Novel efficient mixing crusher

A pulverizer, high-efficiency technology, applied in the direction of agricultural machinery and tools, cutting equipment, applications, etc., can solve the problems of incomplete crushing of raw materials, inability to mix raw materials, and easy occurrence of dead angles, etc., to achieve convenient rotation speed, improve mixing effect, and improve The effect of rotational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

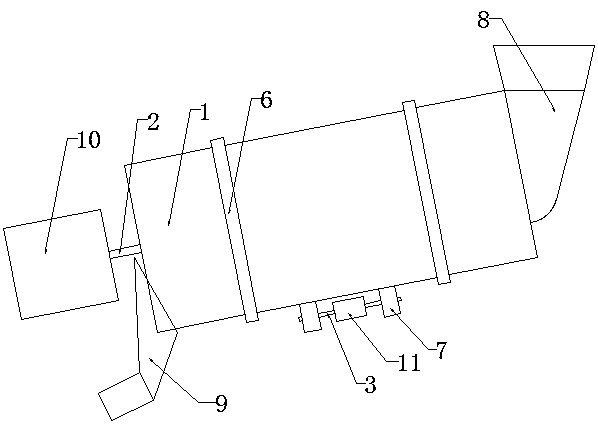

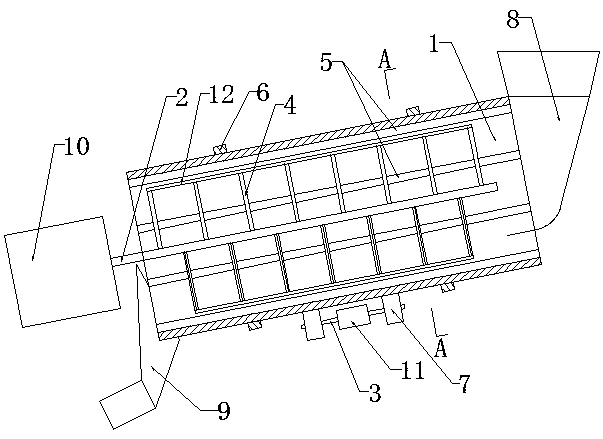

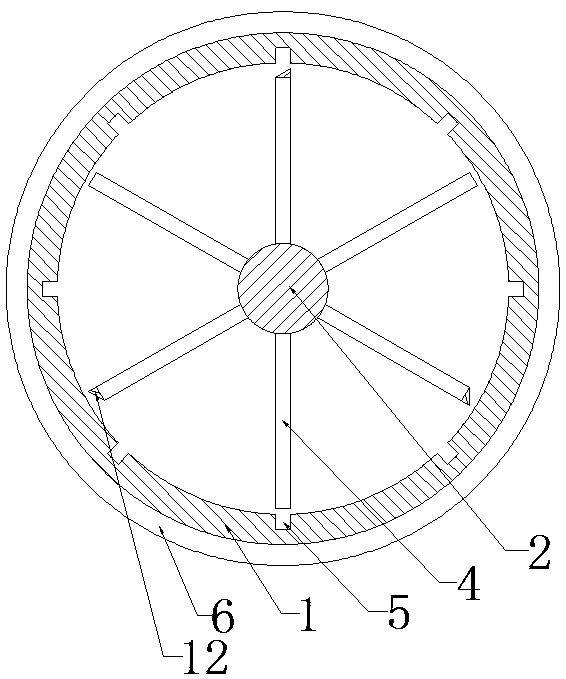

[0025] as attached figure 1 , 2 As shown in , 3, a new type of high-efficiency mixing pulverizer includes a cylinder body 1, a rotating shaft 2 and a rotating shaft 3, the rotating shaft 2 is arranged at the central axis of the cylinder body 1, and the rotating shaft 2 is fixed with a The radial crushing knife 4 of the vertical rotating shaft 2, the inner wall of the cylinder body 1 is provided with a groove 5, the outer side of the cylinder body 1 is fixed with a support ring 6, and the lower side of the cylinder body 1 is provided with the cylinder body. 1. A parallel rotating shaft 3, a rotating wheel 7 is arranged on the rotating shaft 3, and the rotating wheel 7 is in contact with the outer side of the cylinder body 1.

[0026] The left end of the cylindrical body 1 is inclined downward, the right end of the cylindrical body 1 is provided with a feeding hopper 8 , and the left end of the cylindrical body 1 is provided with a collection groove 9 .

[0027] The rotating s...

Embodiment 2

[0037] as attached figure 1 , 4 , 5, a new type of high-efficiency mixing pulverizer includes a cylinder body 1, a rotating shaft 2 and a rotating shaft 3, the rotating shaft 2 is arranged at the central axis of the cylinder body 1, and the rotating shaft 2 is fixed with The radial crushing knife 4 of the vertical rotation axis 2, the inner wall of the cylinder body 1 is provided with a groove 5, the outer side of the cylinder body 1 is fixed with a support ring 6, and the lower side of the cylinder body 1 is provided with the cylinder body. 1. A parallel rotating shaft 3, a rotating wheel 7 is arranged on the rotating shaft 3, and the rotating wheel 7 is in contact with the outer side of the cylinder body 1.

[0038] The left end of the cylindrical body 1 is inclined downward, the right end of the cylindrical body 1 is provided with a feeding hopper 8 , and the left end of the cylindrical body 1 is provided with a collection groove 9 .

[0039] The rotating shaft 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com