Preparation method of nitrogen-containing porous carbon/manganese dioxide nanowire composite electrode

A manganese dioxide nano-composite electrode technology, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., to achieve the effect of rich raw materials, simple operation, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

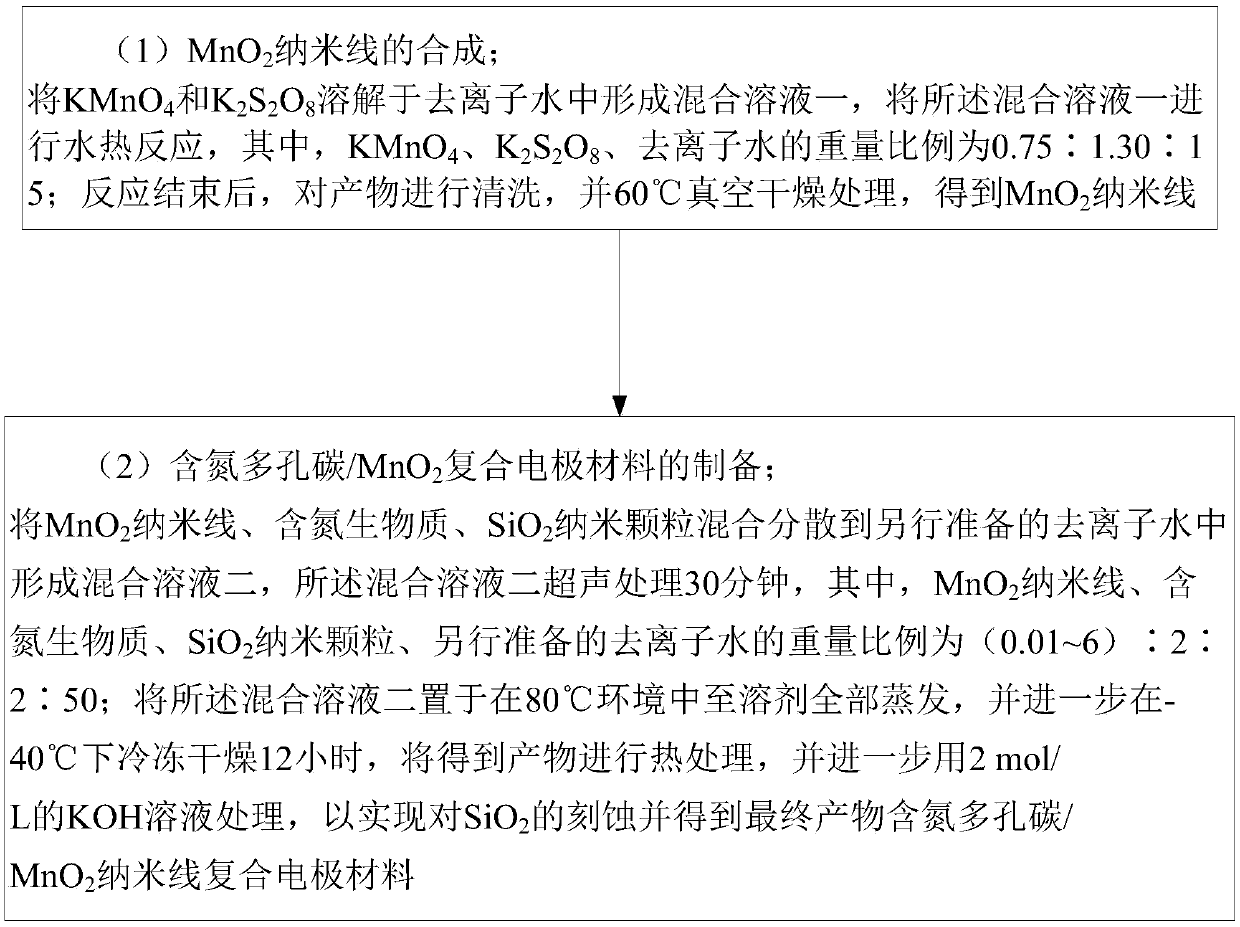

Method used

Image

Examples

Embodiment 1

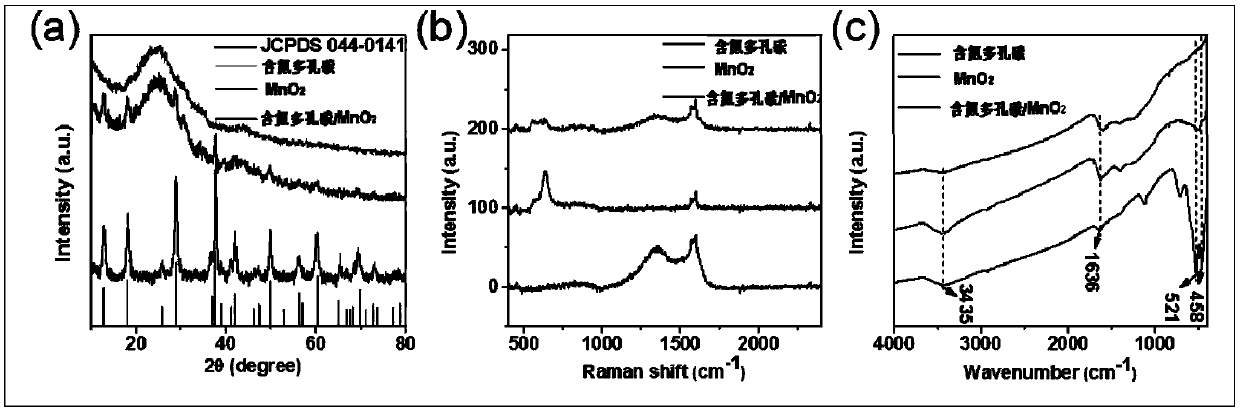

[0040] 0.75 g KMnO 4 and 1.30 g K 2 S 2 o 8 Dissolve in 15 mL deionized water. The above-mentioned mixed solution was placed in a reactor for hydrothermal high-temperature reaction, the temperature was 140°C, and the reaction time was 24 hours. After the reaction, the product was washed with deionized water and alcohol, and dried in a vacuum oven at 60°C to obtain MnO 2 Nanowires, the nanowires have a diameter of about 20-25nm and a length of about 1 μm.

[0041] 0.1 gram of MnO prepared by the above reaction 2 Nanowires with 2 grams of gelatin, 2 grams of SiO 2 Nanoparticles (approximately 50 nm in diameter) were mixed and dispersed in 50 ml of deionized water and sonicated for 30 min. After that, the above mixed solution was placed in an oven at 80°C until the solvent was completely evaporated, and further freeze-dried at -40°C for 12 hours. The obtained product was subjected to heat treatment, and the heat treatment conditions were first treated at 300°C for 2 hours...

Embodiment 2

[0044] 0.75 g KMnO 4 and 1.30 g K 2 S 2 o 8 Dissolve in 15 mL deionized water. The above-mentioned mixed solution was placed in a reactor for hydrothermal high-temperature reaction, the temperature was 140°C, and the reaction time was 24 hours. After the reaction, the product was washed with deionized water and alcohol, and dried in a vacuum oven at 60°C to obtain MnO 2 Nanowires, the nanowires have a diameter of about 20-25nm and a length of about 1 μm.

