Water based UV high-fullness high-transparency clear primer and preparation method and application thereof

A clear primer, water-based technology, used in primers, polyurea/polyurethane coatings, coatings, etc., can solve the problem of reduced transparency of recoating, achieve excellent transparency, short drying and curing time, and improve the effect of solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

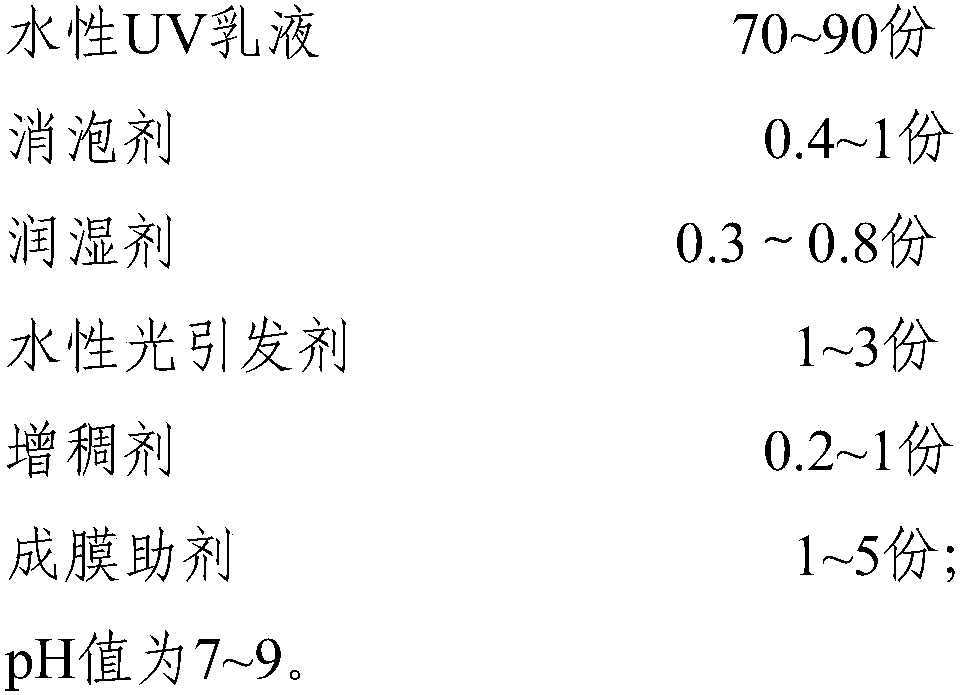

[0048] This embodiment provides a water-based UV high-volume and high-transparency primer, which consists of the following components:

[0049]

