Double-impeller horizontal shaft wind turbine design optimization method

An optimization method and horizontal axis technology, applied in design optimization/simulation, wind turbines consistent with the wind direction, wind turbines, etc., can solve problems such as large amount of calculation, low efficiency, and inability to predict the aerodynamic performance of the second-stage impeller , to achieve the effect of improving accuracy and speed and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Examples of the embodiments are shown in the accompanying drawings, and the specific embodiments described in the following embodiments of the present invention are only illustrative illustrations of specific embodiments of the present invention, and are intended to explain the present invention, rather than constituting a limitation of the invention.

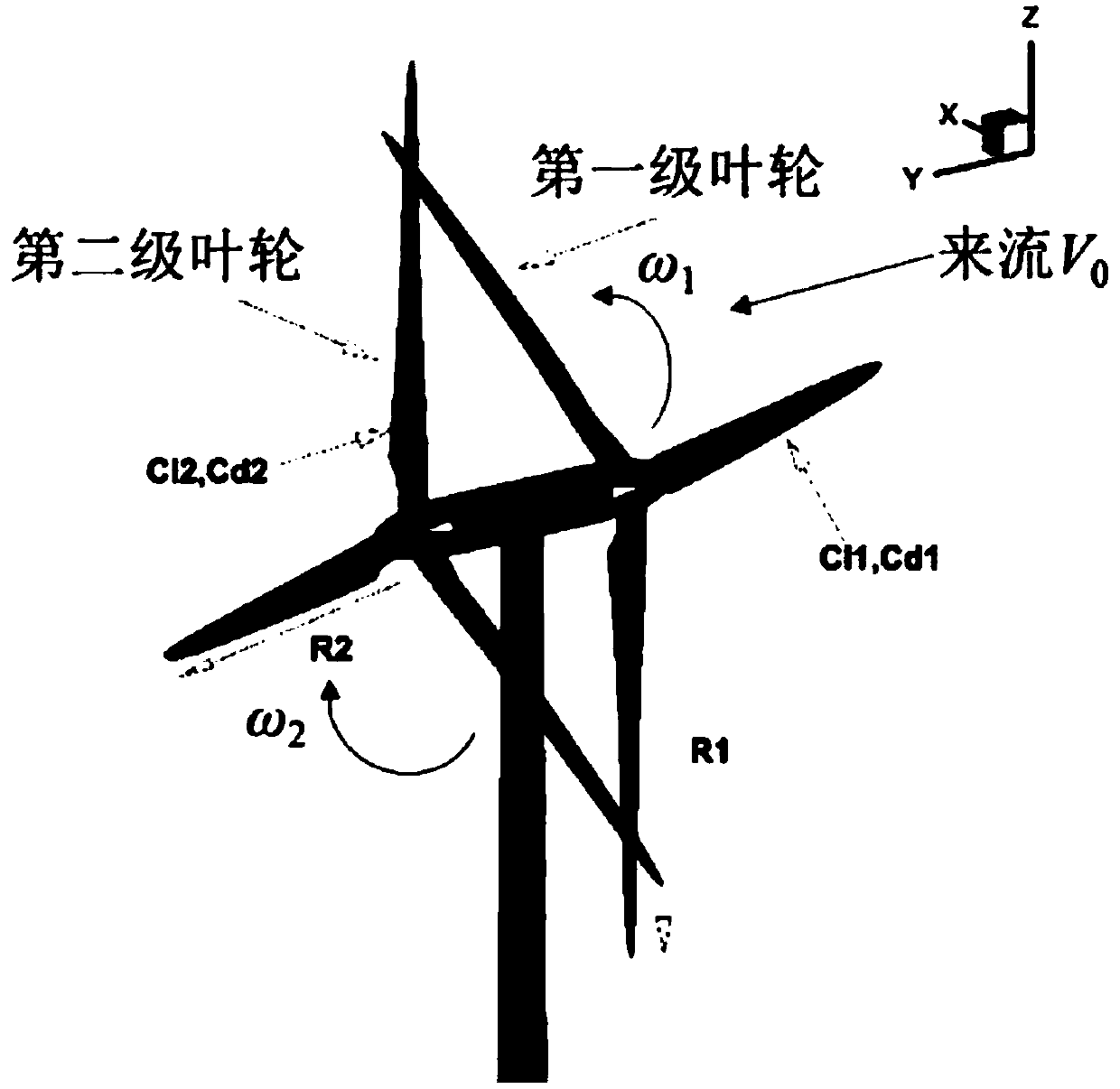

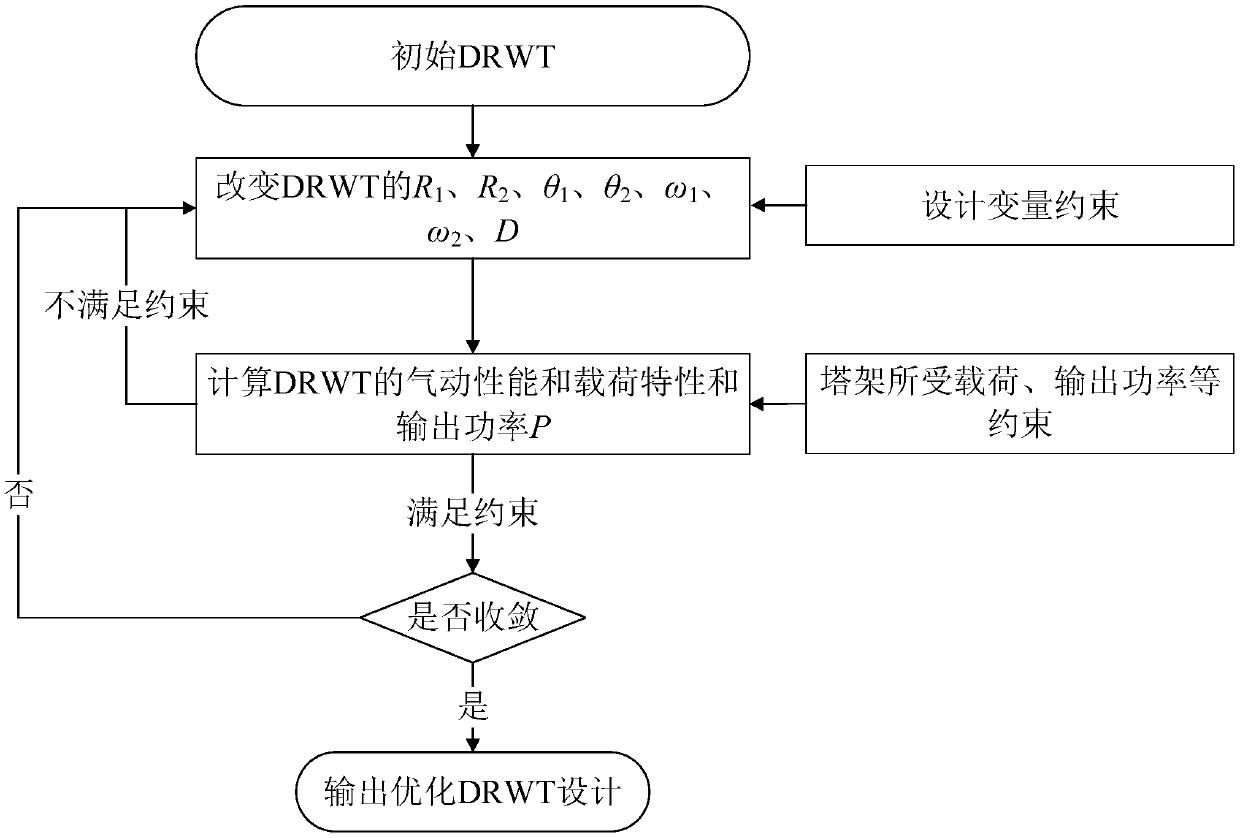

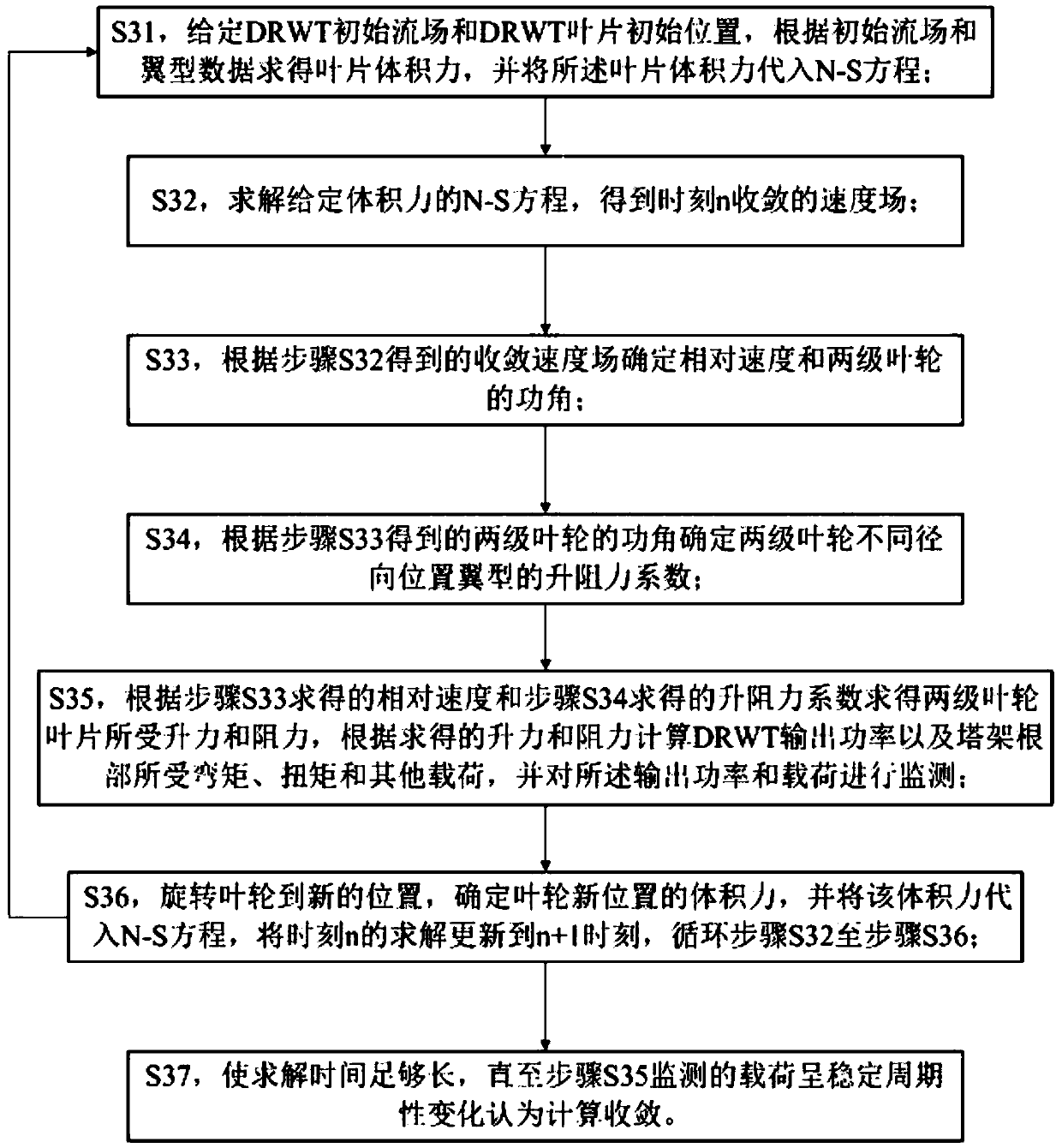

[0034] Two-blade horizontal axis wind turbines, such as figure 1As shown, the radius of the first stage impeller is R 1 , the rotational angular velocity is ω 1 , the pitch angle is θ 1 ;The second-stage impeller radius is R 2 , the rotational angular velocity is ω 2 , the pitch angle is θ 2 ; The distance between the centers of the two-stage impellers is D. The present invention provides a method for optimizing the design of a double-blade horizontal-axis wind turbine, which is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com