[0045] 0.3 gram of MnO prepared by the above reaction 2 Nanowires with 2 grams of gelatin, 2 grams of SiO 2 Nanoparticles (approximately 50 nm in diameter) were mixed and dispersed in 50 ml of deionized water and sonicated for 30 min. After that, the above mixed solution was placed in an oven at 80°C until the solvent was completely evaporated, and further freeze-dried at -40°C for 12 hours. The obtained product was subjected to heat treatment, and the heat treatment conditions were first treated at 300°C for 2 hours...

Embodiment 3

[0047] 0.75 g KMnO 4 and 1.30 g K 2 S 2 o 8 Dissolve in 15 mL deionized water. The above-mentioned mixed solution was placed in a reactor for hydrothermal high-temperature reaction, the temperature was 140°C, and the reaction time was 24 hours. After the reaction, the product was washed with deionized water and alcohol, and dried in a vacuum oven at 60°C to obtain MnO 2 Nanowires, the nanowires have a diameter of about 20-25nm and a length of about 1 μm.

[0048] 0.5 gram of MnO prepared by the above reaction 2 Nanowires with 2 grams of gelatin, 2 grams of SiO 2Nanoparticles (approximately 50 nm in diameter) were mixed and dispersed in 50 ml of deionized water and sonicated for 30 min. After that, the above mixed solution was placed in an oven at 80°C until the solvent was completely evaporated, and further freeze-dried at -40°C for 12 hours. The obtained product was subjected to heat treatment. The heat treatment conditions were first treated at 300°C for 2 hours, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com