Well group return pressure falling metering device

A metering device and well group technology, applied in the direction of cleaning hollow objects, pipeline systems, chemical instruments and methods, etc., can solve the problems of increasing labor intensity of workers, affecting normal production of oil wells, increasing production costs, etc., achieving flexible handling and compact structure , The effect of reducing wellhead pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

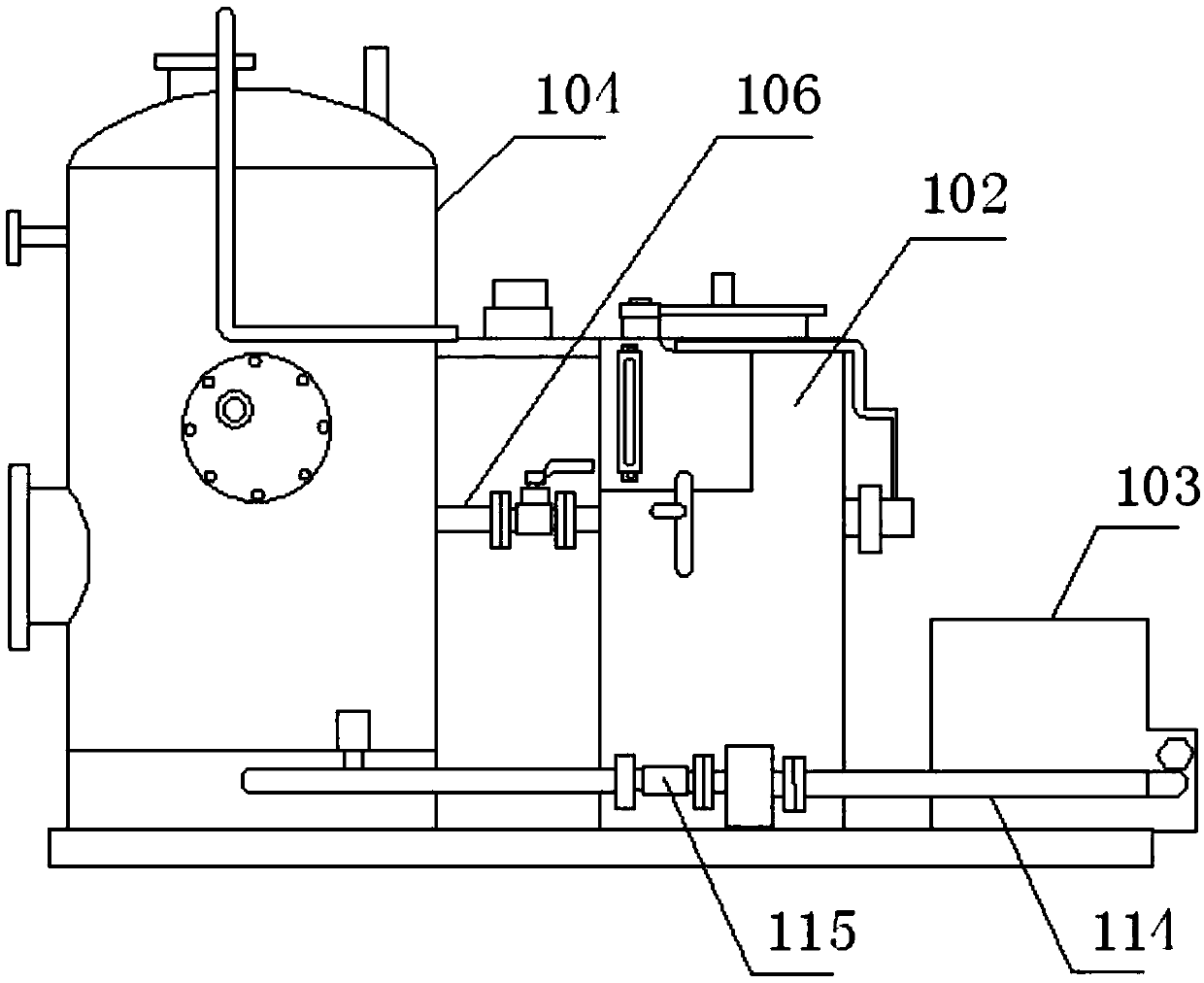

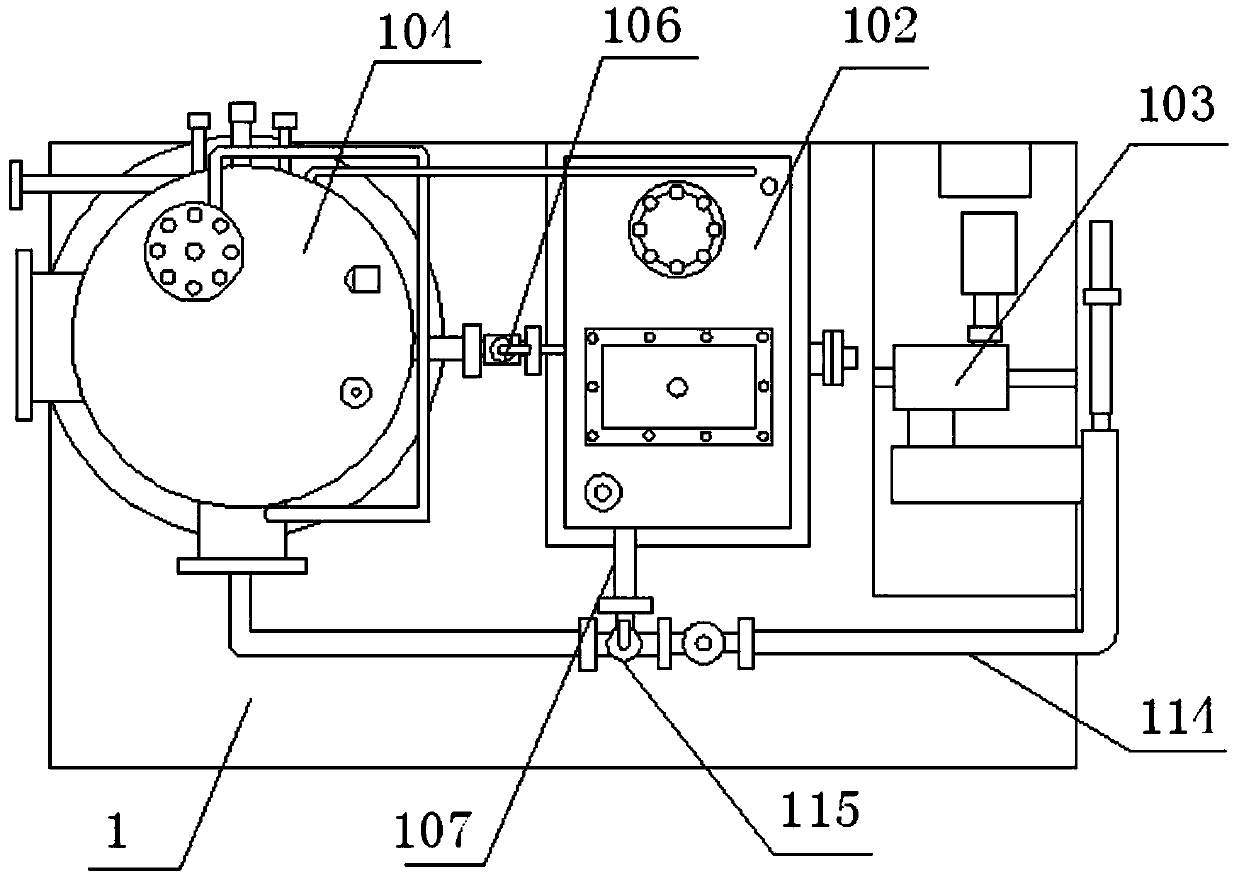

