A microwave-ultrasonic coupling cavity suitable for liquid materials

A technology of microwave ultrasonic and coupled cavity, which is applied in the field of microwave-ultrasonic coupled cavity to reduce the risk of electromagnetic wave reflection, ensure safety performance, and improve the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

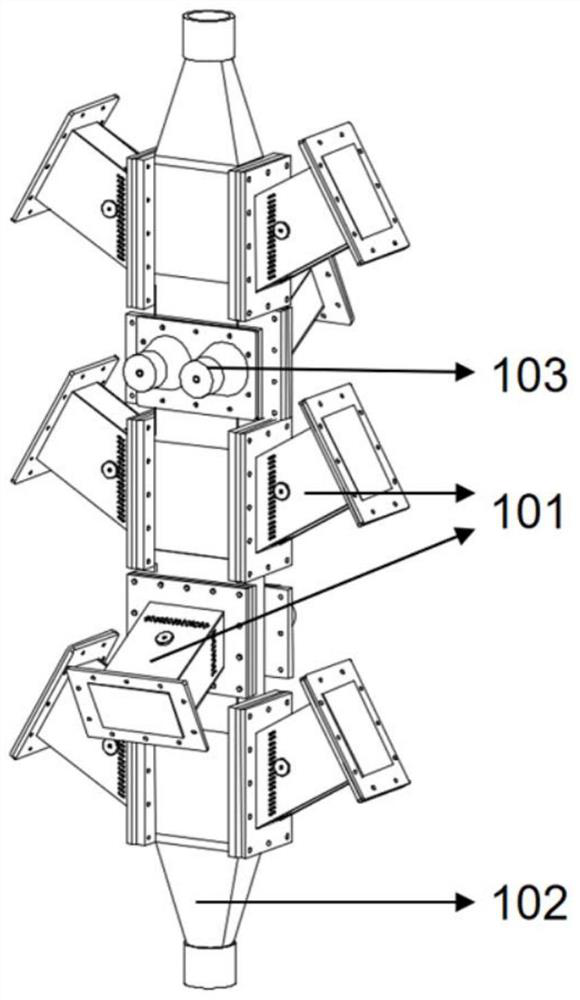

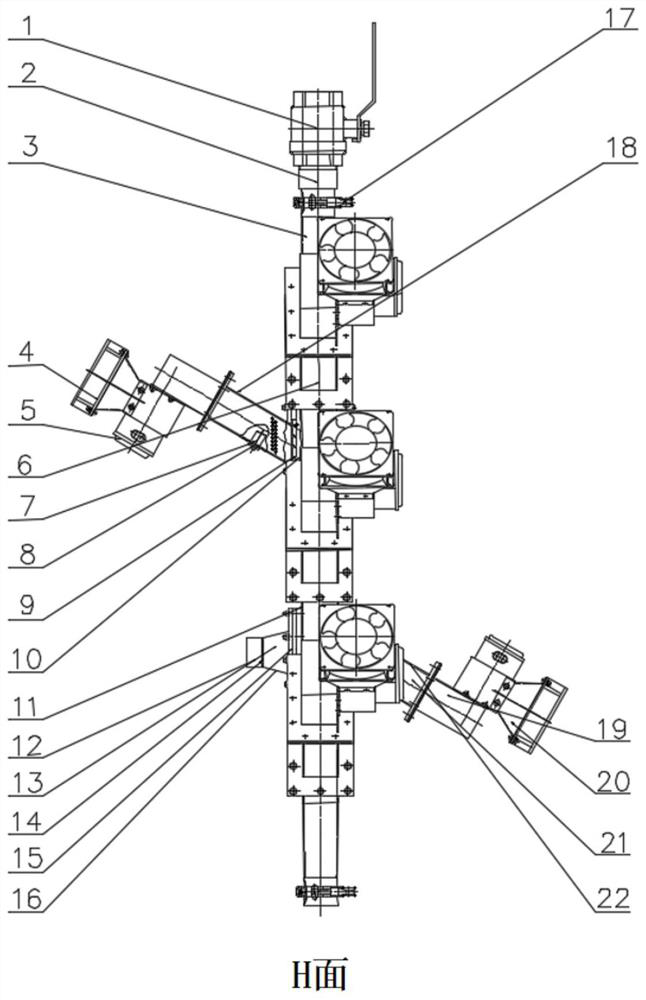

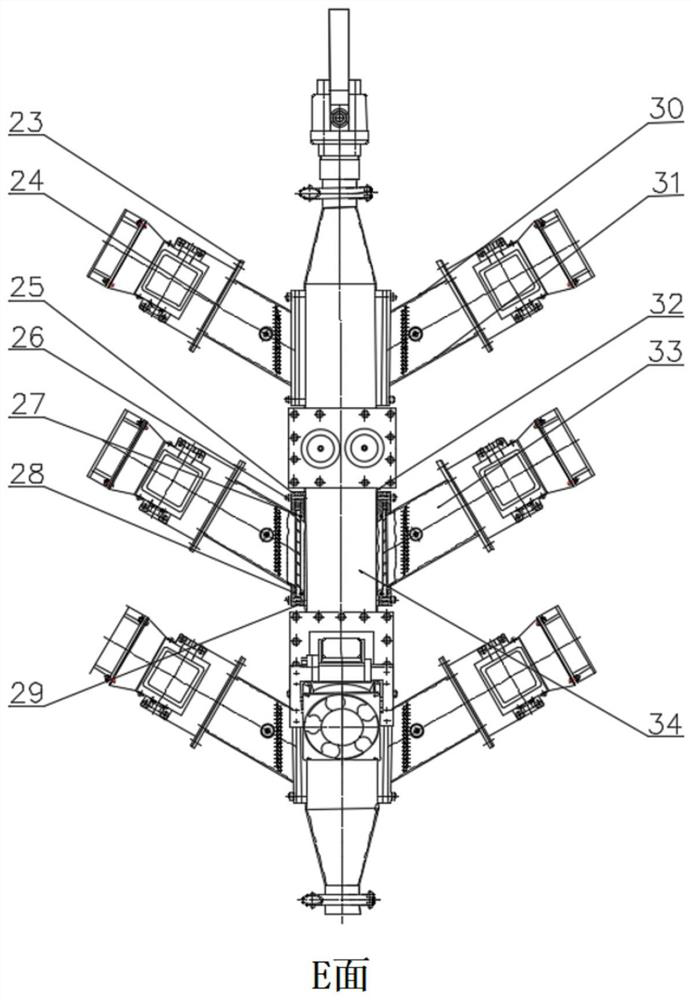

[0030] This embodiment provides a microwave-ultrasonic coupling cavity, please refer to figure 1 , the microwave-ultrasonic coupling cavity includes: a waveguide system 101, a material carrying cavity 102 and an ultrasonic system 103; the cavity of the material carrying cavity 102 includes at least a pair of ultrasonic systems 103 and waveguide systems 101 corresponding to each other, the Each waveguide in the waveguide system 101 is connected to the wall of the material carrying cavity at a predetermined angle, and the predetermined angle is greater than or equal to 15° and less than 90°.

[0031] The ultrasonic system 103 includes at least one ultrasonic generating device. When the ultrasonic system 103 includes more than two ultrasonic generating devices, the ultrasonic generating devices are installed alternately on opposite walls of the material carrying cavity 102 and opposite to the waveguide.

[0032] The predetermined angle range is [30°, 60°].

[0033] The material ...

Embodiment 2

[0051] The microwave-ultrasonic coupling treatment device provided in Example 1 can be used to process fluid substances in the fields of chemical industry, food, and medicine. For example, refer to Image 6 , provides a continuous microwave-ultrasonic coupling sterilization equipment that uses the microwave-ultrasonic coupling cavity to carry out microwave-ultrasonic coupling sterilization of fluid materials. The microwave-ultrasonic coupling sterilization equipment includes: feed preheating section 201, microwave-ultrasonic Coupling processing device 202, constant temperature sterilization section 203 and cooling receiving section 204;

[0052] First, in the preparation stage for the use of the continuous microwave-ultrasonic coupling processing equipment, use the network analyzer to adjust the position of the adjuster in the waveguide system by measuring the S11 parameter and voltage standing wave ratio, so that it can play the expected role; then check the equipment Whether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com