Composite structure film based on double-gradient tapered hole array, and preparation method thereof

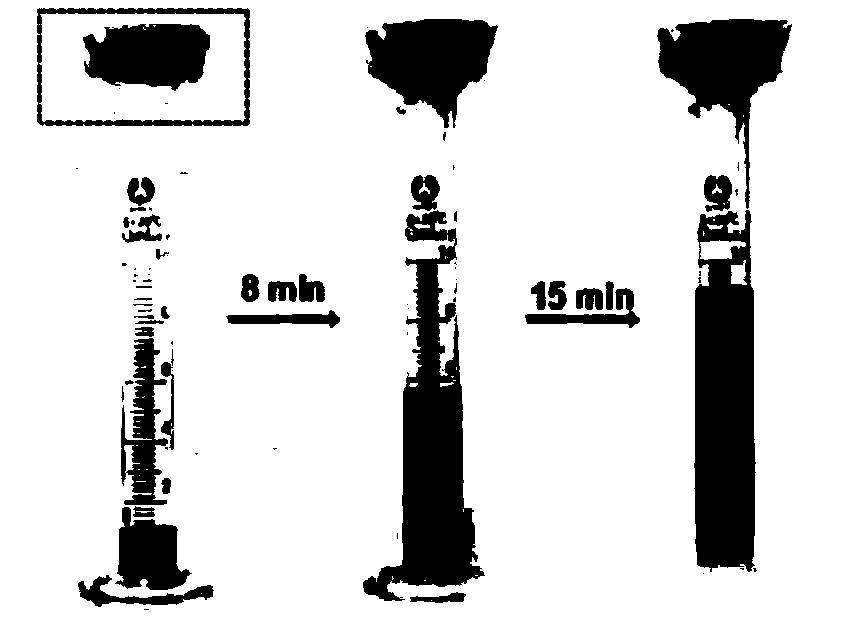

A composite structure and tapered hole technology, applied in the field of composite structure membrane and its preparation, can solve the problems of single self-driving energy source, unsatisfactory self-driving effect of water droplets in water mist collection membrane, etc., and achieve the goal of increasing the mist water collection rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

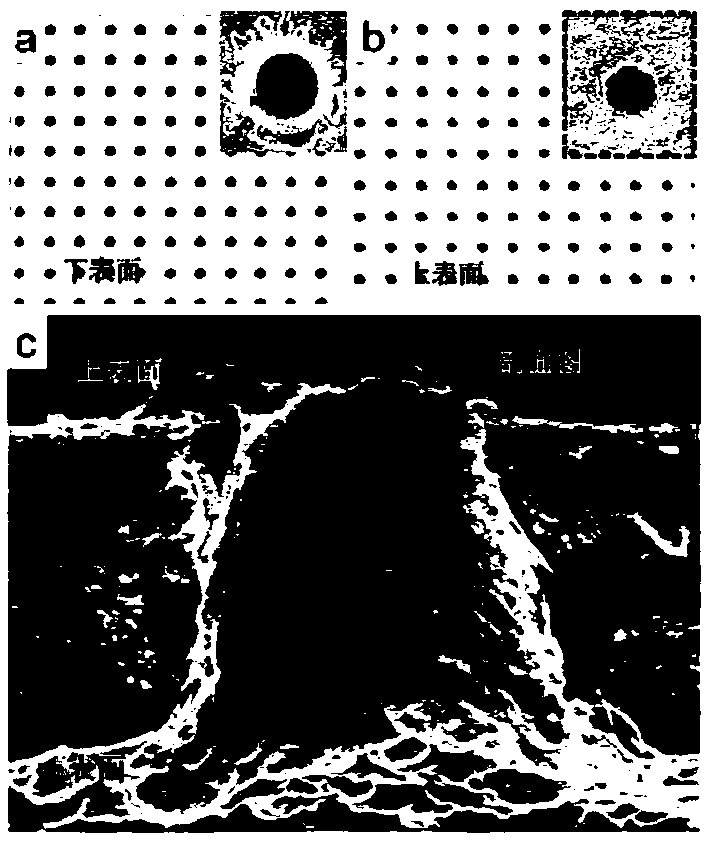

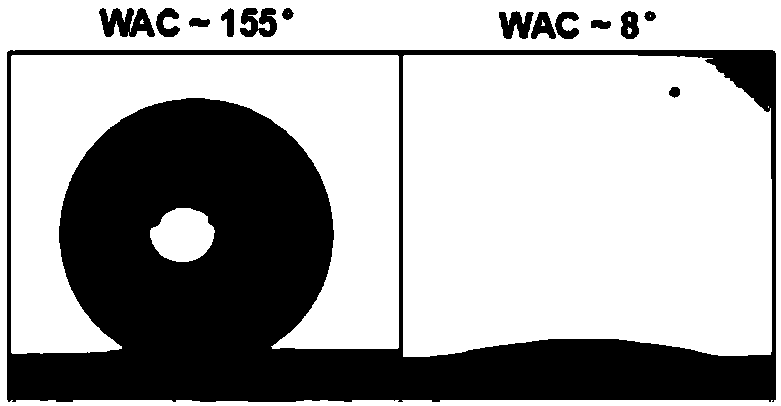

[0019] Specific implementation mode 1: A composite structure membrane based on a double-gradient tapered hole array in this embodiment, the composite structure membrane is an aluminum foil membrane, and there are tapered holes on the aluminum foil membrane, and the cross-section of the tapered holes is equal to Side trapezoidal, the hole radius of the tapered hole gradually increases from the upper surface to the lower surface of the aluminum foil membrane, and the upper surface of the aluminum foil membrane has a low surface energy material C 10 h 4 Cl 3 f 17 Si, the lower surface material is Al 2 o 3 .

specific Embodiment approach 2

[0020] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the nanoparticles on the inner wall of the tapered hole gradually increase from the upper surface to the lower surface of the aluminum foil film, C 10 h 4 Cl 3 f 17 The composition ratio of Si material decreases gradually. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 in that: the upper surface of the tapered hole has a rough structure, and the lower surface of the tapered hole has a petal-shaped rough structure. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com