Sliding mold construction device with crane and construction method thereof

A technology of construction equipment and cranes, which is applied in the direction of erecting/assembling bridges, buildings, bridge construction, etc. It can solve the problems of difficult control of formwork verticality, high construction cost, and impact on construction efficiency, so as to improve the poor appearance quality and reduce construction costs. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

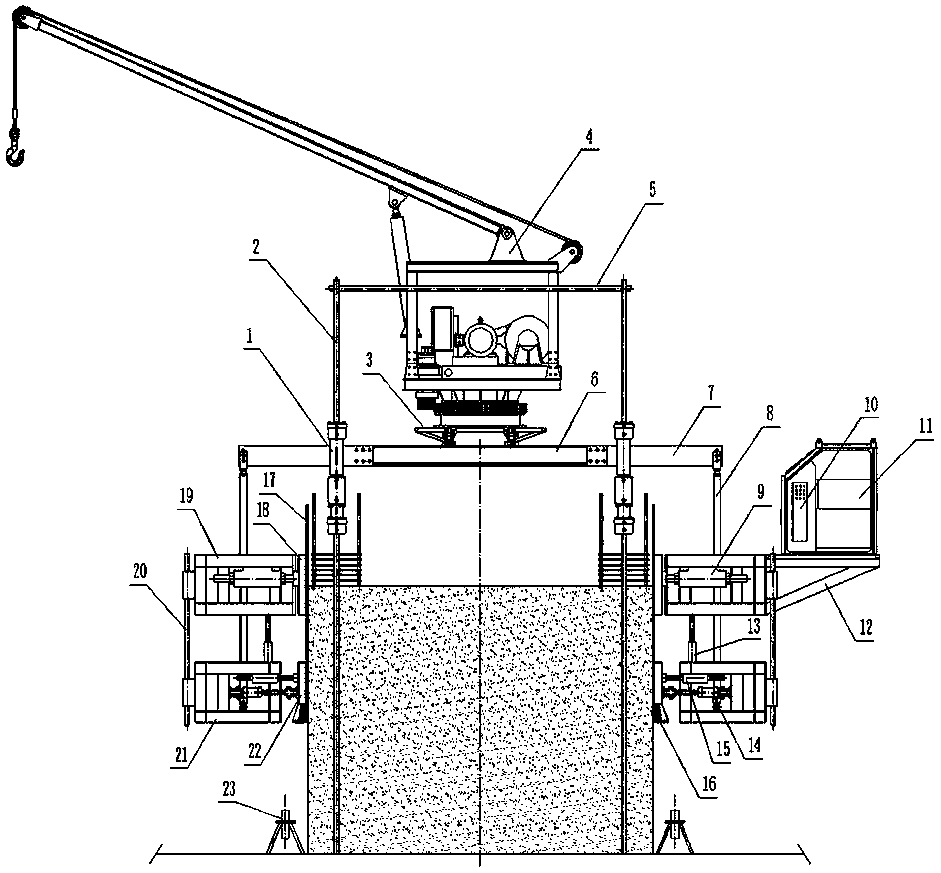

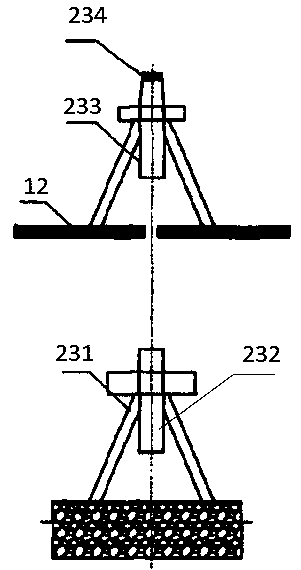

[0063] Such as Figure 1-4 As shown, a slipform construction device with a crane includes a lifting system, a steel structure formwork, a crane 4 and a laser plumb device 23;

[0064] The lifting system includes a jack 1, a hydraulic pump station 11, a control system 10, a jacking cylinder 13 and a clamping cylinder 14; the hydraulic pump station 11 is connected to the jack 1, the jacking cylinder 13 and the clamping cylinder respectively 14 connections; the jack 1 is located on both sides of the top of the concrete seat;

[0065] The control system 10 is connected to a hydraulic pump station 11;

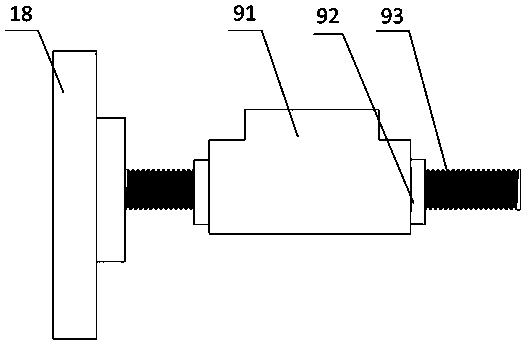

[0066] The steel structure formwork includes a column rod 2, a connecting seat 3, a connecting rod 5, a supporting beam frame 6, a connecting wing plate 7, a boom 8, an adjusting device 9, an operating platform 12, a guiding device 15, a wedge 16, Liner mold 17, sliding formwork 18, upper formwork 19, guide bar 20, lower formwork 21 and clamping formwork 22;

[0067] The column r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com