Preparation method of self-cleaning fabric

A self-cleaning, fabric technology, applied in fiber types, textiles and papermaking, fiber processing, etc., can solve problems such as harm to the human body and the environment, decreased air permeability, affecting the feel of clothing, etc. The effect of promoting prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

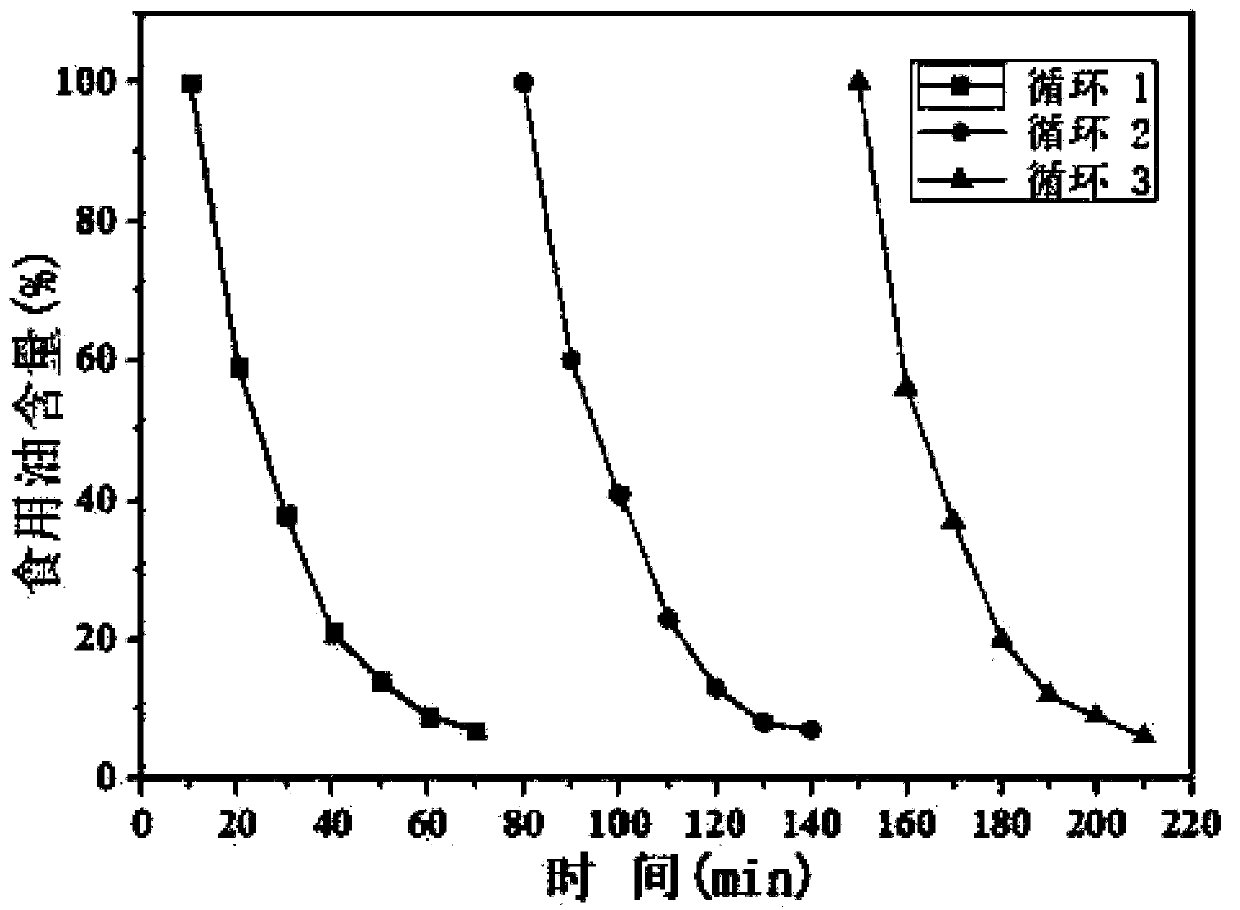

Image

Examples

Embodiment 1

[0026] A method for preparing a self-cleaning fabric, comprising the steps of:

[0027] (1) 2,2'-diimidazole biphenyl: zinc nitrate hexahydrate = 1:1, add to 5% sodium dihydrogen phosphate aqueous solution, the concentration of zinc nitrate hexahydrate is 1%, stir to obtain a mixed solution;

[0028] (2) The mixture was ultrasonically oscillated at 40°C for 4 hours, cooled to room temperature and then filtered. The filtered product was dispersed in isopropanol and ultrasonically oscillated at 40°C for 4 hours. same;

[0029] (3) After the shaking is over, filter, wash the filtrate with saturated aqueous sodium chloride solution, and dry to obtain the product, which is mixed with TiO 2 1:1 mixed evenly;

[0030] (4) Using sodium hexametaphosphate: polyethylene glycol: sodium polyacrylate at a ratio of 1:1:1 as a composite dispersant, 2,2'-diimidazole biphenyl zinc / TiO 2 : Composite dispersant is dispersed in water at 1:1, in which, 2,2'-diimidazole biphenyl zinc / TiO 2 The m...

Embodiment 2

[0033] A method for preparing a self-cleaning fabric, comprising the steps of:

[0034] (1) 2,2'-diimidazole biphenyl: Add zinc nitrate hexahydrate = 2:1 into 5% aqueous solution of sodium dihydrogen phosphate, the concentration of zinc nitrate hexahydrate is 2%, stir to obtain a mixed solution;

[0035] (2) The mixture was ultrasonically oscillated at 50°C for 5 hours, cooled to room temperature and then filtered. The filtered product was dispersed in isopropanol and ultrasonically oscillated at 50°C for 5 hours. same;

[0036] (3) After the shaking is over, filter, wash the filtrate with saturated aqueous sodium chloride solution, and dry to obtain the product, which is mixed with TiO 2 2:1 mixed evenly;

[0037] (4) With sodium hexametaphosphate: polyethylene glycol: sodium polyacrylate = 1:1:1 as a composite dispersant, 2,2'-diimidazole biphenyl zinc / TiO 2 : Composite dispersant = 2:1 dispersed in water, where 2,2'-diimidazole biphenyl zinc / TiO 2 The mass fraction is 4...

Embodiment 3

[0040] A method for preparing a self-cleaning fabric, comprising the steps of:

[0041] (1) Add 2,2'-diimidazole biphenyl: zinc nitrate hexahydrate = 3:1 into 5% aqueous solution of sodium dihydrogen phosphate, the concentration of zinc nitrate hexahydrate is 2%, stir to obtain a mixed solution;

[0042] (2) The mixture was ultrasonically oscillated at 60°C for 6 hours, cooled to room temperature and then filtered. The filtered product was dispersed in isopropanol and ultrasonically oscillated at 60°C for 6 hours. same;

[0043] (3) After the shaking is over, filter, wash the filtrate with saturated aqueous sodium chloride solution, and dry to obtain the product, which is mixed with TiO 2 3:1 mixed evenly;

[0044] (4) With sodium hexametaphosphate: polyethylene glycol: sodium polyacrylate = 1:1:1 as a composite dispersant, 2,2'-diimidazole biphenyl zinc / TiO 2 : Composite dispersant = 3:1 dispersed in water, in which 2,2'-diimidazole biphenyl zinc / TiO 2 The mass fraction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com