Preparation method of polyglycerol fatty acid ester

A fatty acid ester and polyglycerol technology, which is applied in the direction of fatty acid esterification, can solve the problems affecting the application of polyglycerol fatty acid ester, the poor quality of polyglycerol fatty acid ester products, and the poor quality of polyglycerol, so as to achieve easy large-scale Industrial production, low production cost, strong emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

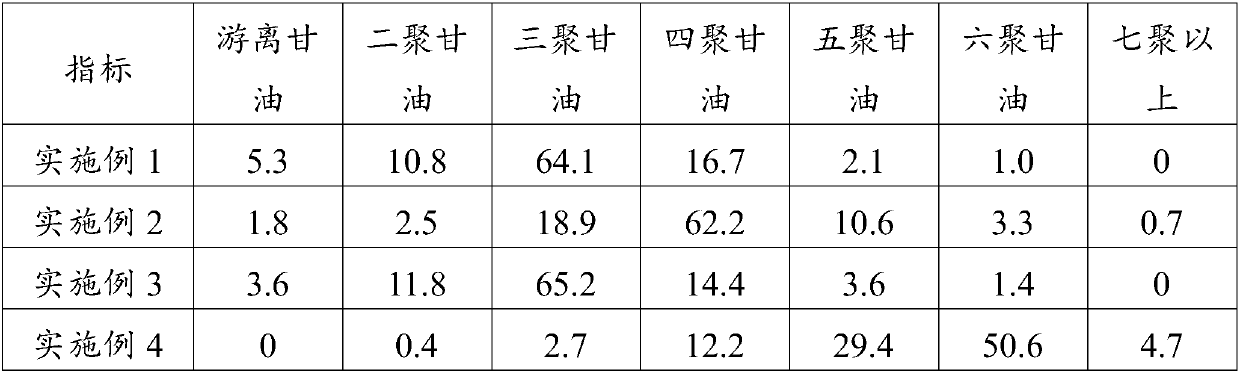

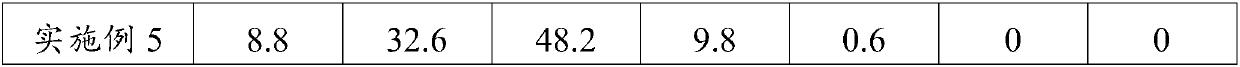

Examples

Embodiment 1

[0025] A preparation method of polyglycerol fatty acid ester, comprising the following steps:

[0026] (1) Add 500kg glycerin to the reaction kettle, start stirring, heat to 150°C under the condition of vacuum degree of 0.05MPa, then add 2kg KF-SnCl 2 / Al 2 o 3 Supported solid base catalyst, continue to heat up to 230 ° C, heat preservation reaction for 2 hours and 45 minutes to prepare mixed polyglycerol;

[0027] (2) Add the mixed polyglycerol to the cooling tank, start stirring, cool down to 160°C, filter and add to the storage tank, and then add molecular distillation equipment for molecular distillation, wherein the first-stage molecular distillation controls the temperature at 170°C, and the vacuum degree is 10Pa; The secondary molecular distillation controlled the temperature at 210°C and the vacuum at 5Pa, collected the distilled polyglycerol, and obtained 390kg of triglycerol;

[0028] (3) According to stearic acid: polyglycerol (molar ratio) = 1.3:1, heat 600kg of...

Embodiment 2

[0032] A preparation method of polyglycerol fatty acid ester, comprising the following steps:

[0033] (1) Add 500kg glycerin to the reaction kettle, start stirring, heat to 140°C under the condition of vacuum degree of 0.06MPa, then add 2kg KF-SnCl 2 / Al 2 o 3 Supported solid base catalyst, heating up to 240°C, heat preservation reaction for 4 hours to prepare mixed polyglycerol;

[0034](2) Add the mixed polyglycerol to the cooling tank, start stirring, cool down to 160°C, filter and add to the storage tank, and then add molecular distillation equipment for molecular distillation, wherein the first-stage molecular distillation controls the temperature at 195°C, and the vacuum degree is 5Pa; The temperature of the secondary molecular distillation is controlled at 220°C and the vacuum degree is 1Pa, and the distilled polyglycerol is collected to obtain 395kg of tetrapolyglycerol;

[0035] (3) According to stearic acid: polyglycerol (molar ratio) = 1.3:1, heat 460kg of stear...

Embodiment 3

[0038] A preparation method of polyglycerol fatty acid ester, comprising the following steps:

[0039] (1) Add 500kg glycerin to the reaction kettle, start stirring, heat to 180°C under the condition of vacuum degree of 0.07MPa, then add 1.5kg KF-SnCl 2 / Al 2 o 3 Supported solid base catalyst, continue to heat up to 230 ° C, heat preservation reaction for 2 hours and 45 minutes to prepare mixed polyglycerol;

[0040] (2) Add the mixed polyglycerol to the cooling tank, start stirring, cool down to 150°C, then filter and add to the storage tank, and then add molecular distillation equipment for molecular distillation, in which the first-stage molecular distillation controls the temperature at 170°C and the vacuum degree is 30Pa ; Secondary molecular distillation control temperature is 210 ℃, vacuum degree is 3Pa, collects the distilled polyglycerol, obtains tripolyglycerol 394kg;

[0041] (3) According to oleic acid:polyglycerol (molar ratio)=1.3:1, 600kg oleic acid is added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com