Method for preparation of 5-hydroxymethylfurfural catalyzed by methyltrioxorhenium

A technology of methyl rhenium trioxide and hydroxymethylfurfural, which is applied in organic chemistry and other fields, can solve problems not involved in catalytic dehydration of six-carbon sugars, and achieve high selectivity, improved conversion rate and selectivity, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

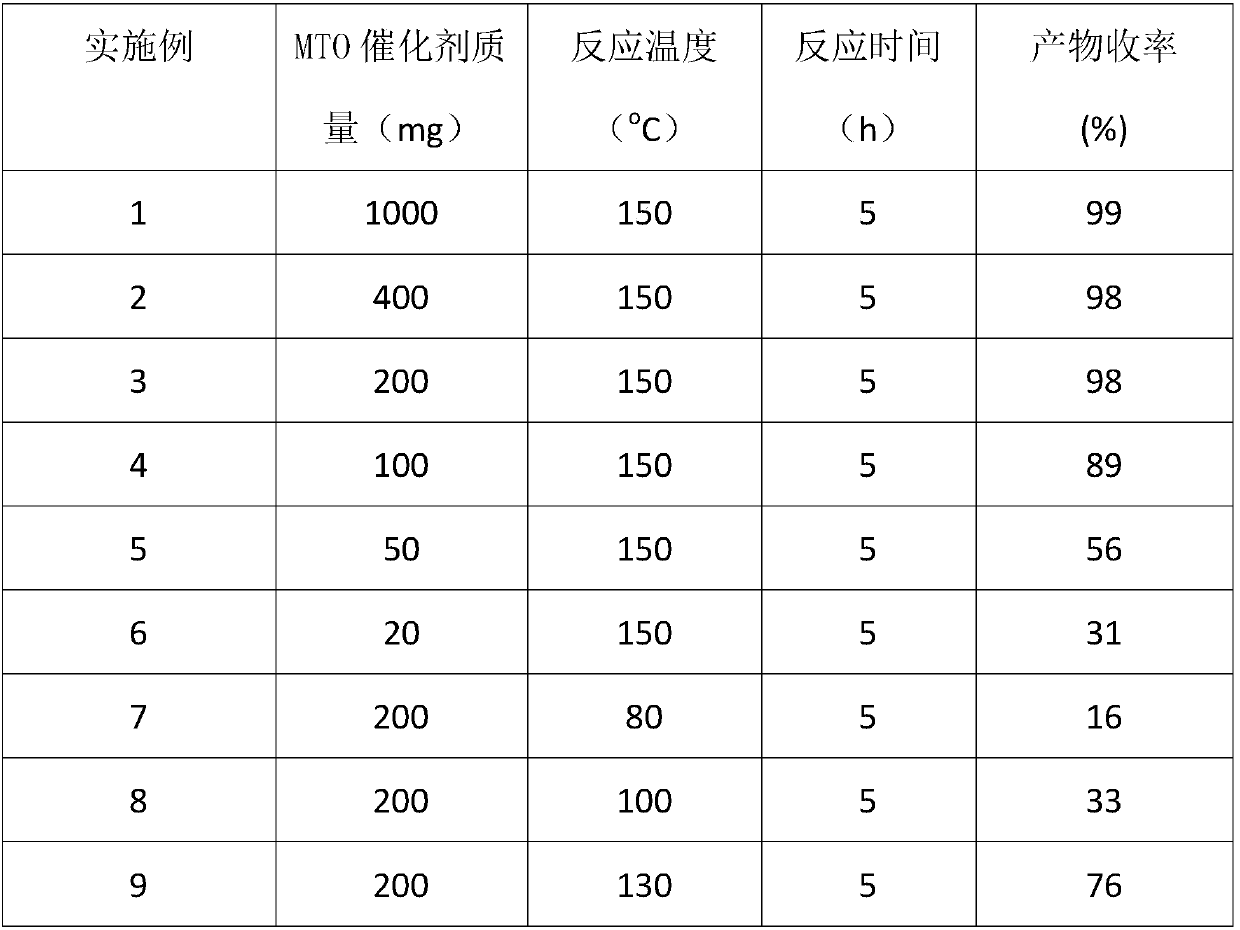

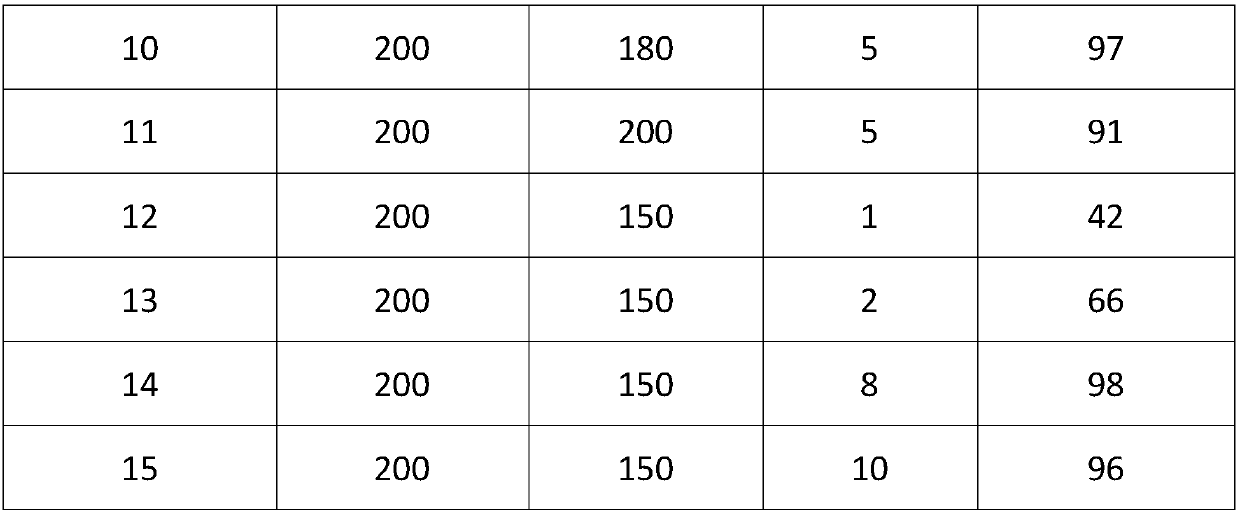

[0019] Add 2 grams of fructose, a certain amount of MTO and 20 grams of tetrahydrofuran into the reaction kettle respectively, seal it, stir and heat to the set reaction temperature, carry out stirring reaction at a speed of 1000 rpm for a certain period of time, and then stop the reaction. The reaction mixture sample was filtered, and the filtrate was analyzed by a liquid chromatograph through an ultraviolet detector. The reaction results are shown in Table 1.

[0020] Table 1. The reaction results of MTO catalyzing the conversion of fructose to HMF under different conditions in tetrahydrofuran solvent

[0021]

[0022]

[0023] The above examples show that: MTO in tetrahydrofuran solvent catalyzes the conversion of fructose to prepare HMF under the above different conditions and obtains good reaction results.

Embodiment 16~20

[0025] Add 2 grams of reaction substrate, 200 mg of catalyst MTO and 20 grams of tetrahydrofuran into the reaction kettle respectively, seal it and heat it to 150° C. with stirring at a speed of 1000 rpm for 5 hours, then stop the reaction. The reaction mixture sample was filtered, and the filtrate was analyzed by a liquid chromatograph through an ultraviolet detector. The reaction results are shown in Table 2.

[0026] Table 2. MTO-catalyzed conversion of different substrates to prepare HMF in tetrahydrofuran solvent

[0027] Example

[0028] Examples 16-20 show that the conversion of different substrates catalyzed by MTO to prepare HMF in tetrahydrofuran solvent has obtained excellent reaction results.

Embodiment 21~26

[0030] Add 2 grams of reaction substrate, 200 mg of catalyst MTO and 20 grams of reaction solvent into the reaction kettle, seal it and heat it to 150° C. with stirring at a speed of 1000 rpm for 5 hours, then stop the reaction. The reaction mixture sample was filtered, and the filtrate was analyzed by a liquid chromatograph through an ultraviolet detector. The reaction results are shown in Table 3.

[0031] Table 3. The reaction results of MTO-catalyzed conversion of fructose to HMF in different solvents

[0032] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com