A pod-type full-turn ship electric propulsion system

An electric propulsion and pod-type technology, which is applied in the direction of ship propulsion, rotary propeller, propulsion components, etc., can solve the problems that the diameter of the propeller cannot be changed, the propulsion cannot be obtained, and the propeller cannot reach the speed of the ship. The effect of ship maneuverability, improvement of propeller efficiency, and reduction of electricity cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

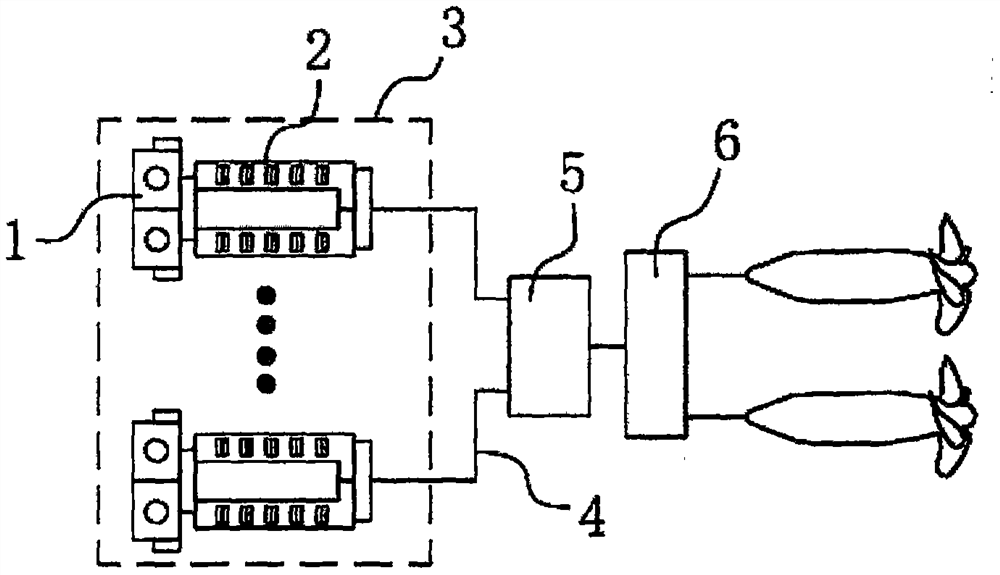

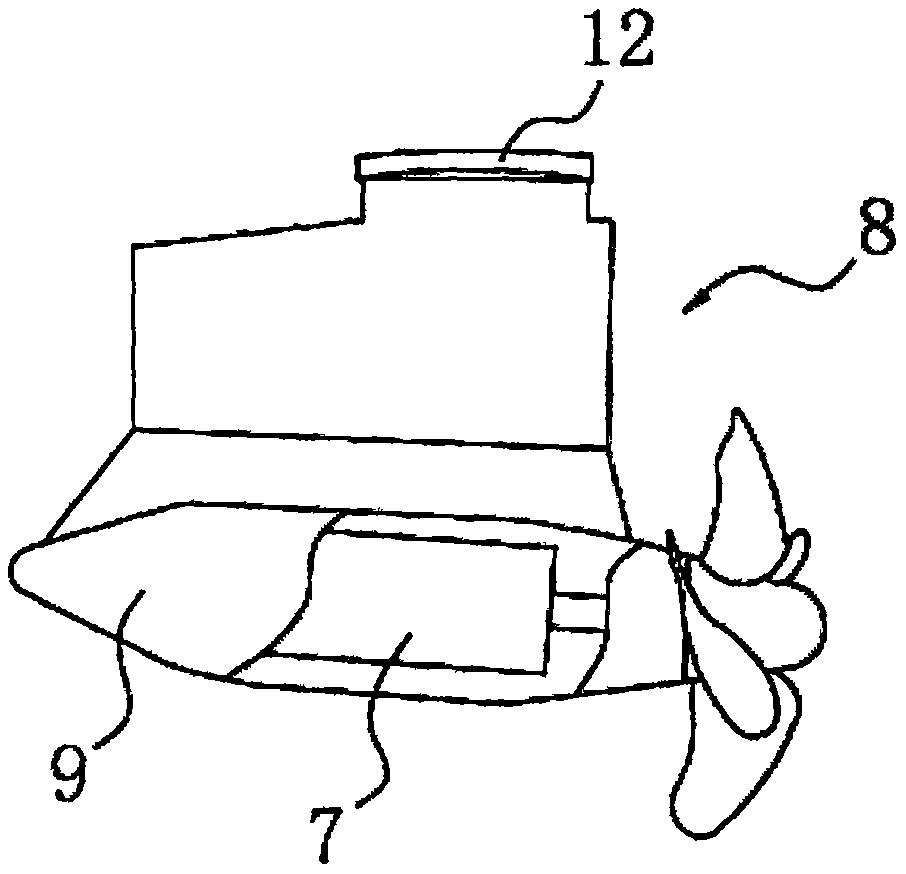

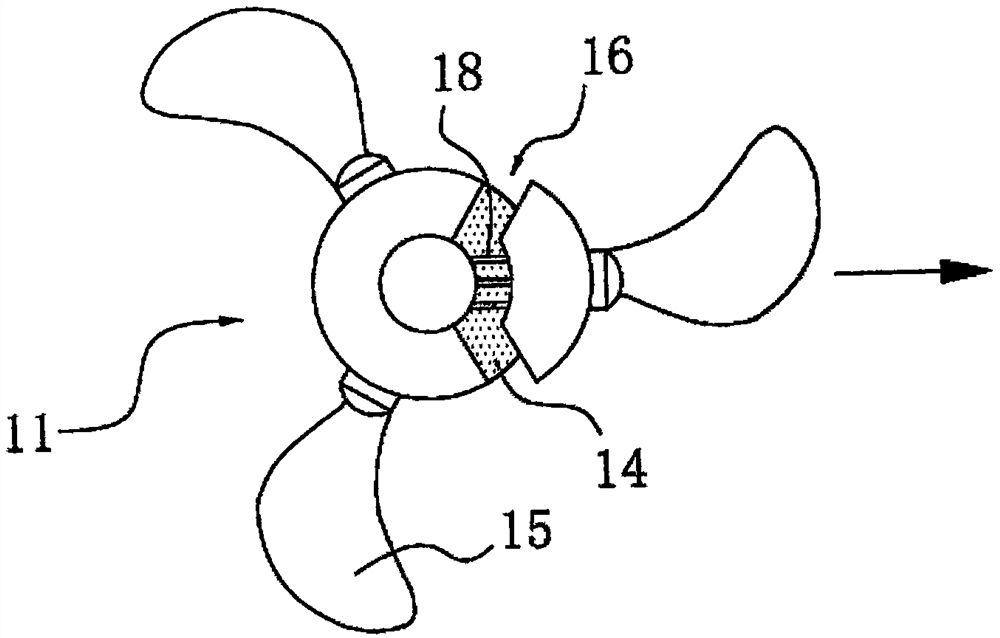

[0021] Such as figure 1 , 2 , 3, 4, and 5, a pod-type full-turn ship electric propulsion system includes at least one group of power generation units 3 composed of a prime mover 1 and a generator set 2 connected to the prime mover 1. In this application, the prime mover 1 is a diesel engine. The diesel engine on board is not used as the main propulsion device, but as the prime mover for generating electricity to drive the motor to generate electricity. They are usually several four-stroke medium-speed diesel engines of the same model and output power. A ship using an all-electric propulsion system can arbitrarily adjust the number of operating generator sets 2 according to changes in the ship's speed, displacement, and electrical load on the ship, so as to maintain high-efficiency operation and reduce fuel consumption. good economy.

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com