Quantum dot film and preparation method of alumina-coated quantum dots

A technology of coating quantum and quantum dots, which is applied in the field of quantum dots, can solve the problems of high risk of reaction and unsuitable for industrial production, and achieve the effects of improving stability, good flatness and avoiding erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for preparing alumina-coated quantum dots, the preparation method is:

[0051] Mix the red light CdSe / CdS / CdZnS quantum dot dispersion with a concentration of 50mg / mL and cyclohexane, the volume ratio of cyclohexane to quantum dot dispersion is 1000:6, and add three Ethyl aluminum solution (1M), the volume ratio of described triethyl aluminum solution and quantum dot dispersion liquid is 1:3, under the stirring of 300rpm, react 2h, after reaction finishes, sample is taken out from glove box, uses reaction The obtained alumina-coated quantum dots were washed three times with cyclohexane, and then dried at 60° C. to obtain pure alumina-coated red CdSe / CdS / CdZnS quantum dots.

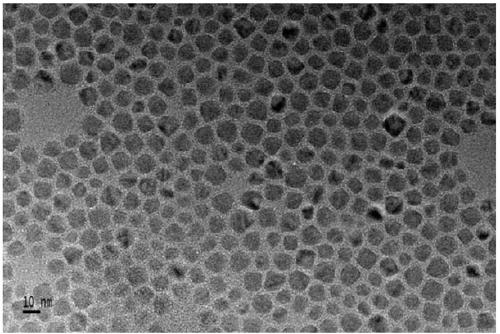

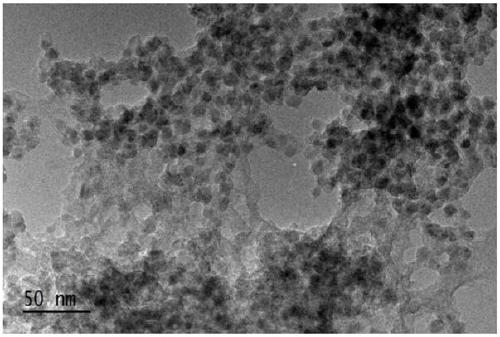

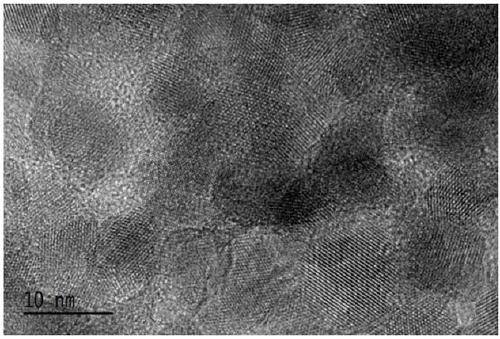

[0052] The TEM image of the alumina-coated red CdSe / CdS / CdZnS quantum dots prepared in this example is as follows figure 2 As shown, it can be seen that alumina can effectively coat quantum dots, and at the same time, there are no obvious free quantum dots in the ...

Embodiment 2

[0054] This embodiment provides a preparation method of alumina-coated quantum dots, the preparation method is:

[0055] The green light alloy CdZnSeS quantum dot dispersion liquid with a concentration of 30mg / mL is mixed with n-hexane, and the volume ratio of n-hexane and quantum dot dispersion liquid is 1000:1, and triethylaluminum solution is added dropwise in a nitrogen state glove box ( 0.5M), the volume ratio of the triethylaluminum solution and the quantum dot dispersion liquid is 1:5, react 3h under the stirring of 100rpm, after the reaction finishes, the sample is taken out from the glove box, use normal hexane to react The obtained alumina-coated quantum dots were washed 5 times, and then dried at 80° C. to obtain pure alumina-coated green light alloy CdZnSeS quantum dots.

Embodiment 3

[0057] This embodiment provides a preparation method of alumina-coated quantum dots, the preparation method is:

[0058] Mix the green light alloy CdZnSeS quantum dot dispersion with a concentration of 80mg / mL and chloroform, the volume ratio of chloroform and quantum dot dispersion is 1000:10, add triethylaluminum solution (2M) dropwise in a nitrogen state glove box , the volume ratio of the triethylaluminum solution to the quantum dot dispersion is 1:8, reacted for 6h under stirring at 500rpm, after the reaction, the sample was taken out from the glove box, and the reaction was carried out using chloroform to obtain the The alumina-coated quantum dots were washed once, and then dried at 50°C to obtain pure alumina-coated green light alloy CdZnSeS quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com