Electronic cigarette heating element

A heating element and electronic cigarette technology, applied in tobacco, smoker's products, applications, etc., can solve the problems of heating temperature affecting the user's smoking taste, unable to control the heating temperature of smoking substances, and not having a temperature control function, etc., to prevent tar Or the production of other toxic substances, improve the heating effect, the effect of good transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

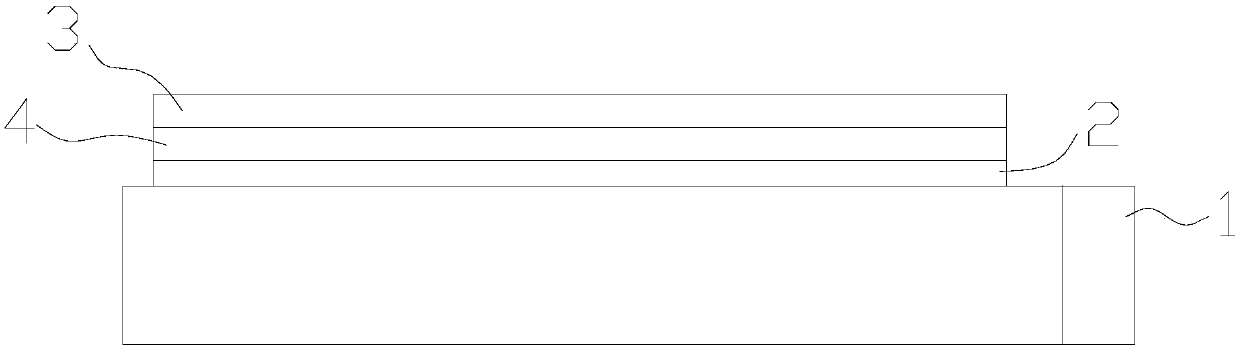

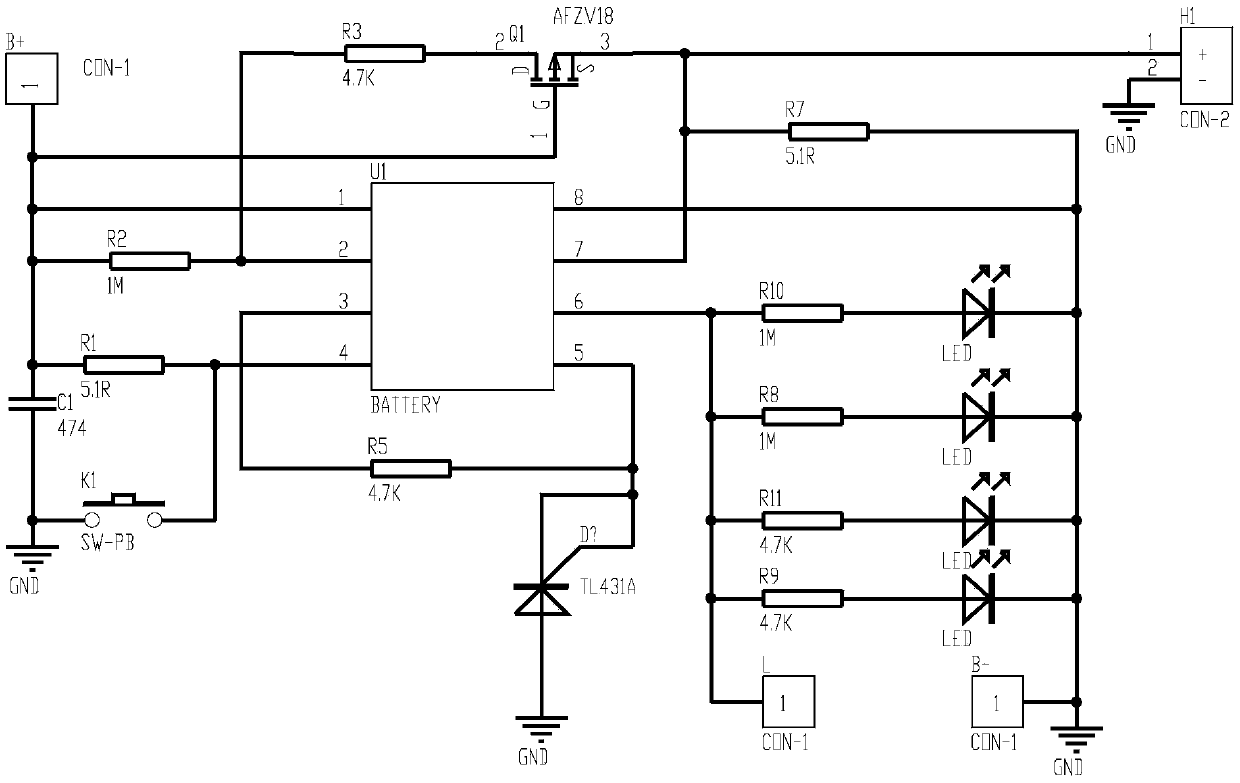

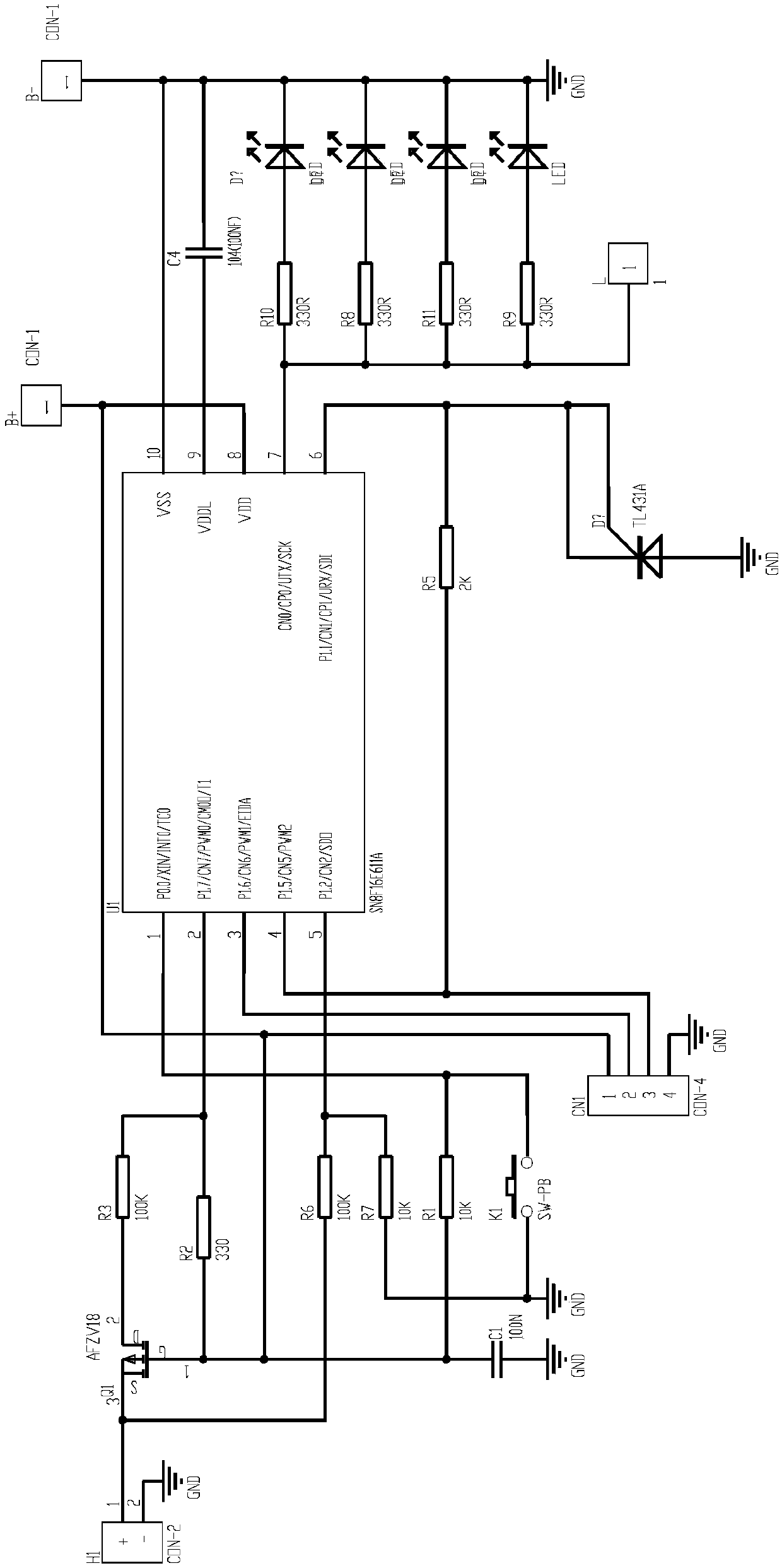

[0019] see Figure 1 to Figure 4 , an electronic cigarette heating element, an electronic cigarette heating element, including a sheet-shaped substrate 1 and a heating element 2 arranged on the surface of the substrate 1; also includes a temperature sensor 3 arranged on the surface of the substrate 1, the surface of the temperature sensor 3 Covered with a protective heat-conducting layer (not shown in the figure), the material of the heat-conducting layer has a temperature resistance of ≥250°C; during the heating process of the heating element of the electronic cigarette, the change in resistance value of the heating resistance X≤50%; the change in resistance value X =|(R1-R2) / R1|, where R1 is the resistance value of the heating element after the temperature rises, R2 is the resistance value of the heating element at room temperature, the room temperature refers to the environment of 20℃-28℃, the heating element and the electronic The smoke control circuit board (not marked in...

Embodiment 2

[0026] The main difference between this embodiment and Embodiment 1 is that the temperature sensor is an independent temperature sensor, which is fixed on the surface of the substrate by welding or a fixed structure, wherein the temperature sensor is placed on the surface of the substrate opposite to the heating element On one side; preferably, the temperature sensor is arranged along the insertion track of the substrate. Other technical features of this embodiment are the same as those of Embodiment 1, and will not be described in detail here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com