The invention discloses a dDefect detection method for a solar cell panel

A solar panel and defect detection technology, applied in the field of visual inspection, can solve the problems of low detection efficiency, high manpower and material resources consumption, battery damage, etc., and achieve the effect of improving iteration accuracy, reducing the number of iterations, and reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

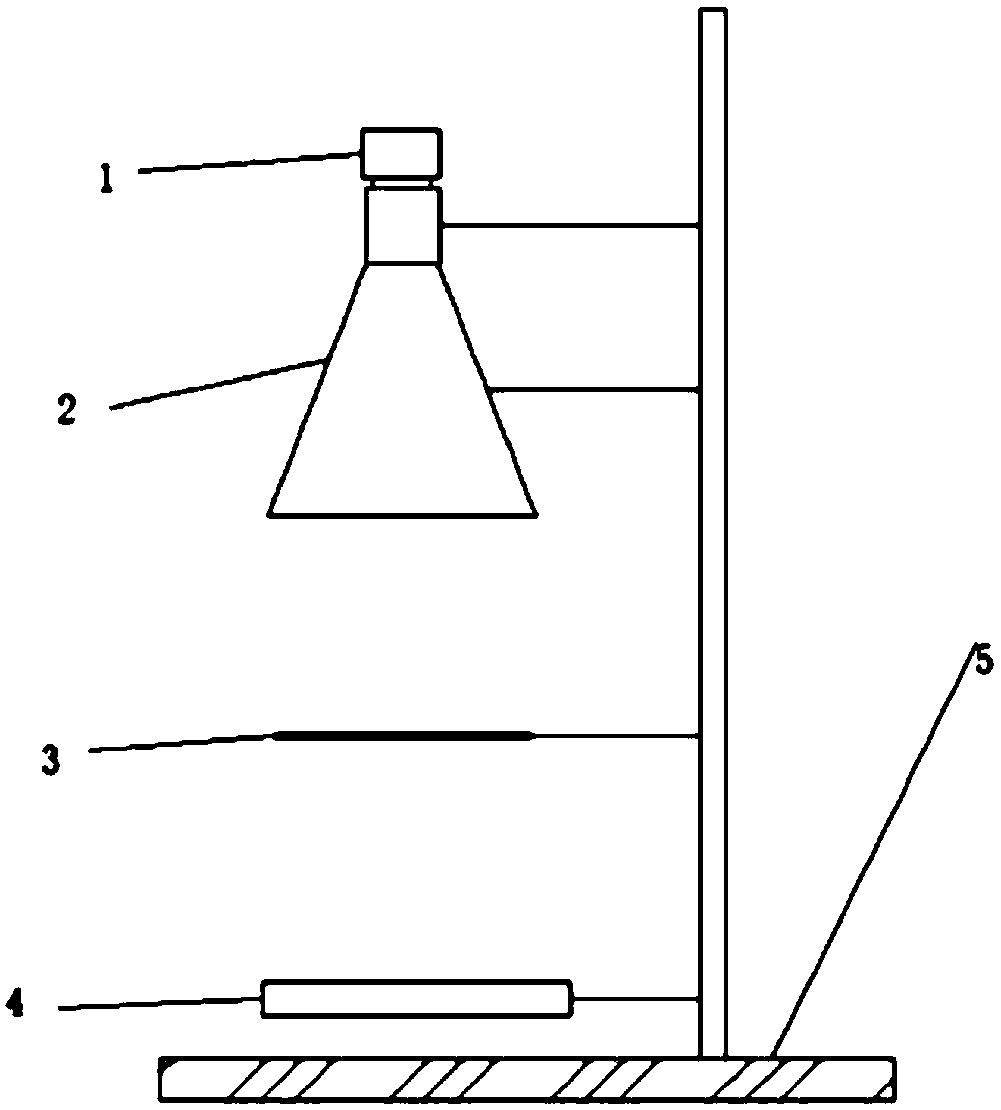

[0045] The present invention provides a defect detection method of a solar cell panel. The visual detection method is realized by a measurement system composed of a test frame 5, a color area array camera 1, a telecentric lens 2, a base light source 4 and a stage 3. The specific position and structural relationship of the components of the measurement system can be further referred to figure 2 , the hardware installation of the measurement system should meet the requirements that the axes of the color area array camera 1, the telecentric lens 2, the stage 3 and the base light source 4 are parallel, and the stage 3 is installed within the depth of field of the telecentric lens 2.

