Device and method for accelerating evaporation of acid in-situ leaching uranium mining evaporation pond waste liquid

A technology of in-situ leaching for uranium mining and evaporation pools, which is applied in mining wastewater treatment, heating water/sewage treatment, radioactive pollutants, etc., can solve problems such as high risk of leakage, damage to surface vegetation, and difficulty in surface restoration, achieving savings Effects of construction cost, reduced footprint, and faster evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

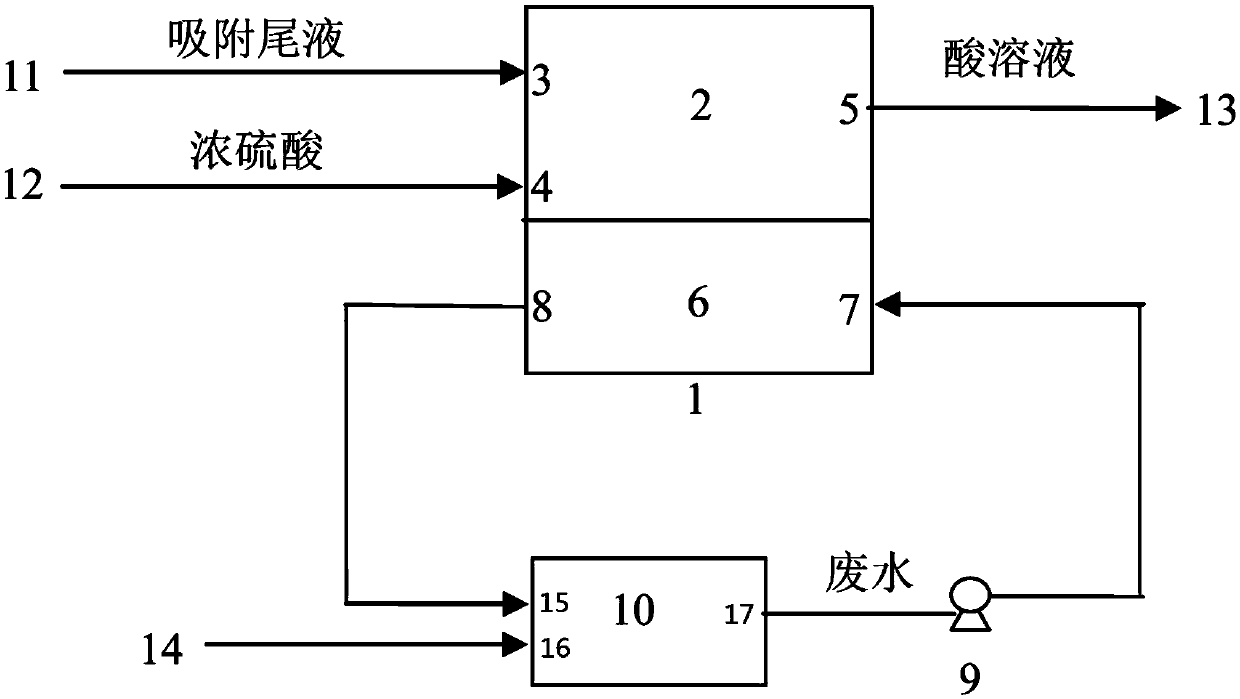

Embodiment 1

[0042] In a uranium mine in Inner Mongolia, the average annual evaporation is 2449mm, and the average annual rainfall is 185mm. The uranium leaching unit is 1 pumping and 4 injections, and the pumping volume is 10m after reaching the pumping balance. 3 / h, leachate pH=2.0, dosing liquid sulfuric acid concentration is 10g / L, adopts the acid method ground leaching mining uranium of the present invention to utilize the concentrated sulfuric acid dilution exothermic method to accelerate waste water evaporation and comprise the following steps:

[0043] 1) 92.5% industrial sulfuric acid and adsorption tail liquid from the sulfuric acid storage tank are passed into the mixing chamber of the graphite heat exchanger, the sulfuric acid flow rate is 100kg / h, the adsorption tail liquid flow rate is 200L / h, and the system temperature is 20°C. After dilution, the temperature of the sulfuric acid solution rose to 71°C.

[0044] 2) The diluted sulfuric acid solution flows into the liquid mix...

Embodiment 2

[0050] In an acid leaching uranium mine in Inner Mongolia, the average annual evaporation is 1849mm, the average annual rainfall is 175mm, and the leaching unit has 2 pumps and 6 injections, and the pumping volume is 24m after the pumping balance is reached. 3 / h, the remaining acid in the leachate is 1g / L, and the sulfuric acid concentration of the dosing solution is 8g / L, adopting the acid method ground leaching mining uranium of the present invention utilizes the concentrated sulfuric acid dilution exothermic method to accelerate the waste water evaporation and comprises the following steps:

[0051] 1) 92.5% industrial sulfuric acid and adsorption tail liquid from the sulfuric acid storage tank are passed into the mixing chamber of the graphite heat exchanger, the sulfuric acid flow rate is 170kg / h, and the adsorption tail liquid flow rate is 170L / h. The system temperature is 10°C. After dilution, the temperature of the sulfuric acid solution rises to 80°C.

[0052] 2) Th...

Embodiment 3

[0058] In an acid leaching uranium mine in Xinjiang, the average annual evaporation is 2102 mm, the average annual rainfall is 120 mm, and the leaching unit has 6 pumps and 12 injections, and the pumping volume is 70 m after reaching the pumping balance. 3 / h, the remaining acid in the leachate is 2g / L, and the sulfuric acid concentration of the dosing solution is 5g / L, adopting the acid method ground leaching mining uranium of the present invention utilizes the concentrated sulfuric acid dilution exothermic method to accelerate the waste water evaporation and comprises the following steps:

[0059] 1) 92.5% industrial sulfuric acid and adsorption tail liquid from the sulfuric acid storage tank are passed into the graphite heat exchanger mixing chamber, the flow rate of sulfuric acid is 210kg / h, and the flow rate of adsorption tail liquid is 210L / h. The system temperature is 15°C. After dilution, the temperature of the sulfuric acid solution rises to 80°C.

[0060] 2) The dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com