Cow leather treatment process

A treatment process, leather technology, applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather/fur mechanical treatment, etc. It can solve the problem of smooth and bright leather surface losing naturalness, etc. problem, to achieve the effect of natural and beautiful texture, prolonging the service life and prolonging the existence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

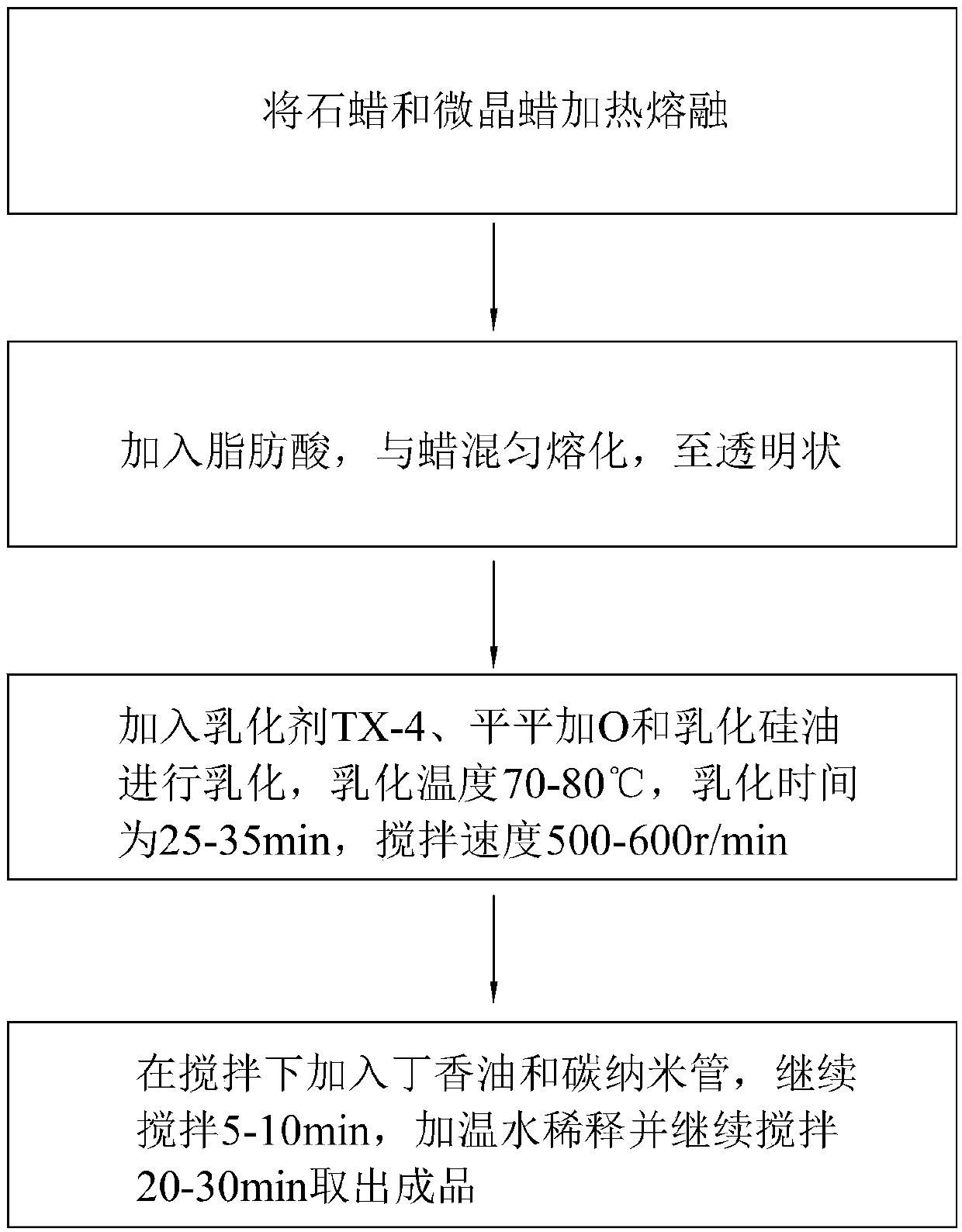

[0064] A process for treating bovine leather, comprising the steps of:

[0065] Step 1, spray cationic, spray the cationic slurry on the front of the leather, after drying, spray the cationic slurry evenly once, and dry;

[0066] Step 2, ironing the leather, put the leather face up on the conveyor belt and roll it to level off, the temperature of the roll is 130°C, and the pressure is 20-30kg;

[0067] Step 3, softening, putting the leather into the softening drum, softening for 30 hours;

[0068] Step 4, stretching the board, stretching the leather on the stretching machine;

[0069] Step 5, second scalding, put the leather face up on the conveyor belt and roll it to level off, the temperature of the roll is 130°C, and the pressure is 10-20kg;

[0070] Step 6, spray the surface slurry, spray the surface slurry evenly on the front of the leather, spray the surface slurry again after drying, then dry, spray the third time, and dry;

[0071] Step 7, spray light, evenly spray ...

Embodiment 2

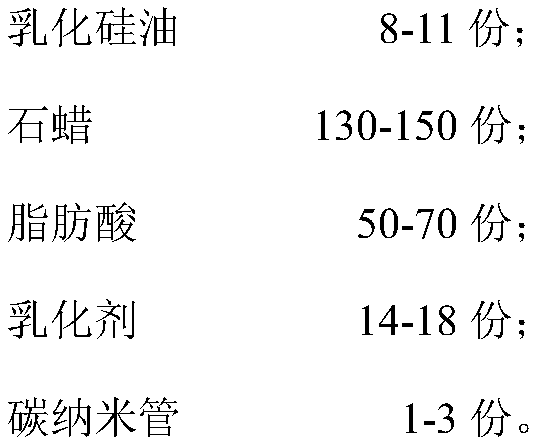

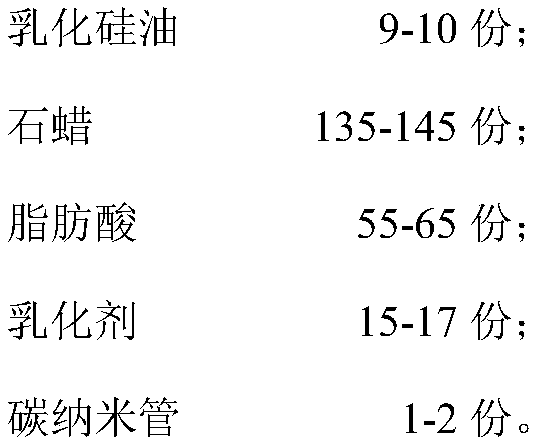

[0084] The difference from Example 1 is that, in parts by weight, the raw material components of the hand feeling agent are shown in Table 1.

Embodiment 3

[0086] The difference from Example 1 is that, in parts by weight, the raw material components of the hand feeling agent are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com