Preparation method and product thereof of stock solution colored dark black ultrafine chinlon fiber

A nylon fiber, dark black technology is applied in the field of preparing dark black ultra-fine nylon fibers in a raw solution, which can solve the problems of easily broken filaments, poor manufacturability, and difficulty in achieving a dark black color rendering effect, and achieves high market value. , cost controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of dark black chrysanthemum petal nylon fiber with stock solution, according to the following steps:

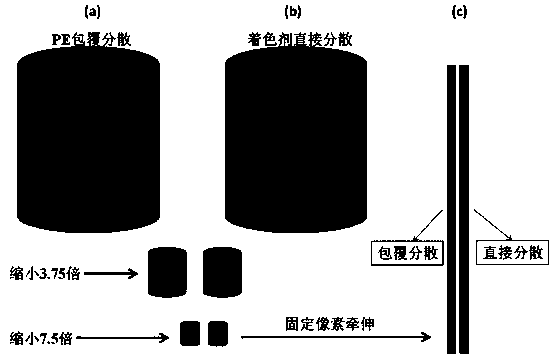

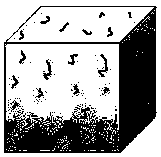

[0031] The first step, the PE composite material of carbon-based colorant: polyethylene PE with 60% addition amount and 40% carbon-based colorant are blended and extruded to obtain PE composite material, wherein the carbon-based colorant is Vantablack carbon nanotube: carbon black =1:9, obtained by homogeneous blending, and the PE composite material of PE-coated carbon-based colorant was prepared by twin-screw blending. Such as figure 2 As shown in the schematic diagram of the homogeneous distribution of the colorant in PE, the colorant of the present invention is uniformly dispersed.

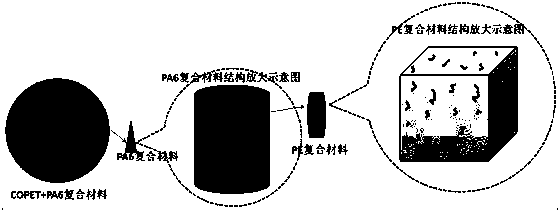

[0032] In the second step, the above-mentioned PE composite material is 30% by mass, the solubilizer maleic anhydride melt-grafted ethylene (PE-g-MAH) 5%, and PA6 65% are melt-blended, extruded and granulated to obtain a high concentration of nylon Black ...

Embodiment 2

[0038] It is similar to Example 1, except that the addition of nylon masterbatch is 7%, the addition of PA6 is 63%, and the sea component material is PET30%, the same blackness, the addition of colorant is less. See Table 2:

[0039] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com