Externally-threaded structure matched with internal thread of wedge-shaped anti-loose thread

A wedge-shaped anti-loosening, external thread technology, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the problems of high contact stress, reduced axial force of external threads, slippery teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

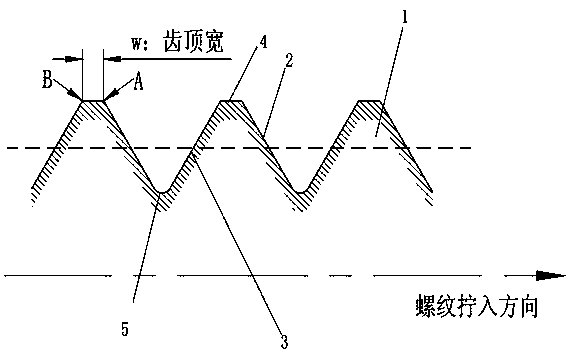

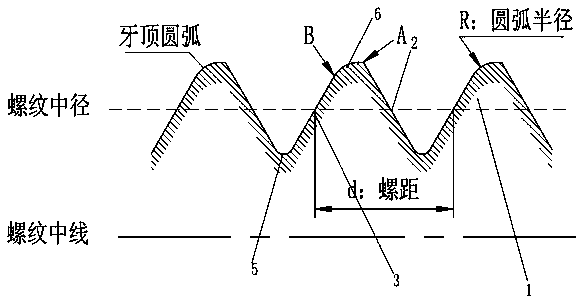

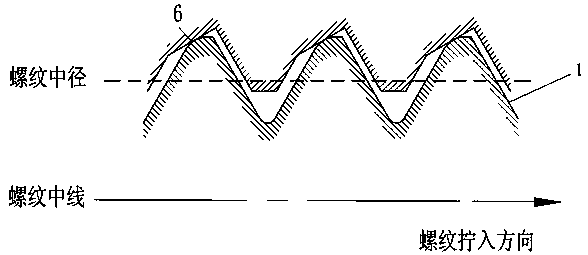

[0019] Such as figure 2 , image 3 As shown, the external thread structure provided by the present invention to cooperate with the internal thread of the wedge-shaped anti-loosening thread includes an external thread body 1, and each external thread on the external thread body 1 includes a leading flank 2, a following flank 3, and The crest 4 and the root 5 extending between the leading flank 2 and the following flank 3, the crest 4 is a circle formed by arc-shaped extension from the leading flank 2 to the junction of the following flank 3 The arc surface 6, and the arc surface 6 can make point contact with the cusp of the internal thread when the external thread and the internal thread are tightened together.

[0020] Through the above-mentioned structural setting, when cooperating with the existing JB / T10971 "30° wedge-shaped anti-loosening thread" internal thread, since the top is provided with a section of arc surface structure, it can be freely tightened when tightening...

Embodiment 2

[0025] The general structure of the external thread structure matched with the internal thread of the wedge-shaped anti-loosening thread provided by this embodiment is the same as that of Embodiment 1, the difference is that further, the arc radius of the arc surface 6 is the pitch of the external thread body 1 One-half of d, ie R=½d.

[0026] Further, the arc of the arc surface 6 is the largest when starting from the end A of the addendum line W, and the smallest when reaching the end B, and the arc length is zero at this time.

Embodiment 3

[0028] The general structure of the external thread structure matched with the internal thread of the wedge-shaped anti-loosening thread provided by this embodiment is the same as that of Embodiment 1, the difference is that further, the arc length of the arc surface 6 is equal to the width W of the addendum, that is Arc length = addendum width W.

[0029] This external thread structure is suitable for external thread structures such as metric system, imperial system and American system.

[0030] When this embodiment is screwed with the thread of JB / T10971 "30° wedge-shaped anti-loosening thread", the arc surface at the cusp of the external thread is pushed against the wedge-shaped slope of the internal thread JB / T10971 "30° wedge-shaped anti-loosening thread" On the surface, a large locking force is generated to achieve the purpose of preventing the nut from loosening. At the same time, the cusp of the external thread is a circular arc surface, which increases the matching sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com