Rotary supporting frame for gearbox box cover and passivating production line

A gearbox and support frame technology, applied in metal material coating process, transmission parts, belt/chain/gear, etc., can solve the problems of complicated process, no production equipment, long intermediate turnover period, etc., and achieve standardized operation procedures , prevent loss of function, and arrange the effect reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

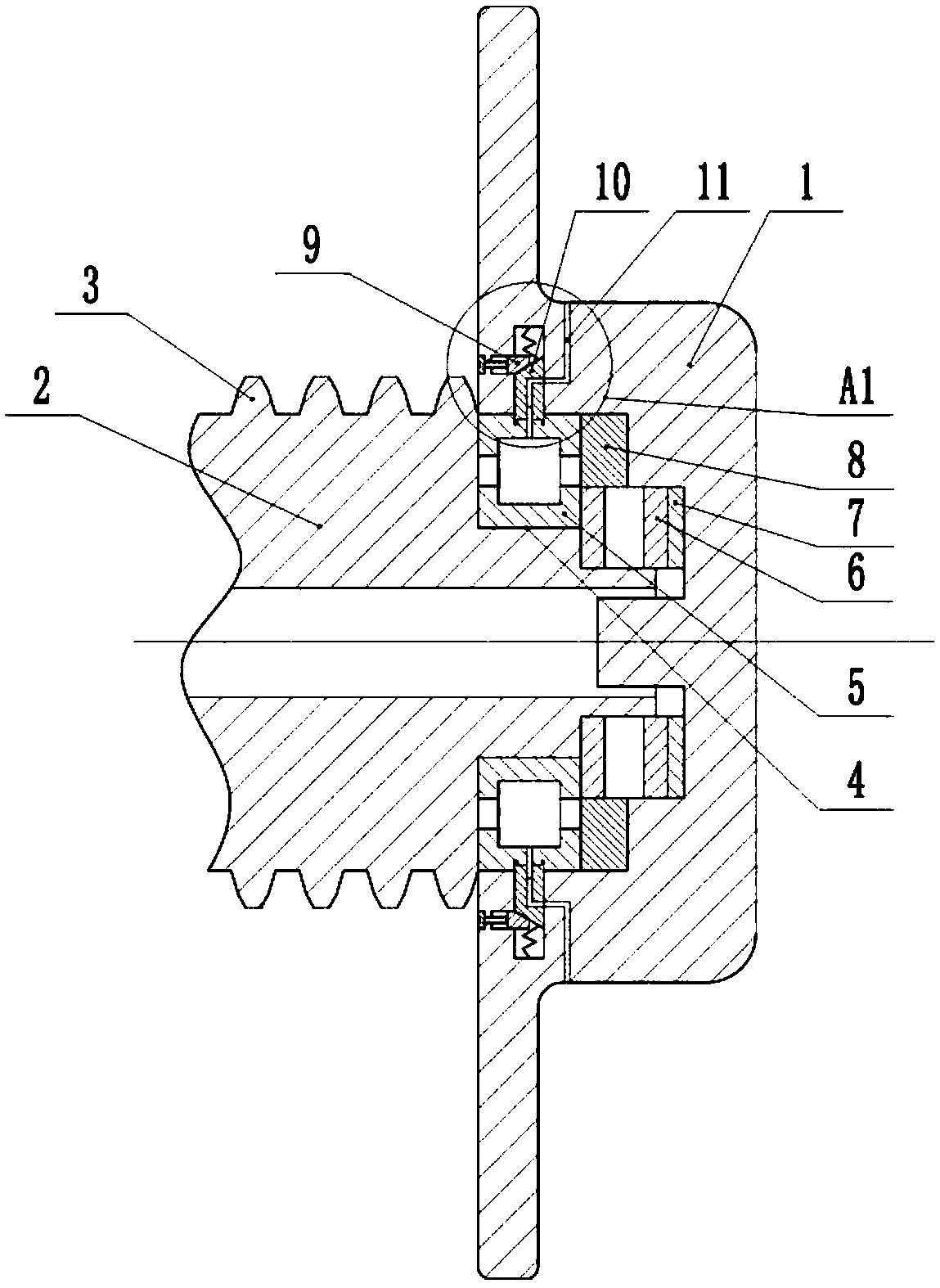

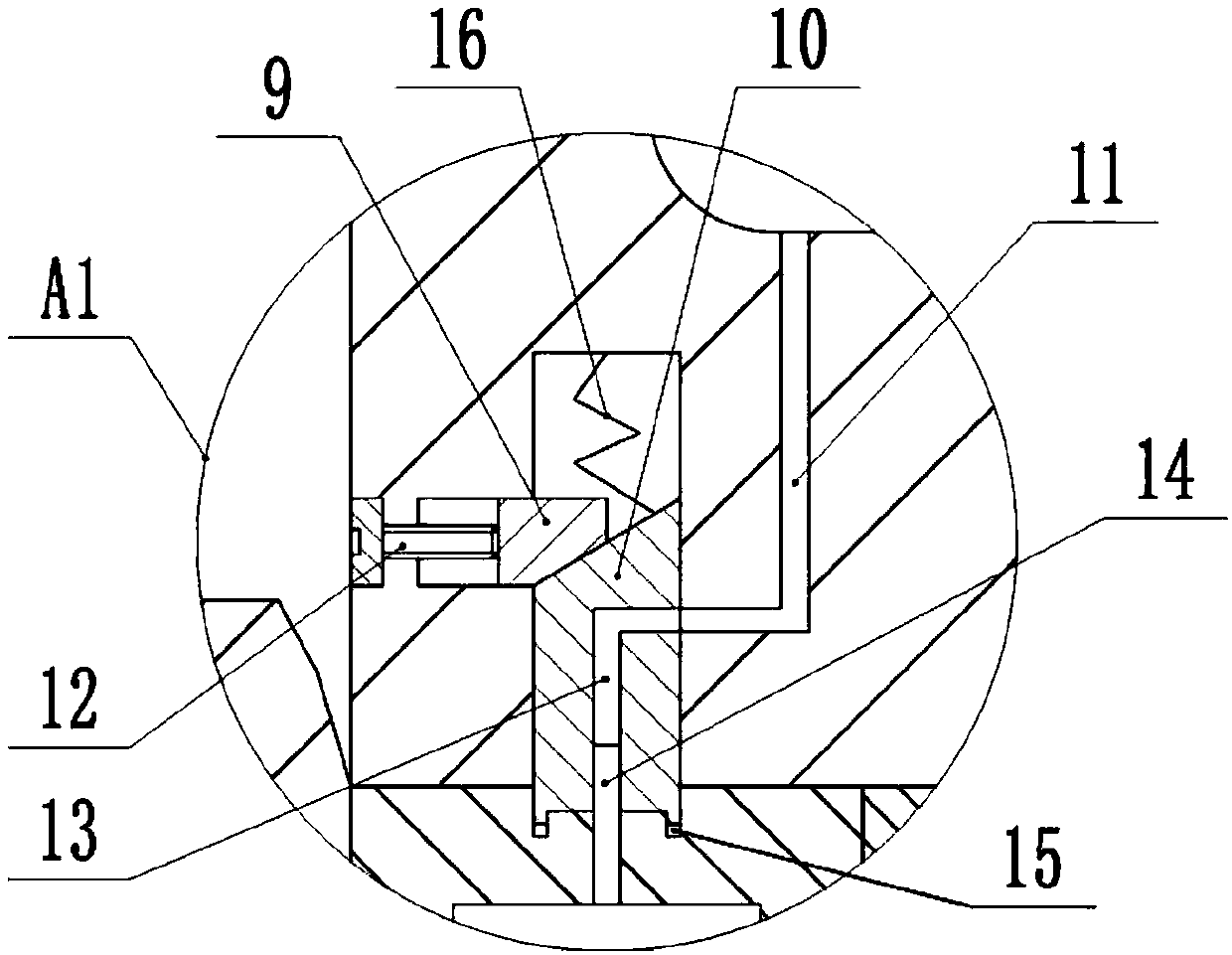

[0022] as attached figure 1 And attached figure 2 As shown, the rotating support frame of the transmission case cover includes a thrust bearing 6 and a radial bearing arranged sequentially from the inside to the outside. Preferably, the radial bearing is a cylindrical roller bearing 5, and the shaft ring of the thrust bearing 6 is sleeved on the At the end of the output shaft 2, the seat ring of the thrust bearing 6 is arranged on the supporting frame body 1, and an adjusting gasket 7 is arranged between the seat ring of the thrust bearing 6 and the supporting frame body 1 of the gearbox.

[0023] The inner ring of the radial bearing is set on the shoulder 4 of the output shaft 2, the left side of the inner ring of the radial bearing is in contact with the output gear 3 of the output shaft 2, and the right side of the inner ring of the radial bearing is in contact with the thrust bearing The shaft rings of 6 are against each other, and a gasket 8 is arranged between the inne...

Embodiment 2