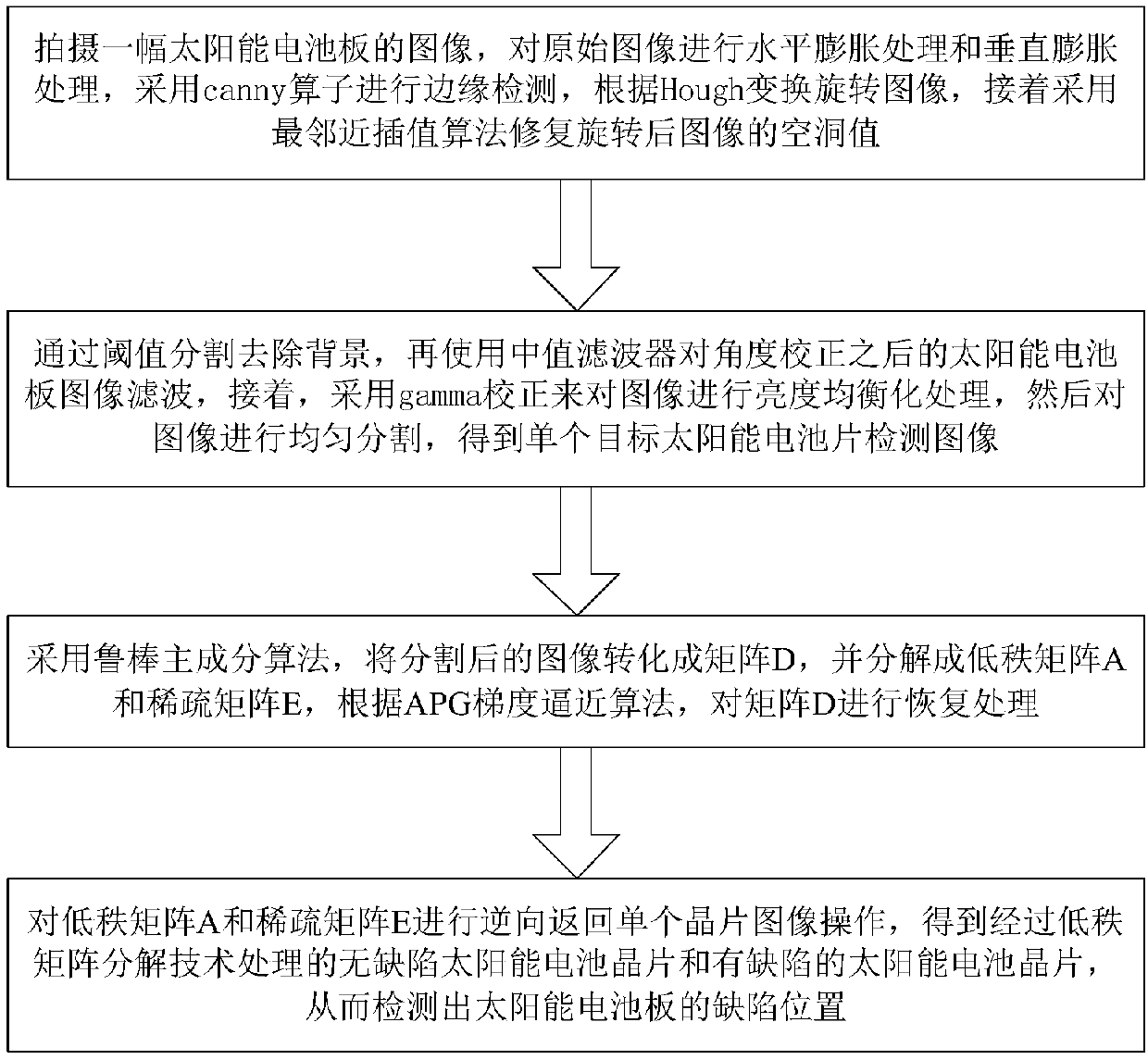

[0046] The defect detection method using the measurement system as a detection tool includes the following steps:

[0047] S1. Take an image of a solar panel, adjust the angle, and then horizontally expand the original image

[0048] Expansion processing, connecting the edges in the horizontal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com