Ultra-thin abrasion layer used for road and preparation method thereof

A wear layer, ultra-thin technology, used in roads, roads, and on-site coagulation pavements, etc., can solve problems such as unfavorable technical application and development, small road surface structure depth, and poor anti-skid performance, to promote application. and development, convenient technical construction and excellent road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

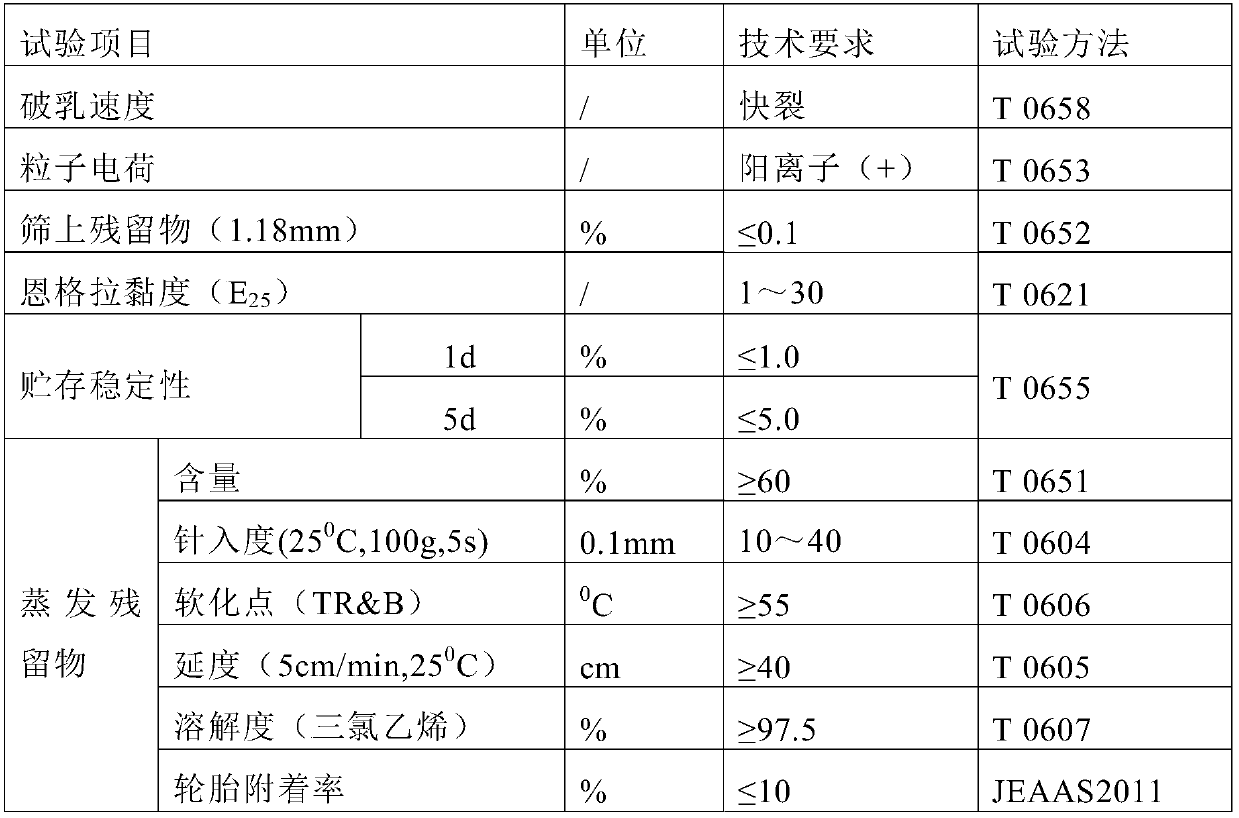

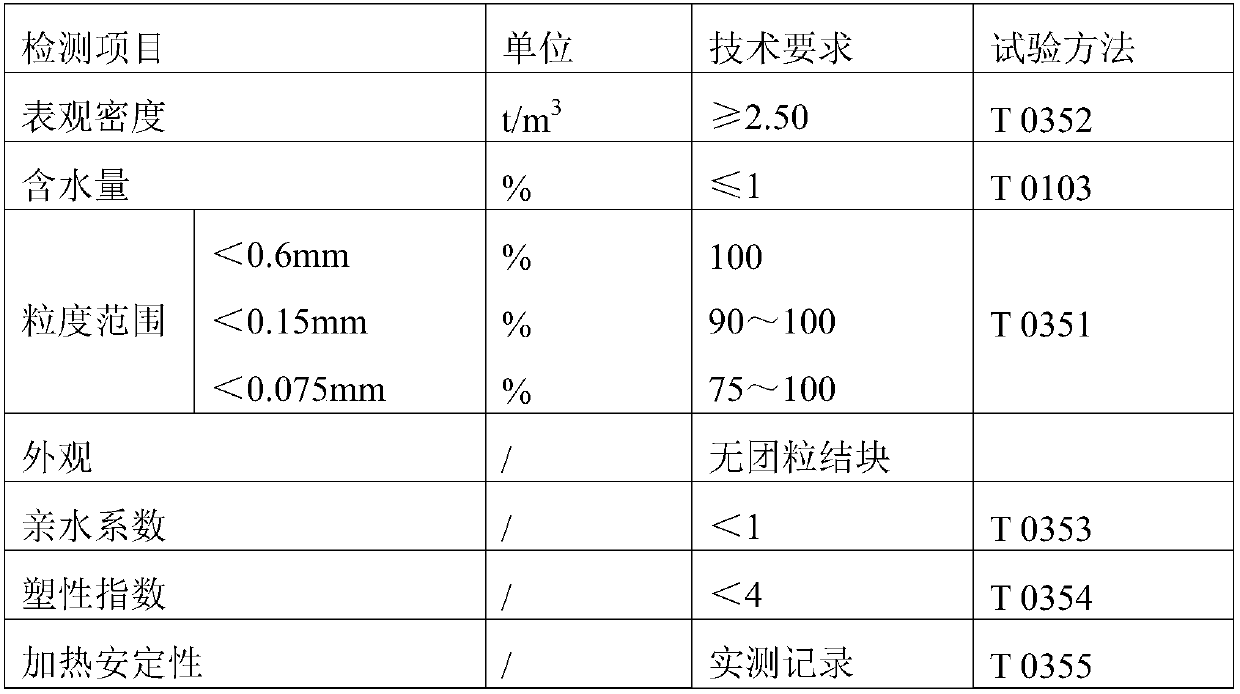

[0060] Embedded modified asphalt mixture material composition:

[0061] Bitumen: Polymer Modified Bitumen

[0062] Coarse aggregate: basalt crushed stone

[0063] Fine aggregate: diabase rock chips

[0064] Filler: limestone powder

[0065] Polyester fiber: 6mm chopped polyester fiber

[0066] The composition ratio of the above materials designed through experiments is shown in Table 5:

[0067] Table 5 Material composition ratio of embedded modified asphalt mixture

[0068]

[0069] Grading of embedded modified asphalt mixture:

[0070] The mineral aggregate gradation of the embedded modified asphalt mixture prepared according to the composition ratio shown in Table 5 is shown in Table 6:

[0071] Table 6 Mineral gradation of embedded modified asphalt mixture

[0072]

[0073] Volume Index of Compacted and Embedded Asphalt Mixture

[0074] The embedded modified asphalt mixture prepared according to the composition ratio shown in Table 5 was aged at a temperature o...

Embodiment 2

[0085] In the present invention, the ultra-thin wear layer formed by the existing ultra-thin construction special-purpose integrated machine that sprays the emulsified asphalt and paves the hot-mix asphalt mixture simultaneously is tested for road performance and interlayer bonding, and the results are as follows:

[0086] Modified asphalt mixture material composition

[0087] Bitumen: Polymer Modified Bitumen

[0088] Coarse aggregate: basalt crushed stone

[0089] Fine aggregate: diabase rock chips

[0090] Filler: limestone powder

[0091] The composition ratios of the above materials are designed as shown in Table 9 through experiments:

[0092] Table 9 Material composition ratio of modified asphalt mixture

[0093]

[0094] Mineral Grading of Modified Asphalt Mixture

[0095] The aggregate gradation of the ultra-thin wearing layer modified asphalt mixture prepared according to the composition ratio shown in Table 9 is shown in Table 10:

[0096] Table 10 Mineral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com