Synthesis method of benzoyl cyanide

A synthesis method, the technology of benzoyl cyanide, applied in the field of synthesis of benzoyl cyanide, can solve the problems of low conversion rate, high risk, difficult operation, etc., and achieve the effect of high conversion rate, simple operation and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

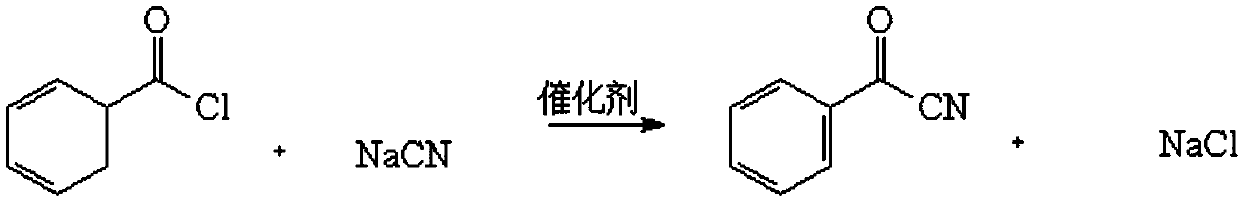

Image

Examples

Embodiment 1

[0014] The synthetic method of embodiment one benzoyl cyanide

[0015] Put 100mL of toluene, 23.7g of 97% solid sodium cyanide, 0.06g of polyethylene glycol 600, 0.06g of trioctylmethylammonium chloride, and 0.1g of water into a 250mL four-necked flask, turn on the tail gas absorption device, stir, Circulating cooling water. Turn on the heating device and start heating. When the temperature of the reaction solution rose to 60°C, the cock of the constant pressure dropping funnel was opened, and 57.4g of benzoyl chloride was added dropwise, keeping the reaction temperature between 60°C and 85°C. The benzoyl chloride was dropped in about 1.5 hours. After the dropwise addition, the reflux reaction was continued and samples were taken to track the reaction process. When the mass fraction of benzoyl chloride in the reaction solution was less than 0.1%, the reaction was over, and it took about 4 hours. After cooling down to 35°C-45°C, filter, wash the filter residue twice with 40mL...

Embodiment 2

[0017] The synthetic method of embodiment dibenzoyl cyanide

[0018] Put 100mL of toluene, 23.7g of 97% solid sodium cyanide, 0.3g of polyethylene glycol 600, 0.3g of trioctylmethylammonium chloride, and 0.6g of water into a 250mL four-necked flask, turn on the tail gas absorption device, stir, Circulating cooling water. Turn on the heating device and start heating. When the temperature of the reaction solution rose to 60°C, the cock of the constant pressure dropping funnel was opened, and 57.4g of benzoyl chloride was added dropwise, keeping the reaction temperature between 60°C and 85°C. The benzoyl chloride was dropped in about 1.5 hours. After the dropwise addition, the reflux reaction was continued and samples were taken to track the reaction process. When the mass fraction of benzoyl chloride in the reaction solution was less than 0.1%, the reaction was over, and it took about 4 hours. After cooling down to 35°C-45°C, filter, wash the filter residue twice with 40mL tol...

Embodiment 4

[0023] The synthetic method of embodiment four benzoyl cyanides

[0024] Put 100mL of toluene, 23.7g of 97% solid sodium cyanide, 0.3g of polyethylene glycol 600, 0.3g of trioctylmethylammonium chloride, and 0.6g of water into a 250mL four-necked flask, turn on the tail gas absorption device, stir, Circulating cooling water. Turn on the heating device and start heating. When the temperature of the reaction solution rose to 85°C, the cock of the constant pressure dropping funnel was opened, and 57.4g of benzoyl chloride was added dropwise, taking care to maintain the reaction temperature between 85°C and 110°C. The benzoyl chloride was dropped in about 1.5 hours. After the dropwise addition, the reflux reaction was continued and samples were taken to track the reaction process. When the mass fraction of benzoyl chloride in the reaction solution was less than 0.1%, the reaction was over, and it took about 4 hours. After cooling down to 35°C-45°C, filter, wash the filter residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com