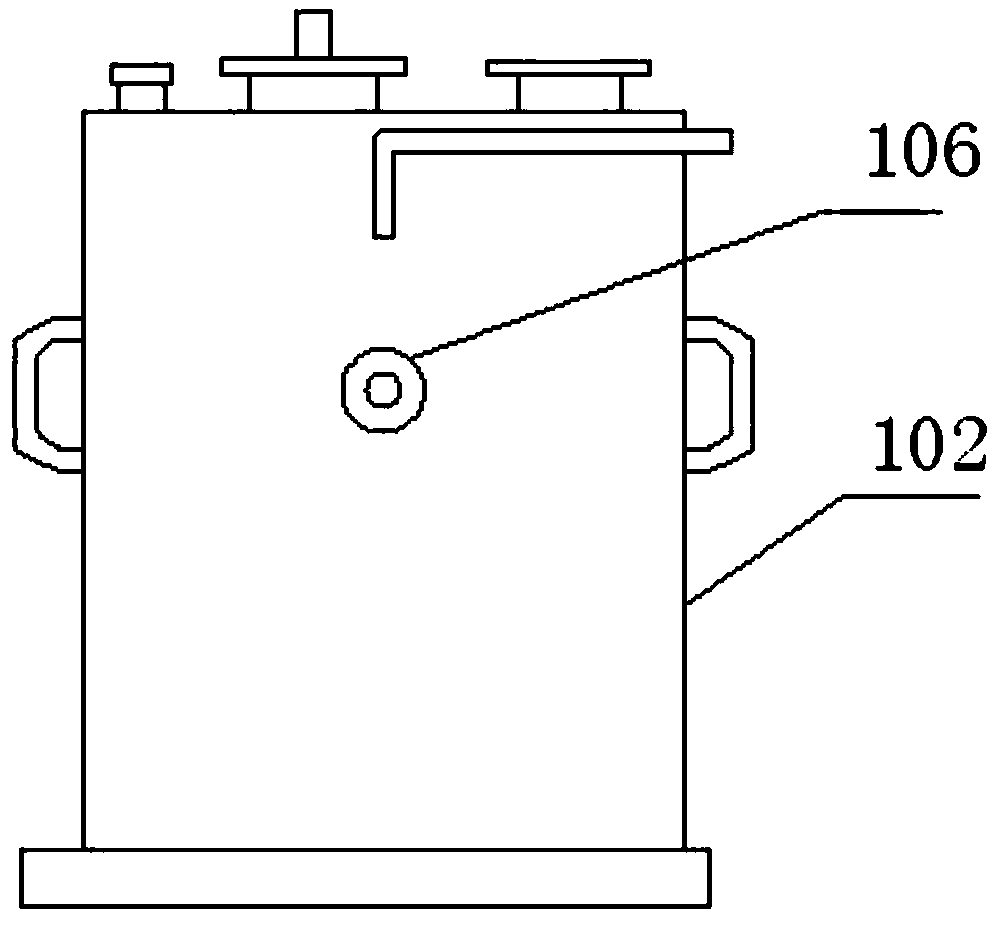

[0025] according to Figure 1-5 A well group pressure reduction and back pressure metering device as shown includes a pressure reduction and back pressure metering unit 1, a data acquisition unit 2, a real-time monitoring unit 3, a data transmission unit 4, a system control unit 5, an auxiliary unit 6 and a control cabinet 7. The combination of each system unit is beneficial to make the device have the advantages of high degree of automation, high test accuracy, flexible handling, convenient installation, compact structure, safety and reliability, and easy operation, etc., and effectively realize the integrated structure. 1 includes a heating furnace 101, a tipping bucket meter 102, a booster pump 103, an oil-water separator 104 and a dosing device 105, the real-time monitoring unit 3 includes a flow sensor, a temperature sensor, a pressure sensor, a liquid level sensor, a current sensor, a voltage sensor Sensor and power sensor, the system control unit 5 includes CPU, power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com