Lithium battery coating defect detection method, system and device and storage medium

A defect detection, lithium battery technology, applied in optical testing flaws/defects, measuring devices, material analysis by optical means, etc., can solve the problems of high recognition rate and low resource utilization rate, and achieve high recognition rate and utilization rate. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. It should be noted that, on the premise of no conflict, the embodiments or technical features described below can be combined arbitrarily to form new embodiments. .

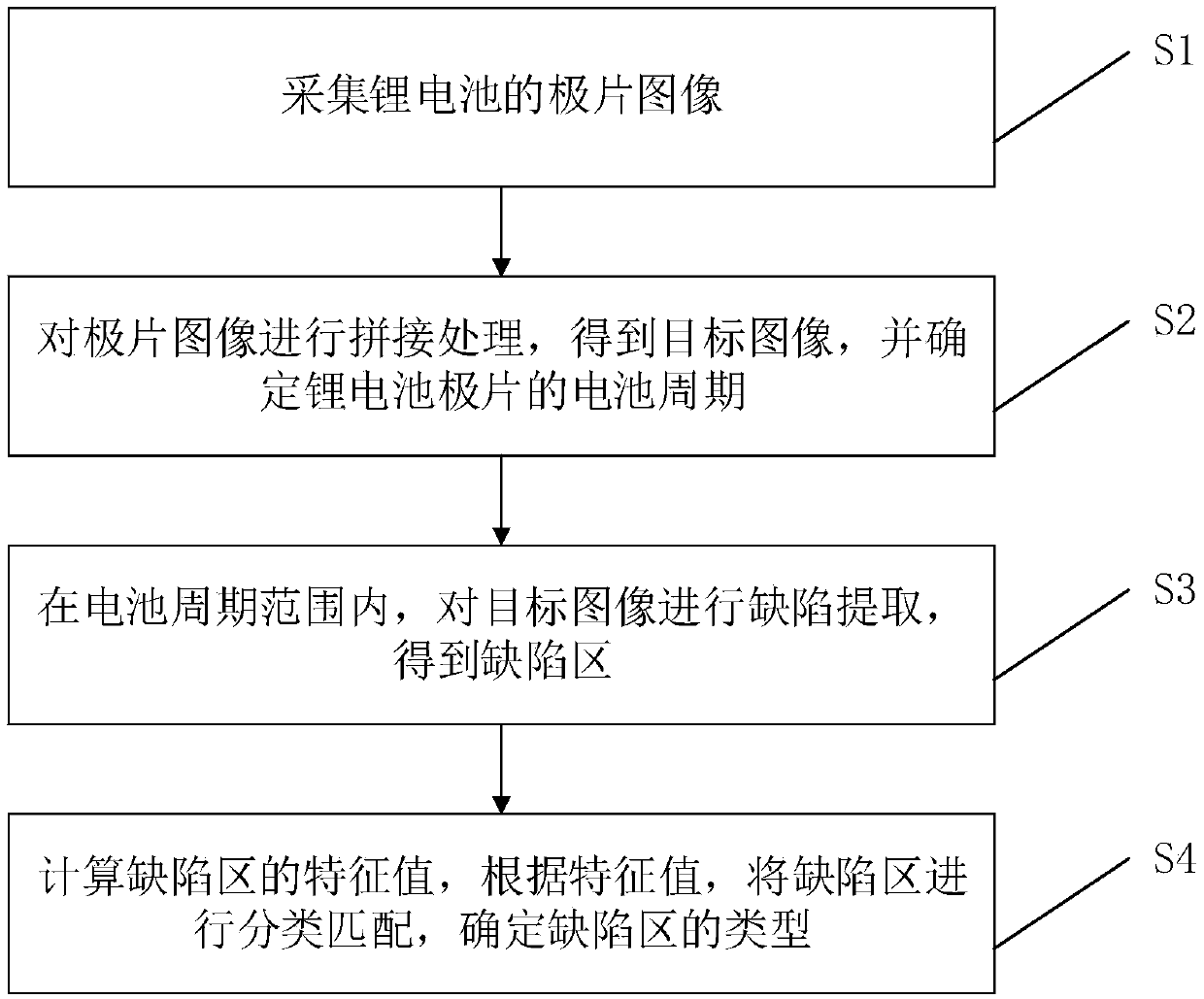

[0044] see figure 1 , is a flowchart of the method for detecting coating defects of lithium batteries provided by the first embodiment of the present invention. The lithium battery coating defect detection method of this embodiment includes the steps:

[0045] S1: Collect the pole piece image of the lithium battery.

[0046] This step is used to collect the image of the pole piece after coating of the lithium battery. The coating process in the formation of lithium batteries is to coat the configured positive electrode slurry and negative electrode slurry on the substrate such as aluminum foil or copper foil. After the lithium battery pole piece of the spacer process is coated, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com