Full-band ship cabin noise prediction and acoustic optimization design method

An optimized design, full-band technology, applied in ship design, design optimization/simulation, measurement of ultrasonic/sonic/infrasonic waves, etc., can solve the problem of less research on full-band cabin noise forecasting methods and processes, and more research on cabin noise forecasting and other problems, to achieve the effect of improving computational efficiency, computational accuracy, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] This embodiment provides a method for cabin noise prediction and acoustic optimization design in the full frequency band of a ship, including the following steps:

[0070] Step S1, setting the frequency range of the ship cabin noise forecast to 1 / 3 octave 20-8000Hz;

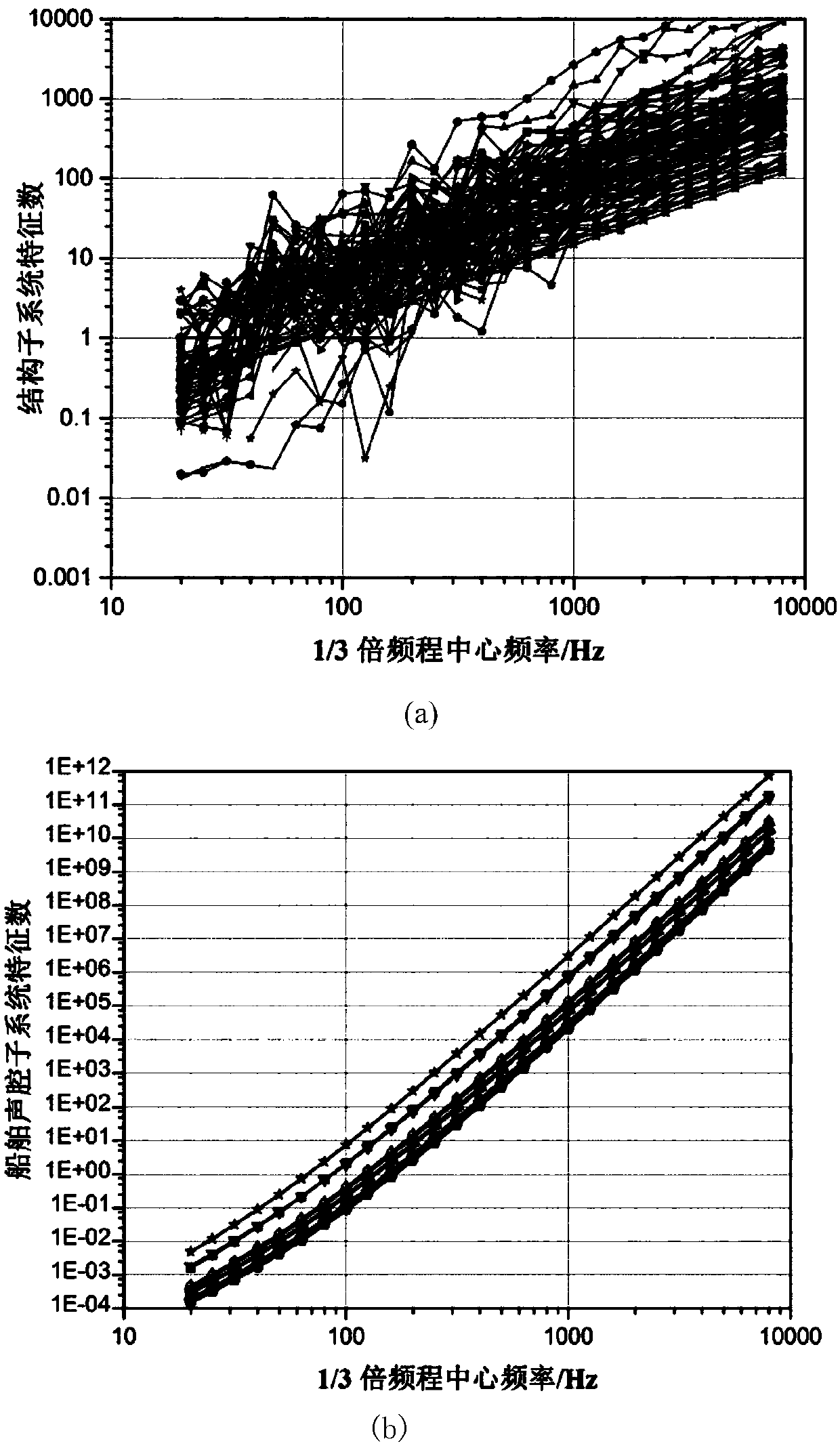

