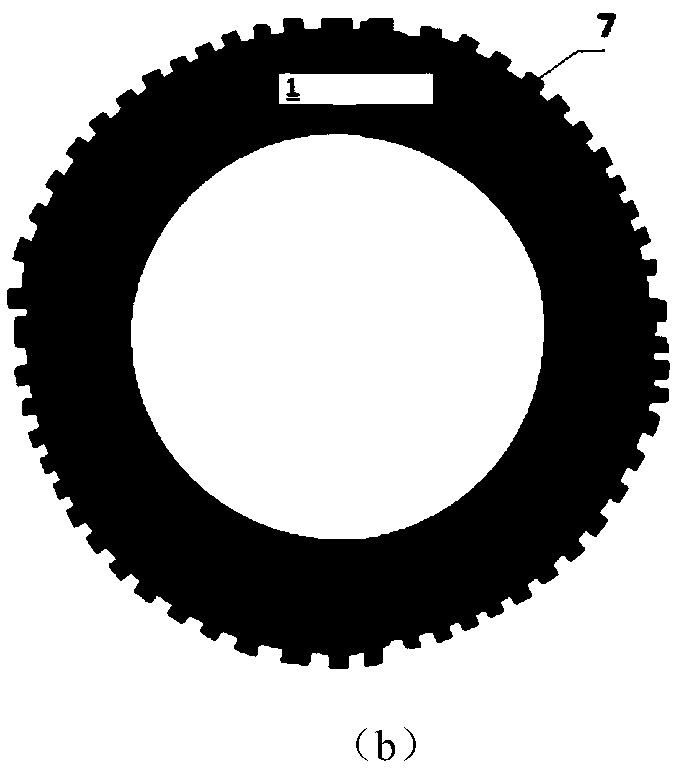

[0031] according to figure 1 Without reinforcing ribs, use a heat-resistant steel reduction tank with a diameter of 350 mm and an inner tank with a diameter of 150 mm to hold 140 kg of pellets (CaO+Al). The method of adding the pellets is as follows: prepare a profiling feeder with a cross-section similar to that of the outer tank but with an outer diameter smaller than the inner diameter of the outer tank by 10 mm and an inner diameter larger than the outer diameter of the inner tank by 10 mm, with both ends sealed and filled with round holes with a diameter of 20 mm. A slot with a width of 70mm is opened along the axis at the top, and the slot is used for adding pellets. Under the conditions of 1250° C. and a vacuum of 5 Pa, after 8 hours, the furnace was turned on to obtain 35 kg of metallic calcium. The reduction rate of the calcium metal is the same as the 12-hour reduction effect of a conventional reduction tank. Therefore, the device strengthens the heat exchange proc...

Embodiment 2

[0034] According to the same equipment described in Example 1, 140 kilograms of pellets were loaded. The pellets were heated at 1250° C. and vacuum 5 Pa, and after 12 hours, the furnace was turned on to obtain 40 kg of metallic calcium.

Embodiment 3

[0036] according to figure 1 In the way of setting two reinforcing ribs, a heat-resistant steel reduction tank with a diameter of 350mm is used to match an inner tank with a diameter of 150mm, and the outer surface of the inner tank is welded with heat-resistant steel reinforcing ribs connected to the inner surface of the outer tank. The transfer of the pellets is loaded into the feeder with two semicircular cross-sections and a feeding port on the upper part. A total of 135 kg (CaO+Al) was fed into two feeders with a semicircular section. Under the conditions of 1250° C. and a vacuum of 5 Pa, after 8 hours, the furnace was turned on to obtain 34 kg of metallic calcium. The reduction rate of the calcium metal is higher than the 12-hour reduction effect of the conventional reduction tank. Therefore, the device strengthens the heat exchange process in the reduction tank and improves the production efficiency.

[0037] The above-mentioned implementation process is all carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com