A kind of anti-perovskite manganese nitrogen compound/aluminum double connected structure composite material and preparation method thereof

A technology of manganese nitrogen compound and anti-perovskite, which is applied in the field of anti-perovskite manganese nitrogen compound/aluminum double-connected structure composite material and its preparation, which can solve the problems of high temperature and low density of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

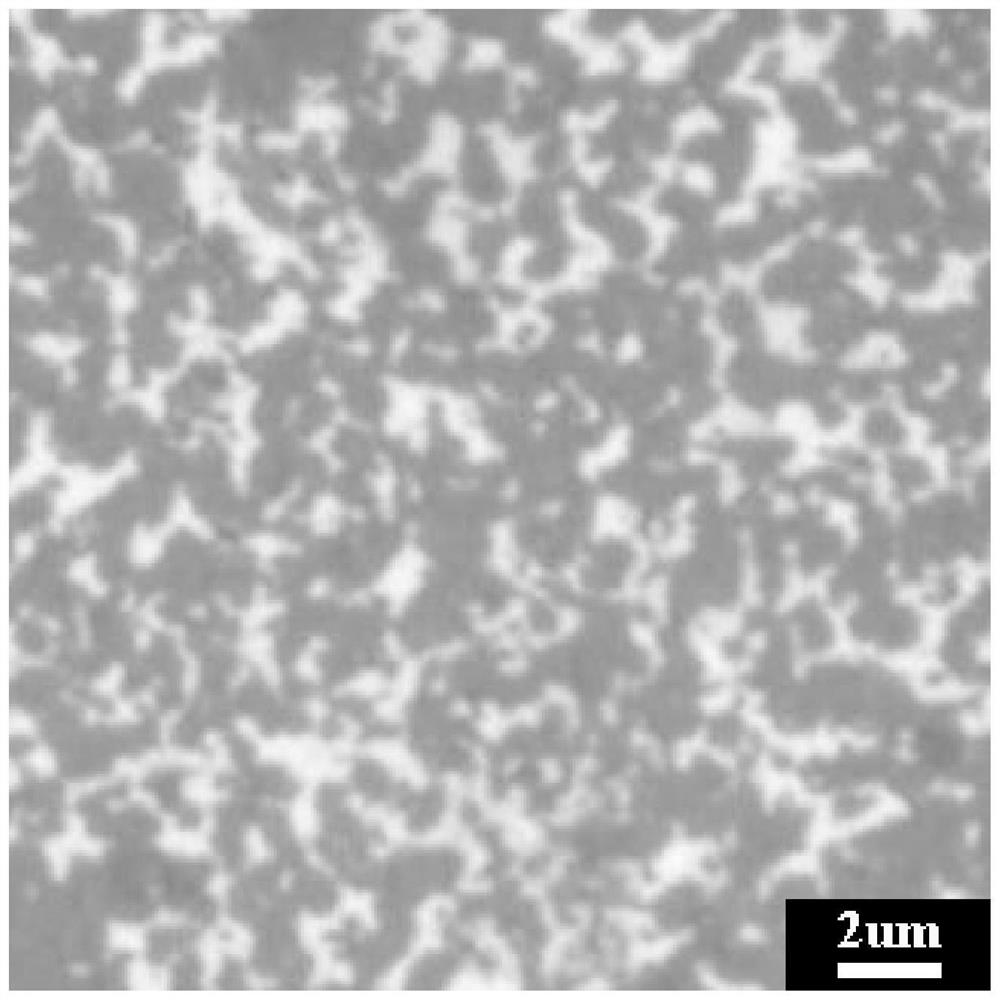

[0022] Specific Embodiment 1: In this embodiment, the antiperovskite manganese nitrogen compound / aluminum double-connected structure composite material is composed of a reinforcement and a matrix metal, and the reinforcement is Mn 3 Zn 1-x A x N particles, wherein A is Ge or Sn, x=0.3-0.7; the base metal is pure aluminum or aluminum alloy.

[0023] The principles and beneficial effects of this embodiment are:

[0024] 1. The composite material prepared in this embodiment is a double-connected structure, and the reinforcement in the composite material is Mn 3 Zn 1-x A x N particles, adjacent Mn 3 Zn 1-x A x The N particles are interconnected to form a three-dimensional network frame, and the continuous matrix metal aluminum is filled in the three-dimensional network frame. Since the reinforcement is connected in three-dimensional macroscopically, the reinforcement can not only transmit the load, but also bear the load itself, which makes the performance of the prepared ...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the Mn 3 Zn 1-x A x The volume fraction of N particles is 30-60%. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the Mn 3 Zn 1-x A x The particle size of the N particles is 5 to 50 μm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com