[0028] The passivation production line of the rotating support frame of the gearbox case cover arranges the incoming material inspection workbench, pickling equipment, washing liquid tank, testing platform and drying equipment in sequence according to the process, and the equipment is connected by a transmission roller. The pickling equipment adopts a pickling liquid tank, and the workpiece is dipped to remove the oxide layer. The upper part of the pickling liquid tank is equipped with a liquid inlet pipe, and the side wall of the tank body is equipped with a liquid discharge pipe. The liquid inlet pipes are respectively connected to the pickling liquid source. The liquid outlet pipe is connected to the liquid discharge device, and the pickling liquid is recycled.

Embodiment 3

[0030] The passivation production line of the rotating support frame of the gearbox case cover arranges the incoming material inspection workbench, pickling equipment, washing liquid tank, testing platform and drying equipment in sequence according to the process, and the equipment is connected by a transmission roller. The pickling equipment adopts a spraying machine, and the lower part of the spraying machine is equipped with a liquid receiving tank, and the workpiece is sprayed with pickling passivation paste to remove the oxide layer.

[0031]When adopting embodiment 2 or embodiment 3 production line to clean, press incoming material inspection--spray (rolling brush) passivation solution-clean water flushing-check-drying operation, at first on the incoming material inspection workbench All incoming materials are inspected to ensure that the rotating support frame should be free from welding slag, cracks, severe scratches and other mechanical damages, so as to meet the pickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com