[0071] Step S2. Propose the characteristic number used to characterize the degree of modal density per unit wavelength as the frequency interval division standard, calculate the characteristic number according to the geometric and physical properties of the hull structure and the acoustic cavity, and perform low, medium, and low analysis frequency bands based on the characteristic number. high-frequency division;

[0072] Step S3, according to the size of the characteristic number and the structural characteristics of the ship, respectively establish the low, medium and high frequency cabin noise prediction models of the ship;

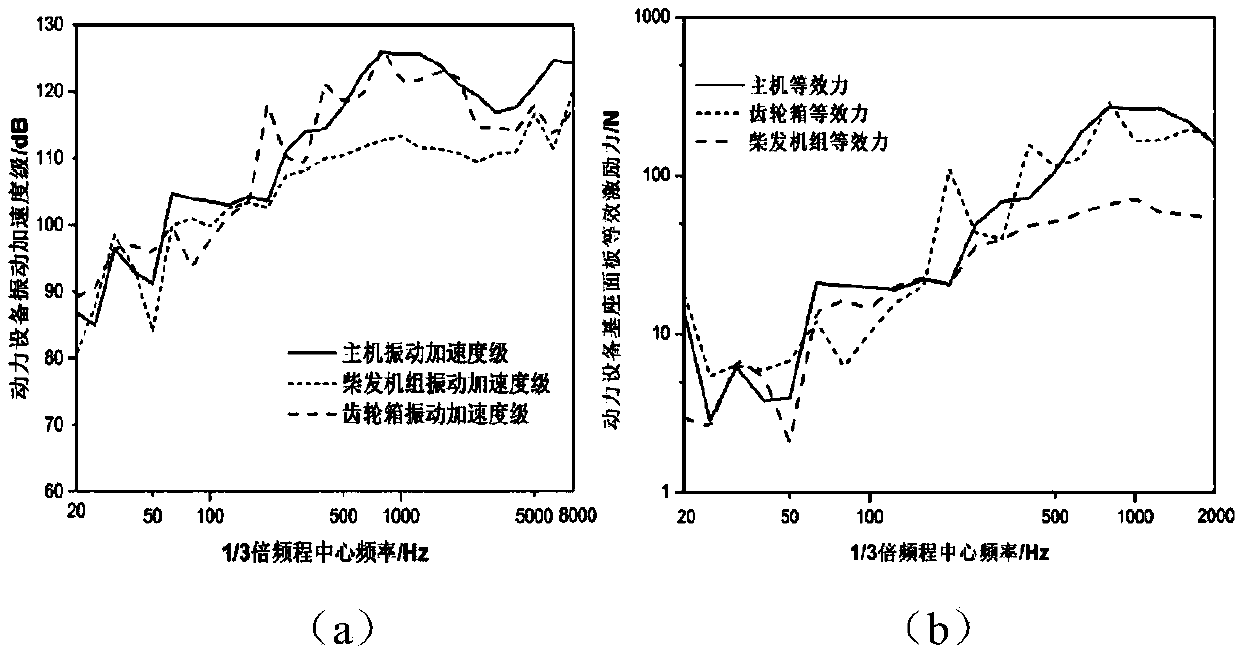

[0073] Step S4, obtain main power equipment structural noise and air noise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com