A kind of brushless motor stator surplus palm oil protection and cleaning method

A brushless motor, palm oil technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as motor jamming, achieve easy cleaning, solve jamming, and ensure normal operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

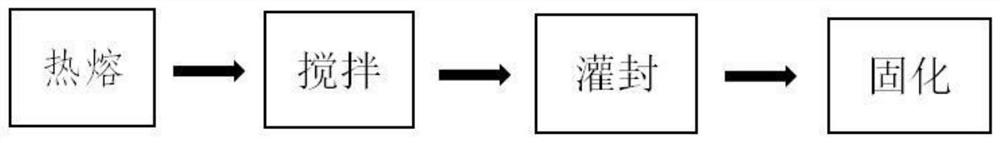

[0034] A method for protecting brushless motor stator excess palm oil, the protection adopts palm oil potting, and the palm oil potting includes the following steps:

[0035] (1) Hot melting: heating the palm oil to melt two-thirds of the palm oil, and stirring the palm oil with a clean stirring rod to make it appear uniform milky white and thick; the heating is to heat the palm oil to 60°C;

[0036] (2) Potting: Potting the palm oil in step (1) into the interior of the stator of the brushless motor, standing for curing, and the potting and sealing process is completed; the time for standing and curing is 25 minutes.

[0037] A cleaning method for brushless motor stator excess palm oil protection, comprising the following steps:

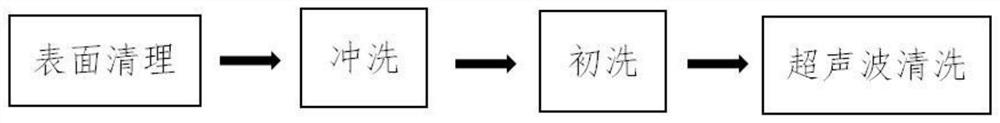

[0038] ①Surface cleaning: Wipe the inner hole of the stator, take out the metal chips embedded in the surface of the grease layer by the lathe, and clean up the excess debris on the surface of the stator of the brushless motor; the method of wiping i...

Embodiment 2

[0044] A method for protecting brushless motor stator excess palm oil, the protection adopts palm oil potting, and the palm oil potting includes the following steps:

[0045] (1) Hot melting: heating the palm oil to melt two-thirds of the palm oil, and stirring the palm oil with a clean stirring rod to make it appear uniform milky white and thick; the heating is to heat the palm oil to 75°C;

[0046] (2) Potting: Potting the palm oil in step (1) into the interior of the stator of the brushless motor, standing for curing, and the potting and sealing process is completed; the time for standing and curing is 35 minutes.

[0047] A cleaning method for brushless motor stator excess palm oil protection, comprising the following steps:

[0048]①Surface cleaning: Wipe the inner hole of the stator, take out the metal chips embedded in the surface of the grease layer by the lathe, and clean up the excess debris on the surface of the stator of the brushless motor; the method of wiping is...

Embodiment 3

[0054] A method for protecting brushless motor stator excess palm oil, the protection adopts palm oil potting, and the palm oil potting includes the following steps:

[0055] (1) Hot melt: heat the palm oil to melt two-thirds of the palm oil, and stir the palm oil with a clean stirring rod to make it appear uniform milky white and thick; the heating is to heat the palm oil to 65°C;

[0056] (2) Potting: Potting the palm oil in step (1) into the interior of the stator of the brushless motor, standing for curing, and the potting and sealing process is completed; the time for standing and curing is 26 minutes.

[0057] A cleaning method for brushless motor stator excess palm oil protection, comprising the following steps:

[0058] ①Surface cleaning: Wipe the inner hole of the stator, take out the metal chips embedded in the surface of the grease layer by the lathe, and clean up the excess debris on the surface of the stator of the brushless motor; the method of wiping is: use a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com