Embodiment 2

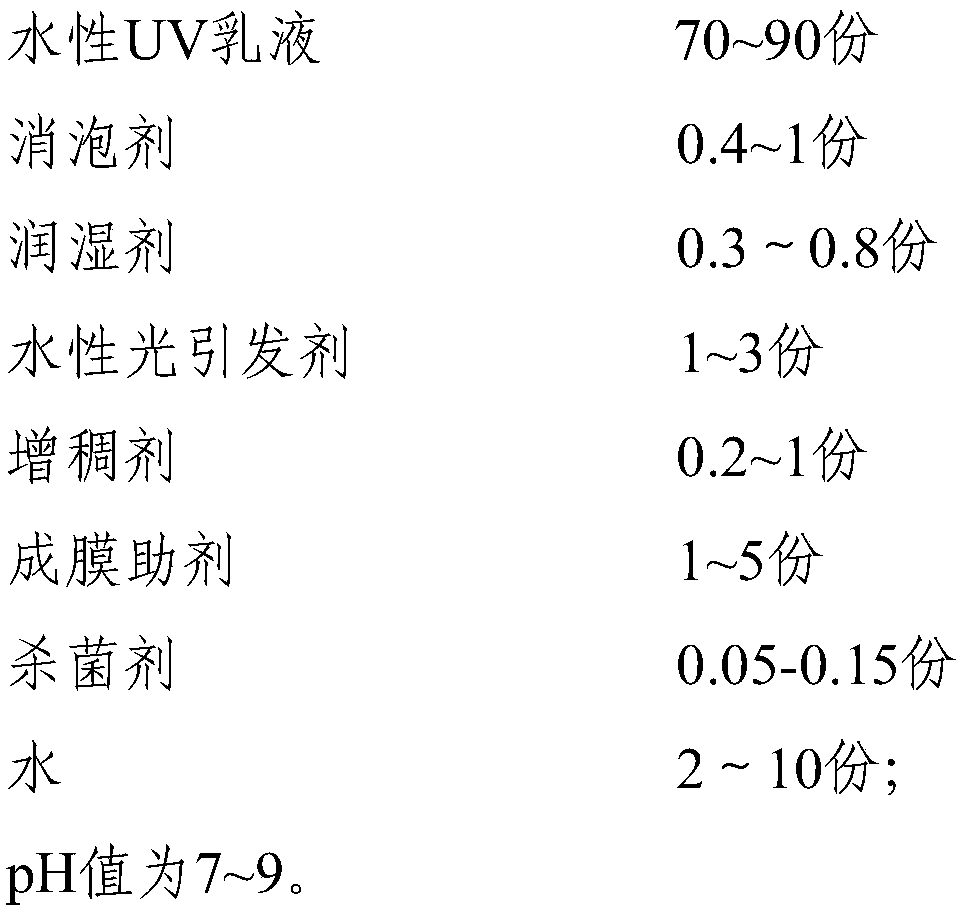

[0051] This embodiment provides a water-based UV high-volume and high-transparency primer, which consists of the following components:

[0052]

Embodiment 3

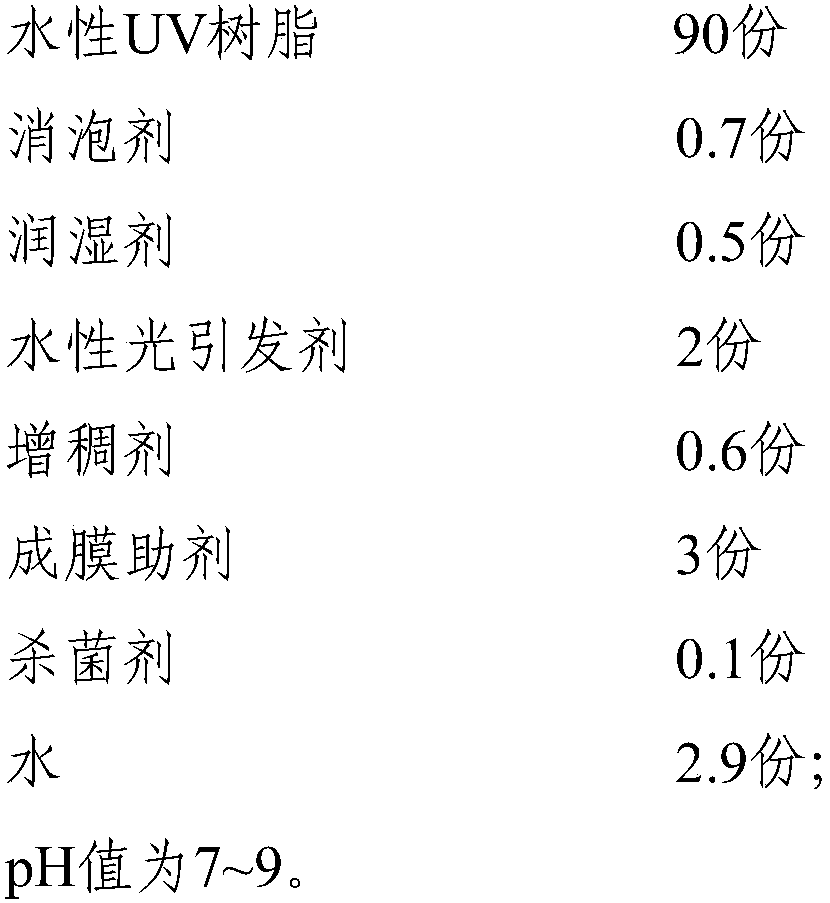

[0054] This embodiment provides a water-based UV high-volume and high-transparency primer, which consists of the following components:

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com